A preparation method of porous nitrogen-doped carbon material based on fungal biomass and application thereof

A nitrogen-doped carbon and biomass technology, applied in carbon preparation/purification, hybrid/electric double-layer capacitor manufacturing, hybrid capacitor electrodes, etc., can solve the problem of uncontrollable doping ratio, etc. , excellent electrochemical performance, the effect of increased conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

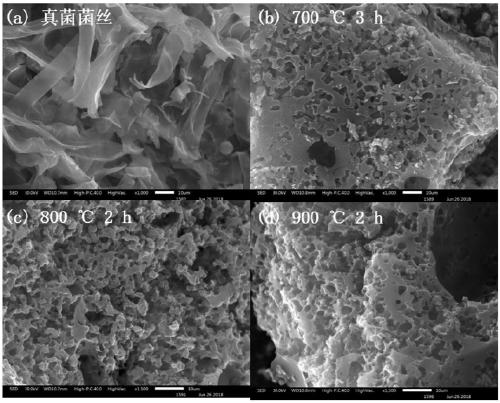

[0037] (1) Collect the fungal cells that accumulate oil, and inoculate C. chinensis, which was purchased from the China General Microbial Culture Collection and Management Center, in a sterile fermentation medium with glucose as the sole carbon source and cultivate for 20 hours, and filter and separate. , the microbial cells obtained by filtration are washed 3 times with deionized water and freeze-dried to obtain oil-producing fungal cells that accumulate grease,

[0038] Described bacterial fermentation medium is glucose 80g / L, (NH 4 ) 2 SO 4 3g / L, MgSO 4 ·7H 2 O 3g / L, KH 2 PO 4 1g / L.

[0039] (2) take by weighing 1g the fungal thalline and urea of accumulating grease collected through step 1 and add in potassium hydroxide solution to obtain mixed solution, wherein the fungal thalline of accumulating grease: potassium hydroxide: urea is 1:1:1, After soaking and activation for 1 h, the mixture was freeze-dried in vacuum to obtain a dry product.

[0040] (3) Put the dr...

Embodiment 2

[0045] (1) Collect the fungal cells that accumulate grease, and inoculate the C. chinensis, which was purchased from the China General Microbial Culture Collection and Management Center, in a sterile fermentation medium with glucose as the sole carbon source and cultivate for 22 hours, and filter and separate. , the microbial cells obtained by filtration are washed 3 times with deionized water and freeze-dried to obtain oil-producing fungal cells that accumulate grease,

[0046] Described bacterial fermentation medium is glucose 80g / L, (NH 4 ) 2 SO 4 3g / L, MgSO 4 ·7H 2 O 3g / L, KH 2 PO 4 1g / L.

[0047] (2) take by weighing the fungal thalline of the accumulated grease collected by step 1, urea adds in the potassium hydroxide solution to obtain a mixed solution, and wherein the fungal thalline of accumulated grease: potassium hydroxide: urea is 1:1.5:1.5, After soaking and activation for 1 h, the mixture was freeze-dried in vacuum to obtain a dry product.

[0048] (3) P...

Embodiment 3

[0053] (1) Collect the fungal cells of accumulating oil, collect the fungal cells that accumulate oil, and inoculate the fungal cells of C. chinensis purchased from the China General Microbial Culture Collection and Management Center in a sterile fermentation with glucose as the only carbon source Cultivated in the medium for 24h, filtered and separated, washed the filtered cells 3 times with deionized water, and freeze-dried to obtain oil-producing fungal cells that accumulated oil.

[0054] Described bacterial fermentation medium is glucose 80g / L, (NH 4 ) 2 SO 4 3g / L, MgSO 4 ·7H 2 O 3g / L, KH 2 PO 4 1g / L.

[0055] (2) take by weighing the fungal thalline of 1g accumulating oil and fat collected through step 1, urea is added in potassium hydroxide solution to obtain mixed solution, wherein the fungal thalline of accumulating oil and fat: potassium hydroxide: urea is 1:1:1, soaking After activation for 1 h, the mixture was freeze-dried in vacuo to obtain a dry product. ...

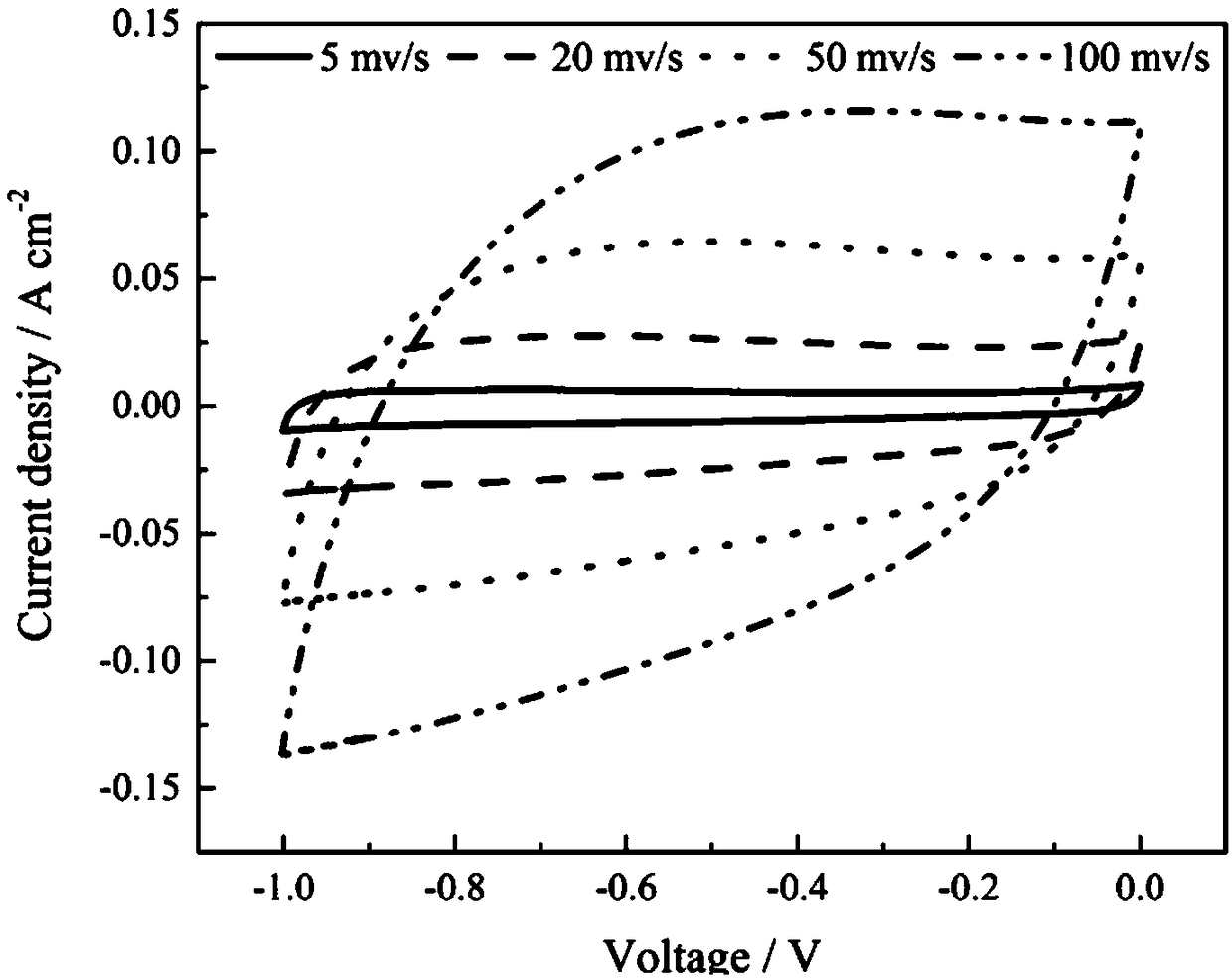

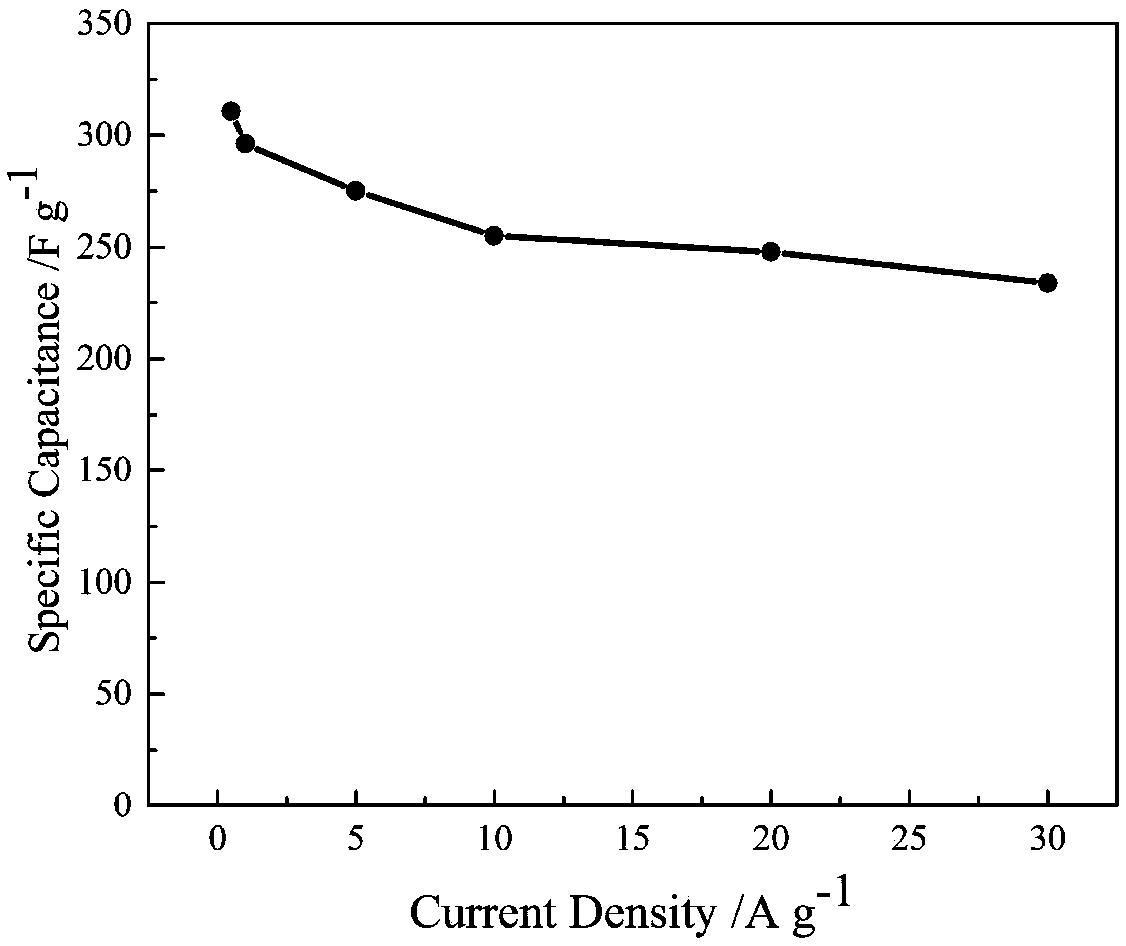

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific capacitance value | aaaaa | aaaaa |

| Specific capacitance value | aaaaa | aaaaa |

| Specific capacitance value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com