Extrusion steel semi-grouting sleeve and preparation method thereof

A semi-grouting sleeve and sleeve technology, applied in the direction of structural elements, building components, building reinforcements, etc., can solve the problems of easy formation of sharp corners, low elongation, low production efficiency, etc. Controllable process and fast production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

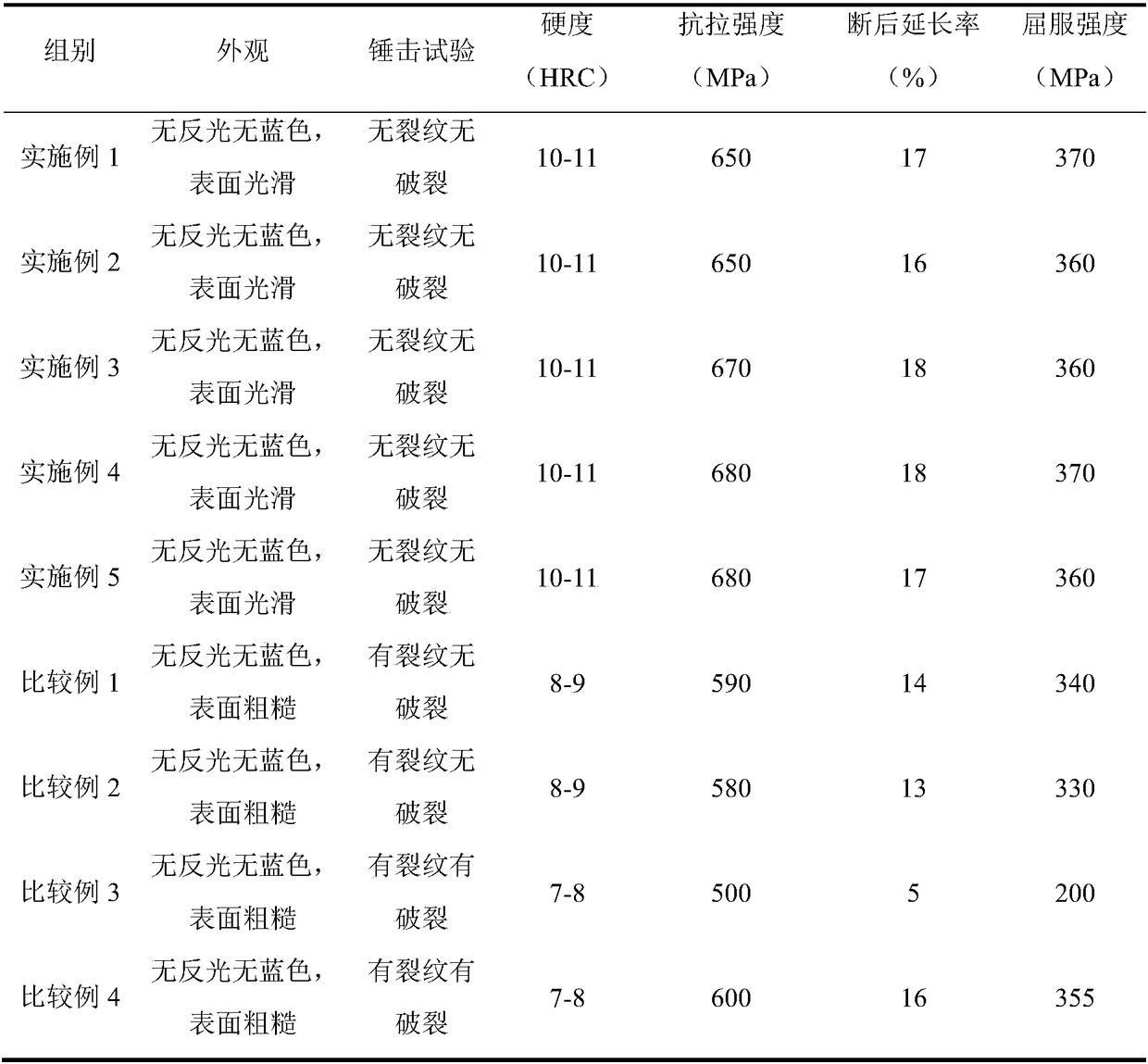

Examples

Embodiment 1

[0038] A kind of preparation method of semi-grouting sleeve comprises the steps:

[0039] 1) Raw material steel bar inspection, the material of the steel bar is No. 45 steel;

[0040] 2) Cutting;

[0041] 3) thermal perforation;

[0042] 4) Removal of oxide skin phosphorus saponification: immerse the sleeve capillary tube treated in the above steps into a pickling solution tank with a concentration of 20% and a pH≤2 for 25 minutes; drain the pickled capillary tube and immerse it in the In the first cleaning tank, lift it up and down repeatedly for 2-3 times to clean the remaining acid; then immerse it in the second cleaning tank, then lift it up and down for 2-3 times for cleaning; then clean it After draining the capillary of the sleeve, immerse in the phosphating solution pH = 2, and phosphating in the phosphating solution tank at a temperature of 75°C for 20 minutes; then drain the capillary of the phosphating sleeve and immerse it in the third cleaning tank, and then lif...

Embodiment 2

[0049] A kind of preparation method of semi-grouting sleeve comprises the steps:

[0050] 1) Raw material steel bar inspection, the material of the steel bar is No. 45 steel, and the elongation rate of the steel material is 18%;

[0051] 2) Cutting;

[0052] 3) thermal perforation;

[0053] 4) Removal of oxide skin phosphorus saponification: immerse the sleeve capillary tube treated in the above steps into a pickling solution tank with a concentration of 20% and a pH≤2 for 25 minutes; drain the pickled capillary tube and immerse it in the In the first cleaning tank, lift it up and down repeatedly for 2-3 times to clean the remaining acid; then immerse it in the second cleaning tank, then lift it up and down for 2-3 times for cleaning; then clean it After draining the capillary of the sleeve, immerse in the phosphating solution pH = 2, and phosphating in the phosphating solution tank at a temperature of 75°C for 20 minutes; then drain the capillary of the phosphating sleeve a...

Embodiment 3

[0060] Concrete operation steps are basically consistent with embodiment 2, just difference is:

[0061] 6) One-time annealing treatment: place the cold-rolled capillary sleeve in a continuous annealing furnace for continuous annealing treatment, set 7 nozzles on the continuous annealing furnace, set the air volume of the continuous annealing furnace to be large, and set the annealing temperature to 710 ℃, the heating rate of the primary annealing is 8.5℃ / min, the annealing time is 28min, and the related properties of the treated sleeve and capillary are tested;

[0062] 7) Squeeze the compression pipe after cutting. The grouting sleeve mold is composed of 8 petals. The extrusion length can reach 200mm, and the extrusion diameter can be reduced by 15mm. It is under pressure in all directions and has relatively high toughness requirements for steel materials;

[0063] 8) Secondary annealing treatment: place the cold-rolled sleeve capillary in a continuous annealing furnace for ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

| Yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com