Method for preparing single-layer multilayer graphene thermoelectric detector through laser ablation

A multi-layer graphene, pyroelectric detector technology, applied in the manufacture/processing of thermoelectric devices, final product manufacturing, sustainable manufacturing/processing, etc., can solve the problems of complex preparation process, achieve simple overall structure and fast response speed , easy to achieve effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

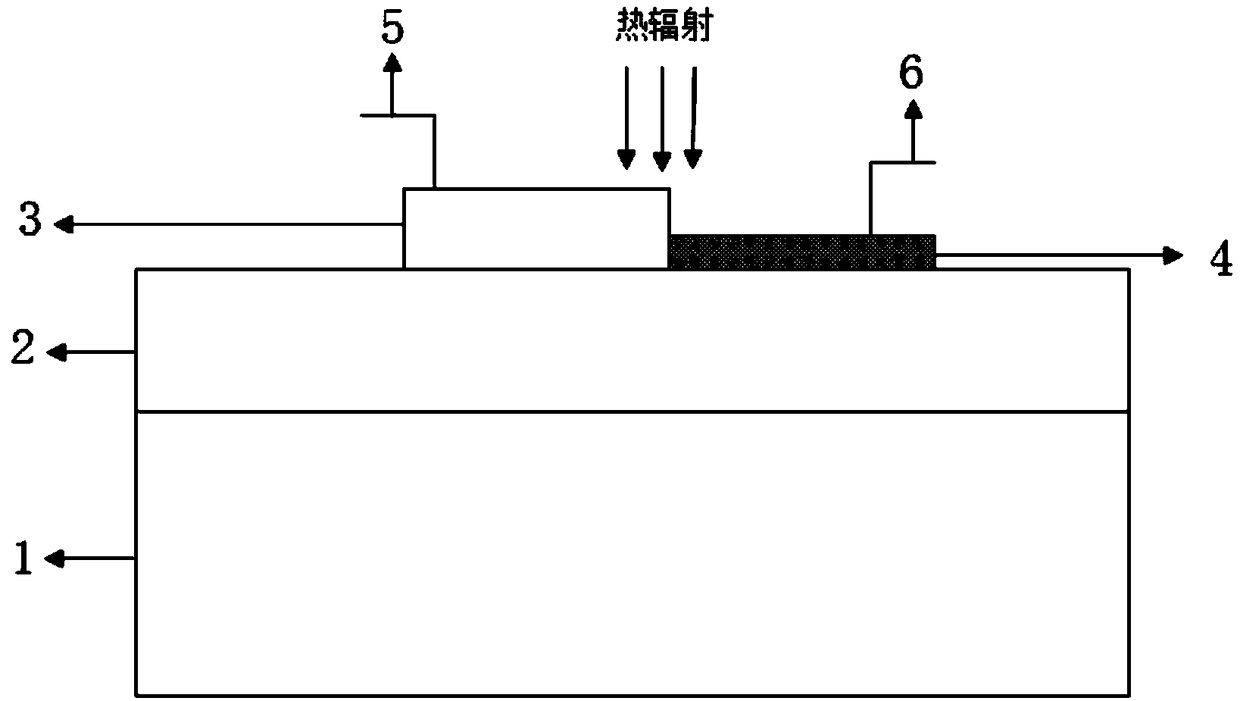

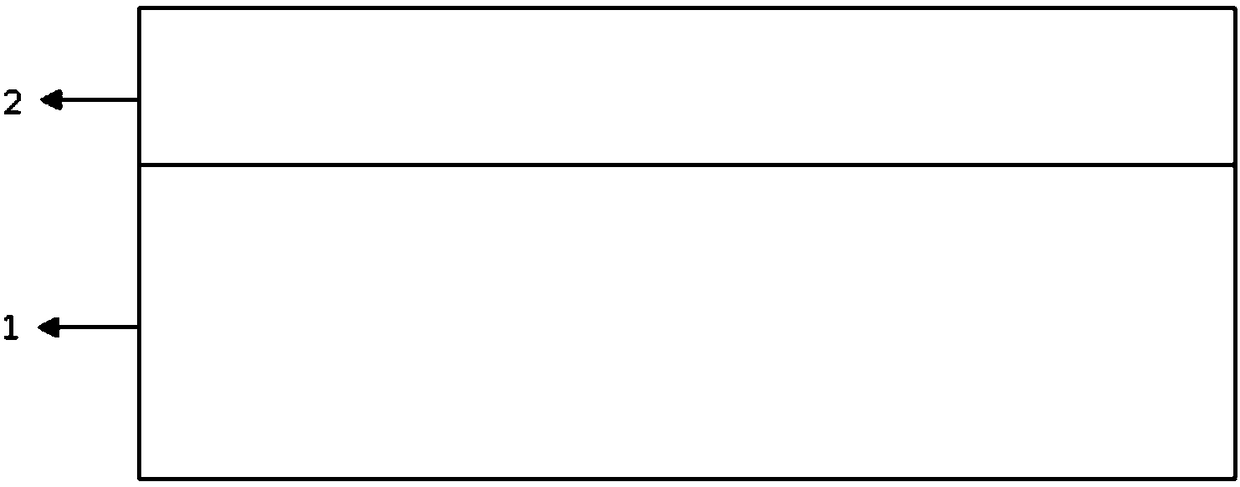

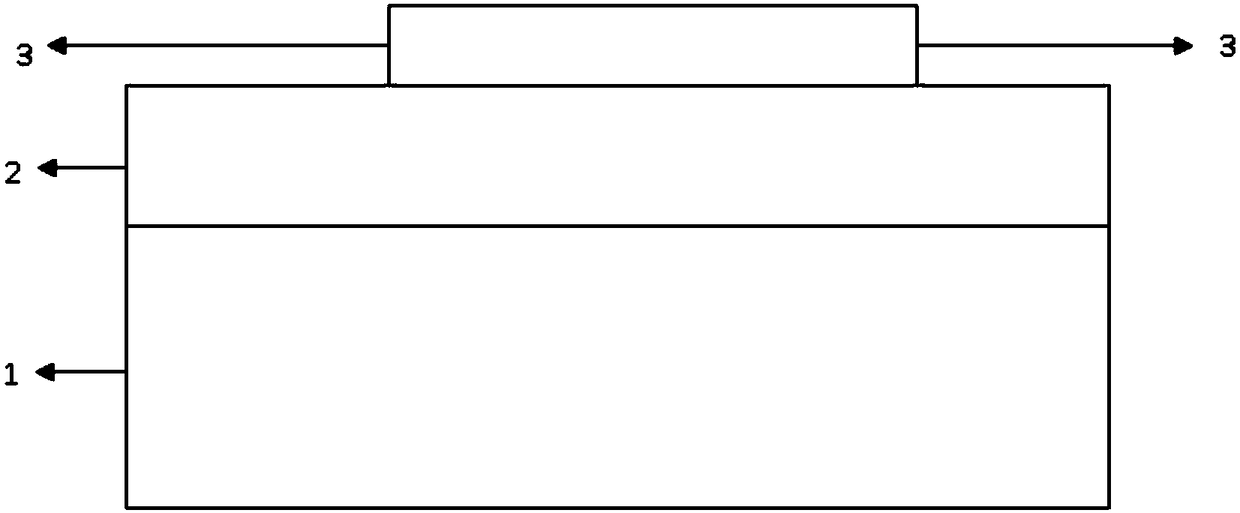

[0031] Such as figure 1 As shown, the graphene monolayer multilayer pyroelectric detector prepared by laser ablation, refer to Figure 2-4 The preparation steps of the thermoelectric device are as follows: growing a layer of insulating dielectric layer 2 on the substrate material 1, transferring a layer of multilayer graphene layer 3 on the insulating dielectric layer 2, and performing laser direct writing on the multilayer graphene layer 3 The ablated multi-layer graphene layer 3 becomes a single-layer graphene layer 4.

[0032] Deposit the first metal electrode 5 at one end of the multilayer graphene layer 3 without ablation, and deposit the second metal at one end of the thin film from the multilayer graphene layer 3 to the single layer graphene layer 4 after laser ablation Electrode 6. Based on the characteristics of multi-layer graphene film thinned into single-layer graphene film after laser ablation, a multi-layer-single-layer graphite heterostructure is generated ins...

Embodiment 2

[0036] In this embodiment, the material of the substrate is flexible polyethylene naphthalate, the dielectric layer is a silicon nitride dielectric layer, and the thickness of the silicon nitride dielectric layer is 100 nm; the thickness of the multilayer graphene 3 is 20 nm.

[0037] During the preparation, the multilayer graphene was obtained by standard mechanical exfoliation process, and then transferred to the silicon nitride dielectric layer, and then the multilayer graphene layer was ablated with a laser energy of 20 mW. Finally, the electron beam evaporation method was used to separate A metal diaphragm is deposited on one end of the multi-layer graphene and one end of the single-layer graphene, and then a first metal electrode and a second metal electrode are manufactured through a lift-off process. In this embodiment, the first metal electrode and the second metal electrode both have a thickness of 100 nm and are made of aluminum. All the other are with embodiment 1....

Embodiment 3

[0039] In this embodiment, the material of the substrate is polyimide, the dielectric layer is an alumina dielectric layer, and the thickness of the alumina dielectric layer is 200nm; a multi-layer two-dimensional material layer is transferred on the dielectric layer, and the two-dimensional material The layer is a multilayer molybdenum disulfide thin film, and the thickness of the molybdenum disulfide layer is 16 nm.

[0040] During preparation, a multilayer molybdenum disulfide thin film is prepared by a high-temperature vacuum synthesis method, and then transferred to an alumina dielectric layer, and then a laser is used to irradiate the multilayer molybdenum disulfide thin film, and the laser energy is 10 milliwatts. Finally, a metal diaphragm is deposited on one end of the non-ablated multi-layer molybdenum disulfide film 3 and the ablated single-layer molybdenum disulfide film by thermal evaporation, and then the first metal diaphragm is made through a lift-off process. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com