Method for rapidly determining lithium oxide, potassium oxide and sodium oxide in continuous casting mold fluxes

A continuous casting mold slag and rapid determination technology, applied in the field of chemical inspection, can solve the problems of no lithium oxide, limitations of atomic absorption method, cumbersome analysis steps, etc., achieve the reduction of reagent consumption, accurate and reliable measurement results, simple and fast operation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

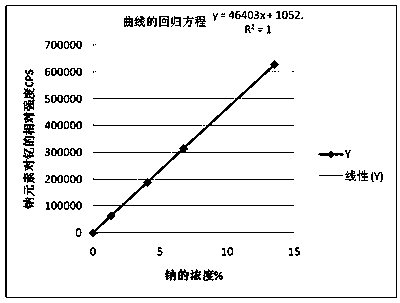

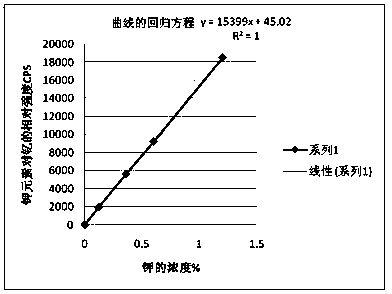

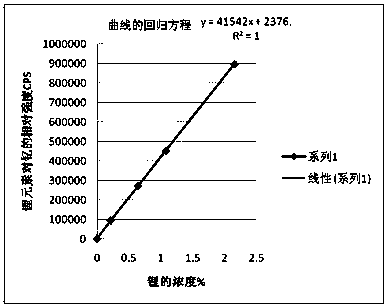

Method used

Image

Examples

Embodiment 1

[0035] In this embodiment, a rapid determination method for lithium oxide, potassium oxide, and sodium oxide in continuous casting mold flux comprises the following steps:

[0036] (1) Decomposition treatment of continuous casting mold flux: the mold flux sample is dried at 105-110°C for 1.5-2 hours, cooled to room temperature in a desiccator, and ground to prepare a mold flux sample with a particle size of ≤0.097mm;

[0037] Weigh 0.1000g mold powder sample into a 500mL polytetrafluoroethylene beaker, rinse the beaker wall with 20mL ultrapure water, add 5mL nitric acid, 5mL hydrochloric acid, 5mL hydrofluoric acid, 5mL perchloric acid, heat and decompose on a low-temperature electric heating plate, Take off the perchloric acid fume and cool it down;

[0038] (2) Preparation of mold flux sample solution: add 5mL hydrochloric acid to the cooled beaker and heat on a low-temperature electric heating plate at 150°C to dissolve the salts, remove the beaker, cool to room temperature...

Embodiment 2

[0061] In this embodiment, a rapid determination method for lithium oxide, potassium oxide, and sodium oxide in continuous casting mold flux comprises the following steps:

[0062] (1) Decomposition treatment of continuous casting mold flux: the mold flux sample is dried at 105-110°C for 1.5-2 hours, cooled to room temperature in a desiccator, and ground to prepare a mold flux sample with a particle size of ≤0.097mm;

[0063] Weigh 0.2000g mold powder sample into a 500mL polytetrafluoroethylene beaker, rinse the beaker wall with 15mL ultrapure water, add 6mL nitric acid, 6mL hydrochloric acid, 5mL hydrofluoric acid, 6mL perchloric acid, heat and decompose on a low-temperature electric heating plate, Take off the perchloric acid fumes and let it cool down;

[0064] (2) Preparation of mold flux sample solution: add 5mL hydrochloric acid to the cooled beaker and heat on a low-temperature electric heating plate at 200°C to dissolve the salts, remove the beaker, cool to room temper...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com