Formula of shower gel made from Xinhui orange peel and orange flower extract and process

A technology of extract and shower gel, which is applied in the field of cosmetics to achieve the effect of restoring health, accelerating self-renewal and repair, and restoring normal physiological functions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0042] Preparation of raw materials:

[0043] Preparation of citrus citrus peel extract: Cut fresh citrus citrus peel into thin strips, dry in hot air at 55°C, grind into powder, and sieve; take out 100g of dry powder and add 100mL of methanol, and extract at 50°C at an extraction temperature of Under the condition of 300BAR, extract statically for 20min, then add methanol at a rate of 0.4mL / min, extract dynamically for 2h, and concentrate under reduced pressure to obtain 22.2g of Xinhui mandarin peel extract.

[0044] Preparation of Xinhui mandarin flower extract: take 100g fresh Xinhui mandarin flower, dry in hot air at 55°C, grind into powder, and pass through a 40-mesh sieve; the obtained powder is subjected to supercritical extraction of carbon dioxide, the extraction temperature is 55°C, and the extraction pressure 300BAR, among which, first add 95% ethanol according to the ratio of g / mL to 1:1, statically extract for 25min, then add 95% ethanol at 0.4mL / min, and dynamic...

Embodiment 1-4

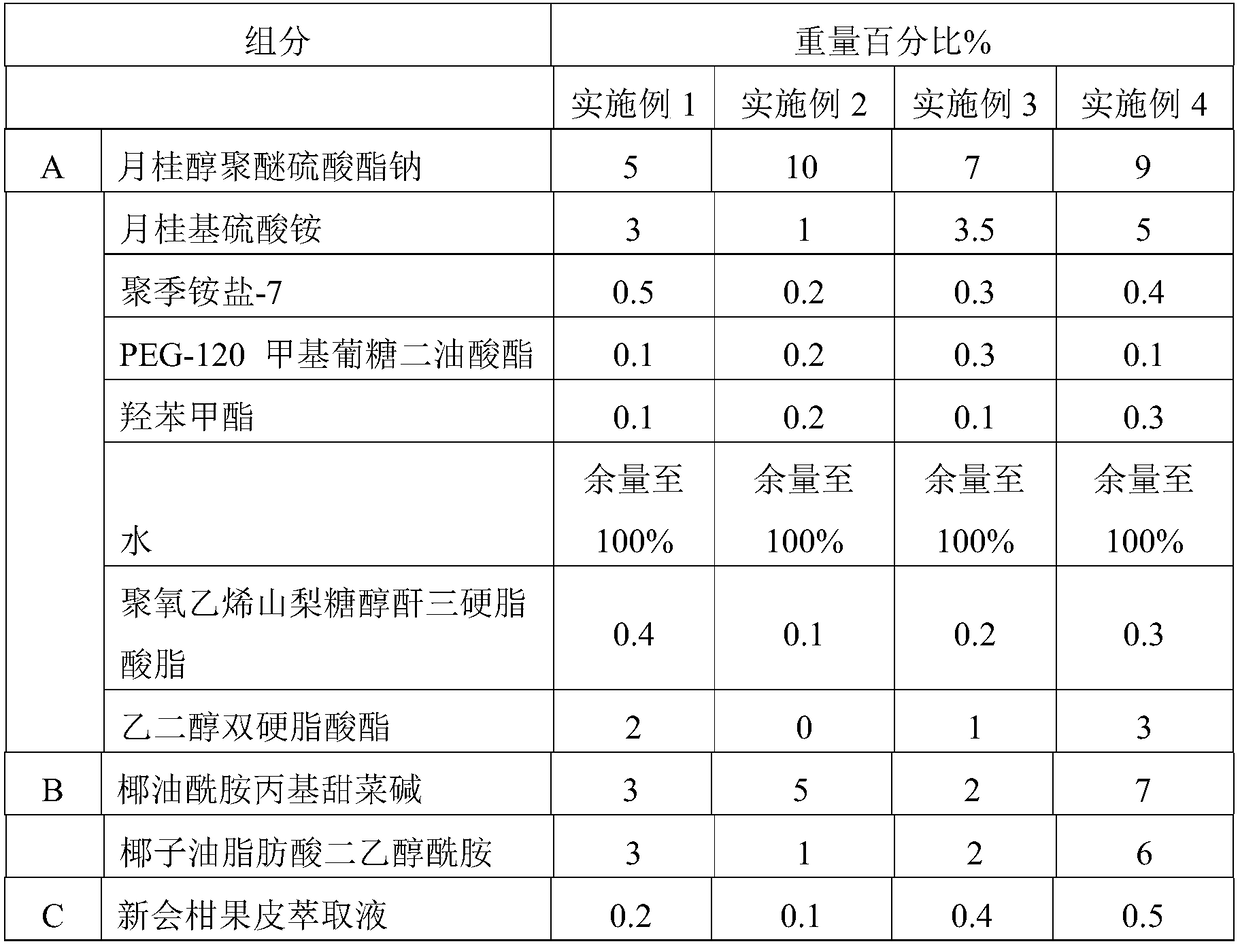

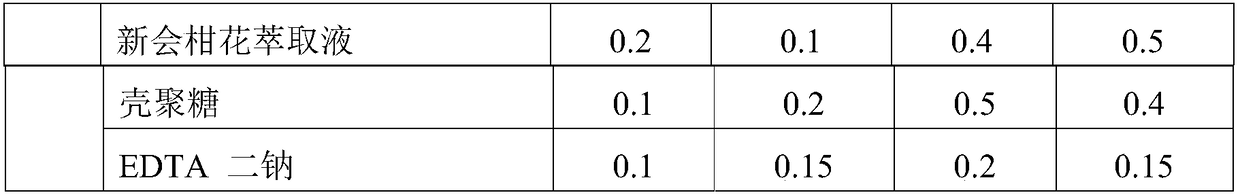

[0047] The formula of shower gel made from the new citrus peel and tangerine flower extract of embodiment 1-4, which comprises the following components in mass percentage, as shown in Table 1 below:

[0048] The formula component (%) of the new citrus fruit peel of table 1 embodiment 1-4 and citrus flower extract making shower gel

[0049]

[0050]

[0051] The preparation process method of embodiment 1-4 is as follows.

[0052] A process for making shower gel from Xinhui mandarin peel and mandarin flower extract, which is prepared according to the following steps:

[0053] 1) Weigh the raw materials of each component, put the deionized water into the jacketed heating barrel and heat up to 50-60°C;

[0054] 2) Emulsification: Put the raw materials of group A into the stirring pot in turn, heat up to 80°C, and stir at a speed of 30 rpm, until the raw materials are completely dissolved; the raw materials of group A include: water, sodium laureth sulfate, lauryl Ammonium ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com