Preparation method of inorganic clay-alkali cellulose water-retaining material

A technology of alkali cellulose and water-retaining materials, applied in soil conditioning materials, organic fertilizers, chemical instruments and methods, etc., can solve problems such as high requirements for preparation conditions and reaction equipment, complex preparation process of superabsorbent resin, and environmental pollution.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

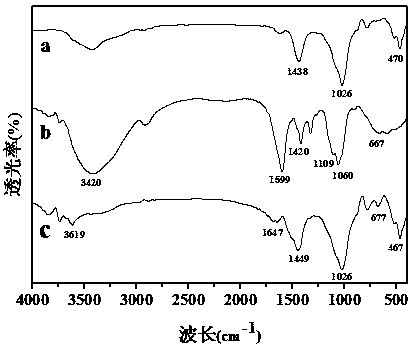

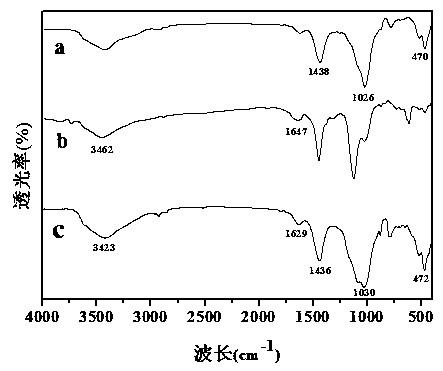

Embodiment 1

[0042] 1. Preparation of inorganic clay-sodium carboxymethyl cellulose soil water retention material

[0043] 1) After removing impurities, loess and laterite are mixed at a mass ratio of 1:0.2, dried, and crushed to 100-200 mesh;

[0044] 2) Take a certain amount of treated loess and laterite mixed soil, add 2.5-4.5% of its mass of sodium carboxymethyl cellulose, mix well, add tap water with 60-85% of the mass of inorganic clay, at 300-600r / min Stir at a stirring speed for 30-60 minutes, dry and pulverize to obtain inorganic clay-sodium carboxymethyl cellulose soil water retention material.

[0045] 3) Prepare inorganic clay-sodium carboxymethyl cellulose water-retaining material into a viscous turbid liquid with a concentration of 0.75g / mL, and then spread it evenly on the upper layer of the soil and press it to form a soil-based water-retaining layer. Under natural conditions, weigh its mass and calculate the water retention rate. At 73.5 hours, the water retention rate o...

Embodiment 2

[0046] Embodiment 2, the preparation of inorganic clay-sodium hydroxymethylcellulose soil water retention material

[0047] 1) After removing impurities, loess and red clay are mixed at a mass ratio of 1:0.5, dried, and crushed to 100-200 mesh;

[0048] 2) Take a certain amount of treated mixed inorganic clay, add 2.5~4.5% of the mass of hydroxymethyl cellulose sodium, mix well, add tap water with 60~85% of the mass of the inorganic clay, and stir at a stirring speed of 300~600r / min Stir under low pressure for 30-60 minutes, dry and pulverize to obtain inorganic clay-sodium hydroxymethylcellulose soil water retention material;

[0049] 3) The inorganic clay-hydroxymethyl cellulose sodium water-retaining material is made into a viscous turbid liquid with a concentration of 0.75g / mL, and then it is evenly spread on the upper layer of the soil and pressed to form a soil-based water-retaining layer. Under natural conditions, weigh its mass and calculate the water retention rate. ...

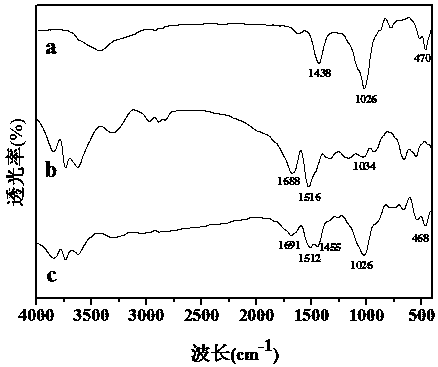

Embodiment 3

[0050] Embodiment three, the preparation of inorganic clay-sodium methylcellulose soil water retention material

[0051] 1) After removing impurities, loess and red clay are mixed at a mass ratio of 1:1, dried, and crushed to 100-200 mesh;

[0052] 2) Take a certain amount of treated mixed inorganic clay, add 2.5-4.5% of its mass of sodium methylcellulose, mix well, add tap water with 60-85% of the mass of inorganic clay, and mix at a stirring speed of 300-600r / min Stir for 30-60 minutes, dry and pulverize to obtain inorganic clay-sodium methylcellulose soil water retention material;

[0053] 3) Prepare inorganic clay-methylcellulose sodium water-retaining material into a viscous turbid solution with a concentration of 0.75g / mL, then evenly spread it on the upper layer of the soil, and press it to form a soil-based water-retaining layer. Under natural conditions, weigh its mass and calculate the water retention rate. At 80 hours, the water retention rate of inorganic clay-so...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com