Paper flame retardant with high film-forming property and preparation method thereof

A technology of film-forming properties and flame retardants, which is applied in the field of flame retardants, can solve the problems of uneven distribution of flame retardants, poor film-forming properties, and easy aging, so as to achieve enhanced mechanical properties, enhanced coating effects, The effect of not easy to break

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] The present embodiment provides the preparation of the modified vinyl acetate copolymer emulsion of the present invention, specifically:

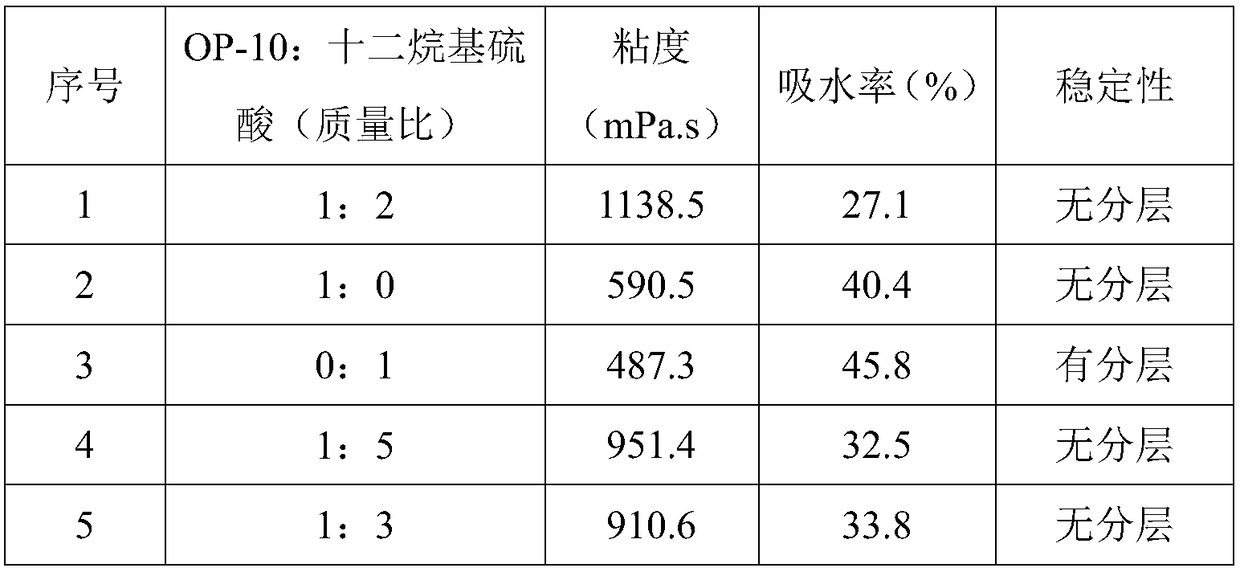

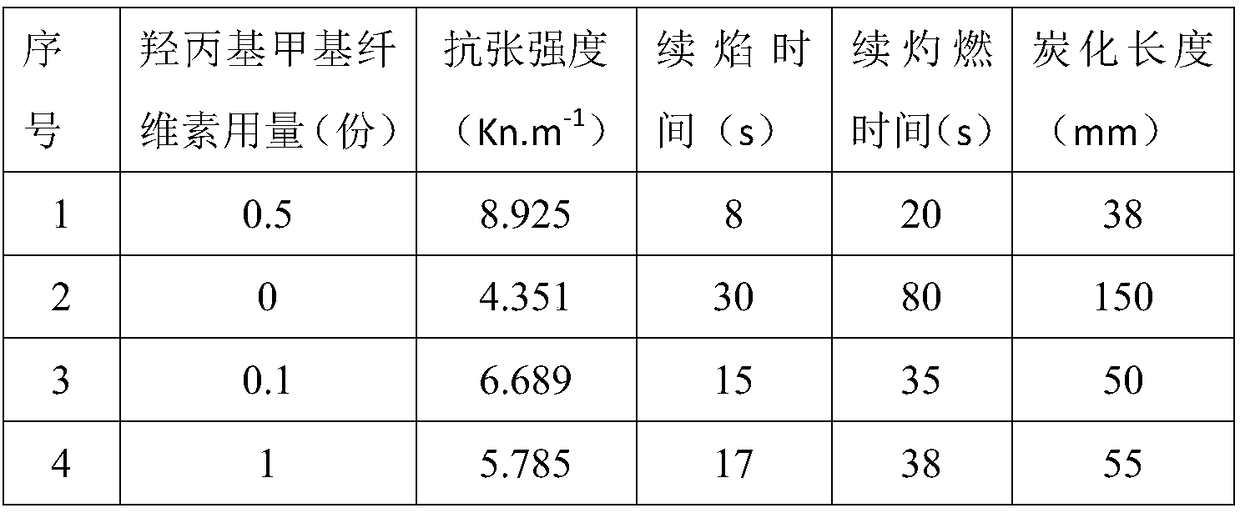

[0038] Step A. Prepare the components by weight: 200 parts of vinyl acetate, 60 parts of butyl acrylate, 2 parts of polyvinyl alcohol, 3 parts of nano silicon dioxide, 0.5 part of hydroxypropyl methylcellulose, 400 parts of water , OP-10 and sodium lauryl sulfate (mass ratio 1:2) 2 parts, potassium persulfate 2 parts.

[0039] Step B. adding water to potassium persulfate to make a concentration of 5wt% initiator solution;

[0040] Step C. Add 10 times the amount of water to hydroxypropyl methylcellulose and ultrasonically disperse evenly, then add nano-silica to continue ultrasonically dispersing to obtain liquid A;

[0041] Step D. Take polyvinyl alcohol, add the remaining water, raise the temperature, after the polyvinyl alcohol is completely dissolved, cool down to 50-60°C, add emulsifier, vinyl acetate and butyl acrylate, emulsi...

Embodiment 2

[0043] This example provides the preparation of the modified vinyl acetate copolymer emulsion of the present invention. Compared with Example 1, only the raw material composition is different, and the rest of the conditions are the same.

[0044] The raw material composition of this embodiment is: 300 parts of vinyl acetate, 50 parts of butyl acrylate, 3 parts of polyvinyl alcohol, 1 part of nano silicon dioxide, 1 part of hydroxypropyl methylcellulose, 400 parts of water, dodecane 3 parts of sodium base sulfate, 1 part of potassium persulfate.

Embodiment 3

[0046] This example provides the preparation of the modified vinyl acetate copolymer emulsion of the present invention. Compared with Example 1, only the raw material composition is different, and the rest of the conditions are the same.

[0047] The raw material composition of this embodiment is: 100 parts of vinyl acetate, 80 parts of butyl acrylate, 1 part of polyvinyl alcohol, 5 parts of nano silicon dioxide, 0.1 part of hydroxypropyl methylcellulose, 1000 parts of water, OP-10 1 part, potassium persulfate 3 parts.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com