Method for preparing nickel-cobalt solution for synthesizing ternary precursor by using nickel-cobalt sulphide ore

A nickel-cobalt sulfide and precursor technology, applied in the field of metallurgy, can solve the problems of complex steps in synthesizing ternary precursors, high cost, and difficult utilization of nickel-cobalt sulfide ore, and achieve high leaching efficiency, short process and simple equipment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

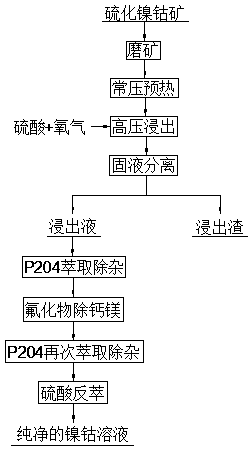

Image

Examples

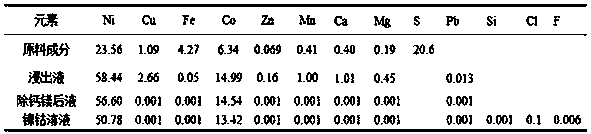

Embodiment 1

[0030] Step 1, ore grinding: the nickel-cobalt sulfide ore is ground to a particle size of 40 mesh;

[0031] Step 2, leaching: the nickel-cobalt sulfide ore after grinding is slurried with water, the volume-to-mass ratio of liquid to solid is 4:1, transferred to an autoclave, and preheated at normal pressure, the preheating temperature is 70°C, and an appropriate amount of Sodium lignosulfonate and sulfuric acid are fed with oxygen and leached under the condition of oxygen pressure of 0.6MP. The leaching temperature is 140°C and the leaching time is 6h. After the leaching is completed, solid-liquid separation is carried out to obtain the leaching solution, and the iron forms hematite. slag removal;

[0032] Step 3, extraction and removal of impurities from the leachate: take the leachate, extract and remove copper, zinc, manganese, iron, calcium, magnesium and lead with P204, and obtain a solution after removal of impurities by P204;

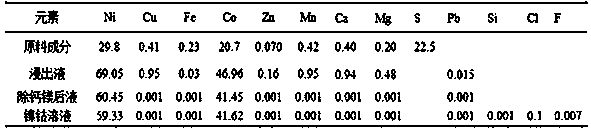

Embodiment 2

[0039] Step 1, ore grinding: the nickel-cobalt sulfide ore is ground to a particle size of 80 mesh;

[0040] Step 2, leaching: the nickel-cobalt sulfide ore after grinding is slurried with water, the volume-to-mass ratio of liquid to solid is 8:1, transferred to an autoclave, and preheated at normal pressure, the preheating temperature is 90°C, and an appropriate amount of Sodium lignosulfonate and sulfuric acid are fed with oxygen and leached under the condition of oxygen pressure of 0.8MP. The leaching temperature is 160°C and the leaching time is 2 hours. slag removal;

[0041] Step 3, extraction and removal of impurities from the leachate: take the leachate, extract and remove copper, zinc, manganese, iron, calcium, magnesium and lead with P204, and obtain a solution after removal of impurities by P204;

[0042] Step 4. Calcium and magnesium removal: After P204 removes impurities, add ammonium fluoride 1.5 times the theoretical amount to further remove calcium and magnesi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com