Foaming cement, preparation method and application thereof

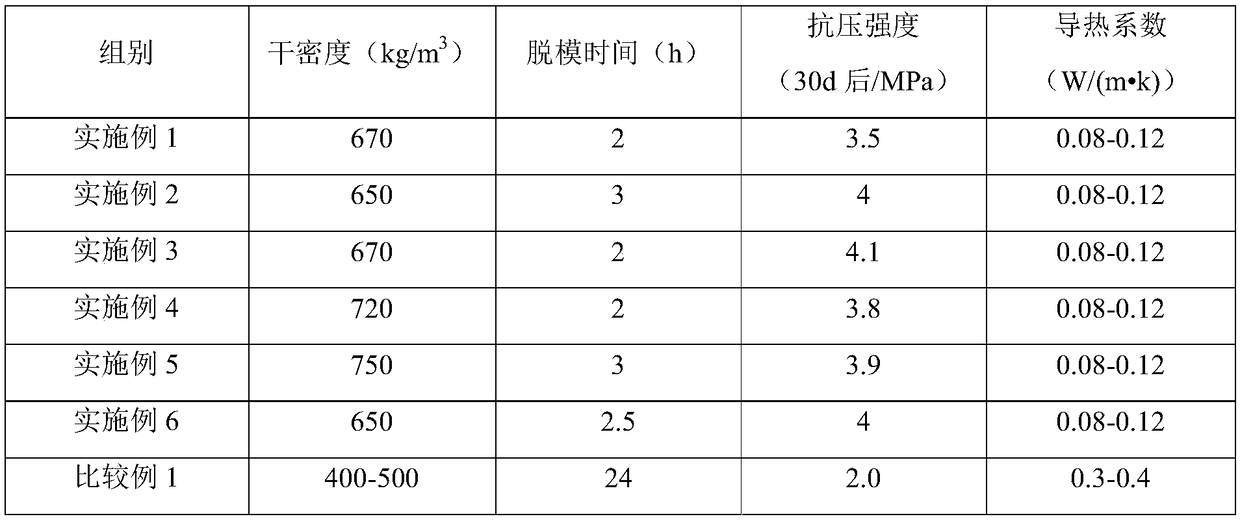

A foamed cement and cement technology, which is applied in the field of cement processing and manufacturing, can solve the problems of poor block strength, thermal conductivity and flame retardant properties, long demolding time affecting production efficiency, uneven distribution of particles as a whole, etc. The effect of long, improved wrapping, and simple operation steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] 1) Batching calculation: determine the wet bulk density of the block, and calculate the amount of various raw materials according to the set bulk density and the density of various raw materials;

[0033] 2) The quality of various raw materials (cement, mineral powder, glass microspheres, sulphoaluminate strength reduction agent, EPS particles, external additives and water, etc.) calculated in strict accordance with the above steps shall be measured and dosed with a weighing scale. The quality of raw materials is: 1kg of cement, 10kg of EPS granules, 3kg of sulphoaluminate accelerator and shrinkage reducer, 7kg of cellulose ether, 2kg of mineral powder, 4kg of glass beads, 1kg of pH regulator, 0.5kg of stabilizer, and 0.5kg of antioxidant , water 20kg;

[0034] 3) Stirring and forming: Put the measured cement, mineral powder, glass beads, sulphoaluminate strength shrinkage reducing agent, external additives and water into the horizontal mixer, stir for about 2 minutes, ...

Embodiment 2

[0037] 1) Batching calculation: determine the wet bulk density of the block, and calculate the amount of various raw materials according to the set bulk density and the density of various raw materials;

[0038] 2) Calculate the quality of various raw materials (cement, mineral powder, glass beads with a particle size of 2 μm, sulphoaluminate strength reduction agent, EPS particles, external additives and water, etc.) calculated in strict accordance with the above steps, and use a weighing scale to measure the ingredients , The quality of each raw material weighed is: 30kg of cement, 5kg of EPS particles, 6kg of sulphoaluminate accelerator and shrinkage reducer, 4kg of cellulose ether, 10kg of mineral powder, 3kg of glass beads, 0.5kg of pH regulator, and 0.3kg of stabilizer , antioxidant 0.2kg, water 30kg;

[0039] 3) Stirring and forming: Put the measured cement, mineral powder, glass beads, sulphoaluminate strength shrinkage reducing agent, pH regulator, stabilizer and wate...

Embodiment 3

[0042] 1) Batching calculation: determine the wet bulk density of the block, and calculate the amount of various raw materials according to the set bulk density and the density of various raw materials;

[0043] 2) Calculate the quality of various raw materials (cement, mineral powder, glass beads with a particle size of 90 μm, sulphoaluminate strength reduction agent, EPS particles, external additives and water, etc.) calculated in strict accordance with the above steps, and use a weighing scale to measure the ingredients , The quality of each raw material weighed is: cement 20kg, EPS granules 7kg, sulfoaluminate strengthening shrinkage reducing agent 5kg, cellulose ether 5kg, mineral powder 8kg, glass beads 3.8kg, pH regulator 0.5kg, stabilizer 0.5 kg, antioxidant 0.5kg, water 28kg;

[0044] 3) Stirring and forming: Put the measured cement, mineral powder, glass beads, sulphoaluminate strength shrinkage reducing agent, stabilizer, antioxidant and water into the horizontal mi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com