Foliar fertilizer and preparation and application methods thereof

A foliar fertilizer, application method technology, applied in the direction of fertilization method, application, organic fertilizer, etc., can solve the problems of unable to meet the sustainable development of agriculture, unable to meet farmers' increase in production and income, unable to provide crop nutrient elements, etc., to improve photosynthesis Strength, improving drought resistance, improving fruit set and seed setting rates

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

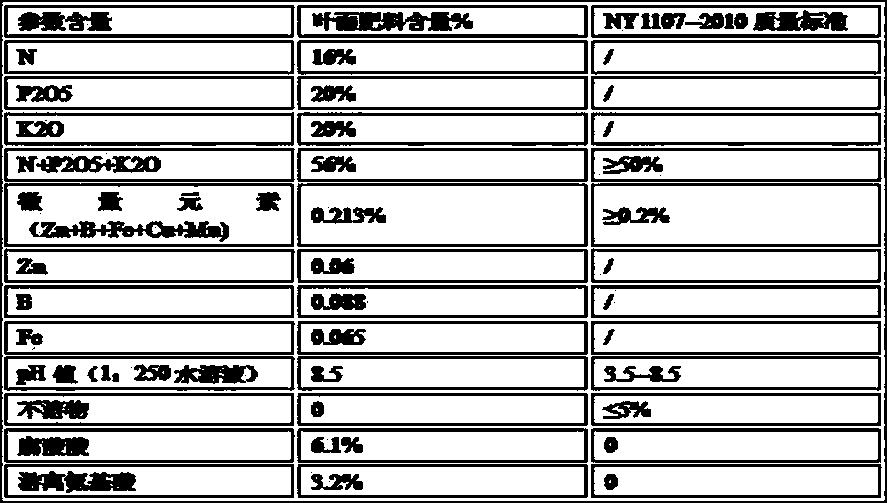

[0034] Provide a special foliar fertilizer for yam, including the components: in terms of mass percentage, potassium dihydrogen phosphate is 21.5%, dipotassium hydrogen phosphate is 18%, potassium tripolyphosphate is 5%, urea is 32.5%, humic 12.5% of acid, 8.5% of amino acid, 0.5% of EDTA-Mg, 0.5% of EDTA-Zn, 0.5% of EDTA-Fe, and 0.5% of boric acid.

[0035] A kind of production technology of foliage fertilizer, its concrete steps are as follows:

[0036] (1) Prepare raw materials: prepare appropriate amount of required raw materials as needed;

[0037] (2) Pulverize potassium dihydrogen phosphate, dipotassium hydrogen phosphate, potassium tripolyphosphate, urea, humic acid, amino acid, boric acid, EDTA-Mg, EDTA-Zn, EDTA-Fe of the prescribed amount respectively, and then pass 20- 40 mesh sieve to get powder;

[0038] (3) Add the powder obtained in step 2) into a mixer, and mix at a speed of 30-50 rpm for 5 minutes until uniform, and obtain an instant foliar fertilizer.

...

Embodiment 2

[0042] Provide a special foliar fertilizer for yam, including the components: in terms of mass percentage, potassium dihydrogen phosphate is 26.5%, dipotassium hydrogen phosphate is 20%, potassium tripolyphosphate is 10%, urea is 20.5%, humic 12% acid, 9% amino acid, 0.4% EDTA-Mg, 0.6% EDTA-Zn, 0.6% EDTA-Fe, 0.4% boric acid.

[0043] The preparation method is the same as in Example 1.

[0044] Application method is the same as embodiment 1.

Embodiment 3

[0046] Provide a special foliar fertilizer for yam, including the components: in terms of mass percentage, potassium dihydrogen phosphate is 23%, dipotassium hydrogen phosphate is 16.5%, potassium tripolyphosphate is 3%, urea is 34.5%, humic 13% acid, 8% amino acid, 0.7% EDTA-Mg, 0.5% EDTA-Zn, 0.5% EDTA-Fe, 0.3% boric acid.

[0047] The preparation method is the same as in Example 1.

[0048] Application method is the same as embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com