Preparation method for mesoporous bioactive glass/sodium alginate-sodium alginate layered bone tissue engineering scaffold

A technology of bone tissue engineering and sodium alginate, applied in the field of materials science, can solve the problems of poor osteoconductivity, fast drug release, low mechanical strength, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

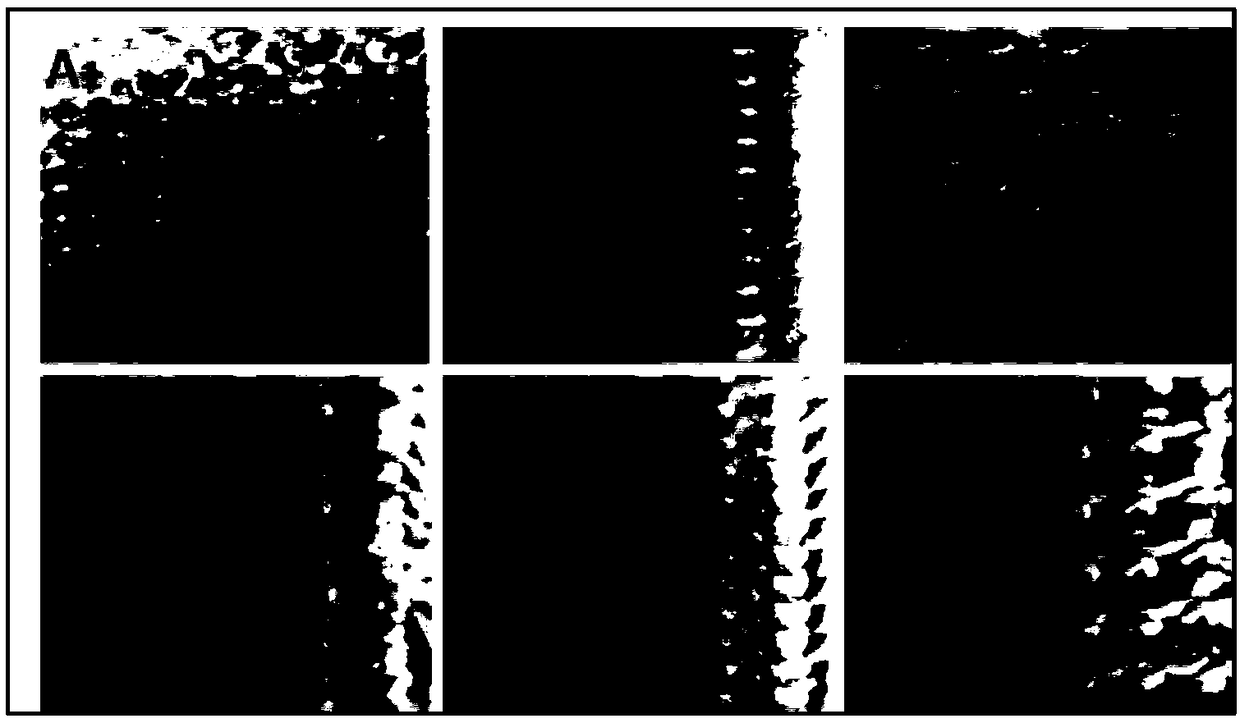

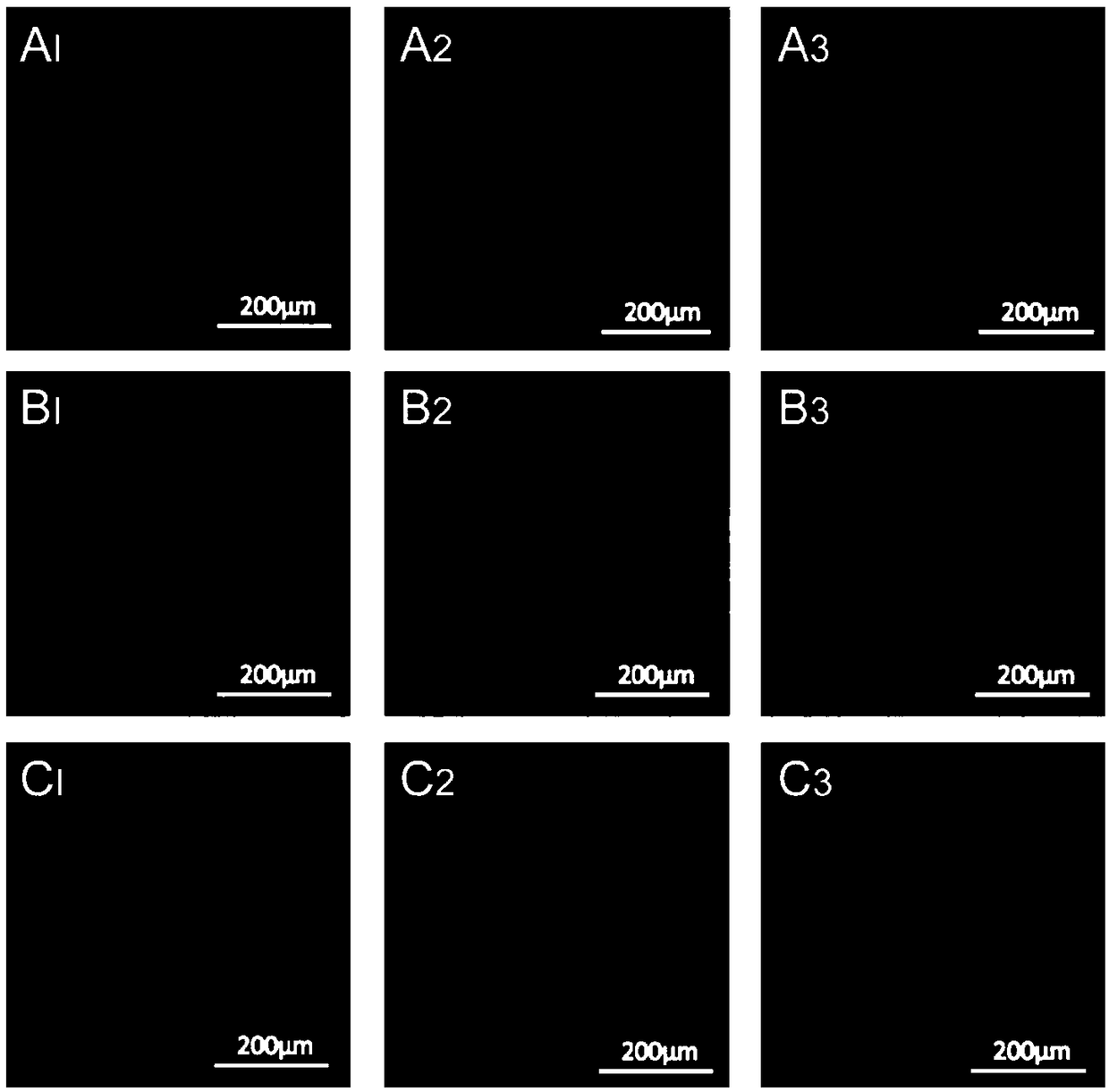

Method used

Image

Examples

Embodiment 1

[0028] A method for preparing a mesoporous bioglass / sodium alginate-sodium alginate layered bone tissue engineering scaffold, comprising the following steps:

[0029] Step 1, preparation of mesoporous bioglass powder: bioactive glass blocks with good mesoporous channels (molar ratio SiO) are prepared by volatilization-induced self-assembly method. 2 :CaO:P 2 O 5 =80:15:5), then ball-milled the mesoporous bioglass blocks, passed through a 400-mesh sieve, the particle size was less than 37 microns, and dried for later use.

[0030] Step 2, preparing sodium alginate layer ink: dissolving sodium alginate in deionized water (25% by mass), and magnetically stirring to obtain a uniformly mixed sodium alginate ink for subsequent three-dimensional printing.

[0031]Step 3, prepare mesoporous bioglass / sodium alginate layer composite ink: dissolve sodium alginate in deionized water to obtain a solution with a mass fraction of 10%, and add the mesoporous bioglass powder obtained in step...

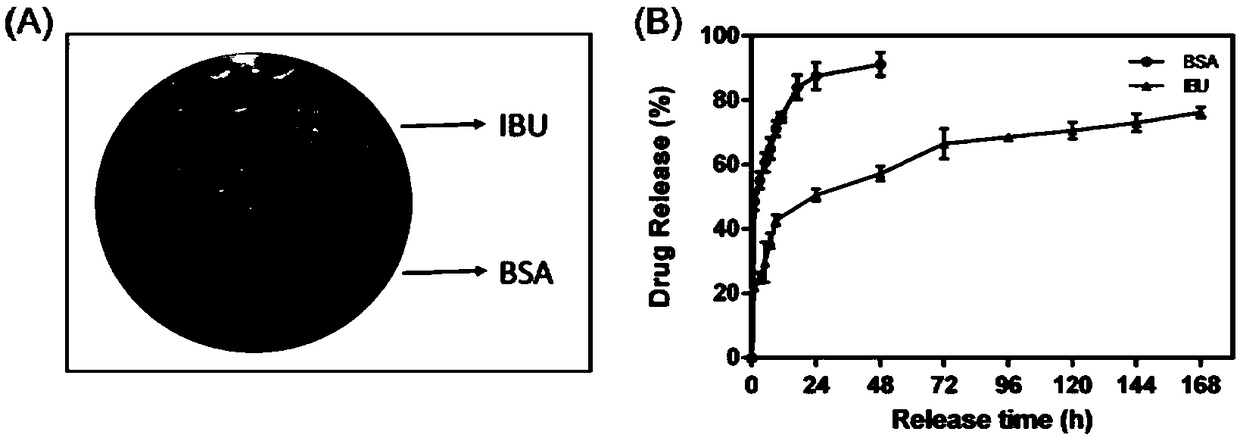

Embodiment 2

[0036] Example 2 Drug Loading and Release Example

[0037] A preparation method of a drug-loaded mesoporous bioglass / sodium alginate-sodium alginate layered bone tissue engineering scaffold, comprising the following steps:

[0038] Step 1, prepare the sodium alginate layer ink loaded with bovine serum albumin (BSA): dissolve the BSA in deionized water to form a uniform solution, and then dissolve the sodium alginate in it to obtain the sodium alginate layer ink loaded with BSA, The mass fraction of sodium alginate is 25%, and the mass fraction of BSA is 2%.

[0039] Step 2, prepare the mesoporous bioglass / sodium alginate layer composite ink loaded with ibuprofen drug (IBU): dissolve the IBU in a small amount of absolute ethanol, and then add deionized water to make the concentration 50 mg / ml. Next, 2.0 g of mesoporous bioglass powder was added to 100 ml of IBU solution and stirred at room temperature for 24 hours, and then centrifuged. The upper layer was taken to measure its...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com