Shape memory epoxy resin modified asphalt mixture and preparation method thereof

A technology of epoxy resin and modified asphalt, applied in the field of material processing, can solve the problems of insufficient anti-deformation ability to resist deformation, not fundamentally solved, limited deformation recovery and self-healing ability of asphalt mixture, and low cost. , environment-friendly, simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

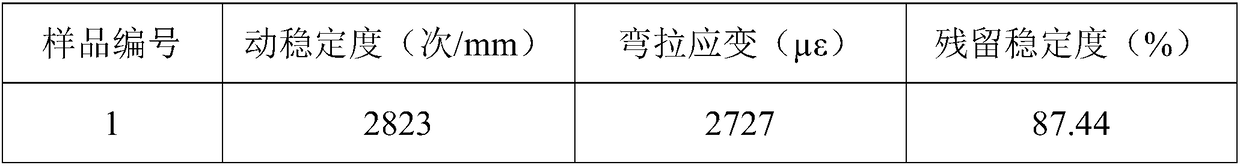

Embodiment 1

[0035] The inventive shape-memory epoxy resin modified asphalt mixture is made of asphalt, aggregate, shape-memory epoxy resin and mineral powder. In parts by mass, it includes 4.8 parts of asphalt, 100 parts of aggregate, 1 part of shape memory epoxy resin and 6 parts of mineral powder. Among them, the asphalt is 90# road petroleum asphalt, the aggregate is diorite gravel, which is composed of coarse material and fine material with a weight ratio of 2:1, the mineral powder is made of limestone; the shape memory epoxy resin is made of bisphenol A ring Oxygen resin (3500) (toughening agent), polypropylene glycol diglycidyl ether, and isophorone diamine (curing agent) are obtained by curing reaction; details are as follows:

[0036]1) Prepolymerize the epoxy resin and the toughening agent at 60°C for 30 minutes to obtain a prepolymer;

[0037] 2) According to the content of the epoxy resin, add a curing agent to the prepolymer to carry out a pre-curing reaction with the hydroge...

Embodiment 2

[0042] The difference between this embodiment and Example 1 is that the shape memory epoxy resin is made of bisphenol F type epoxy resin (4500), resorcinol bisglycidyl ether, phthalene The amines are prepared by a curing reaction; the glass transition temperature of the shape memory epoxy is 45°C.

[0043] The preparation method of the shape-memory epoxy resin modified asphalt mixture in this embodiment is the same as that in Embodiment 1.

Embodiment 3

[0045] The difference between this example and Example 1 is that the shape-memory epoxy resin is made by curing reaction of novolac epoxy resin (6000), linoleic acid dimer diglycidyl ether, and diethylenetriamine , the glass transition temperature of the shape memory epoxy resin is 50°C.

[0046] The preparation method of the shape-memory epoxy resin asphalt mixture of this embodiment is the same as that of Embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Glass transition temperature | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

| Glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com