Microsphere preparation device and method thereof

A technology of microspheres and heating equipment, applied in the field of microspheres, can solve the problems of complex process, low output and long time, and achieve the effects of good safety, high output and controllable size of microspheres

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0067] The device for preparing microspheres provided in this example is as figure 1 shown, including:

[0068] Cylindrical barrel of polyethylene with a diameter of 11.5 mm and a length of 74 mm;

[0069] The moving slide rail 3 arranged inside the syringe, the moving slide rail 3 is a threaded piston rod, the stroke of the moving slide rail is 20cm, the pitch of the thread is 3mm, the moving slide rail can Form a closed cavity with the syringe, modify the volume of the cavity by changing the position of the moving slide rail, and form a gas pressure during the change of the cavity volume, so as to realize the suction of liquid from the outside into the syringe and squeeze the liquid out of the syringe The function is similar to the booster of the syringe;

[0070] The motor arranged at the tail of the moving slide rail 3, the motor is connected with the tail of the moving slide rail through a mechanical mechanism (coupling) and / or an electric circuit, and can push the movi...

Embodiment 2

[0081] The preparation of embodiment 2PLGA microspheres

[0082] Adopt the device described in embodiment 1 to prepare microspheres:

[0083] Before preparing the microspheres, the needle was inserted into the electric heating rod to heat, and the heating temperature of the electric heating rod was controlled by the temperature controller to reach 60°C. After the heating was completed, the needle and the sleeve were assembled to form a nozzle and installed on the gas distribution row.

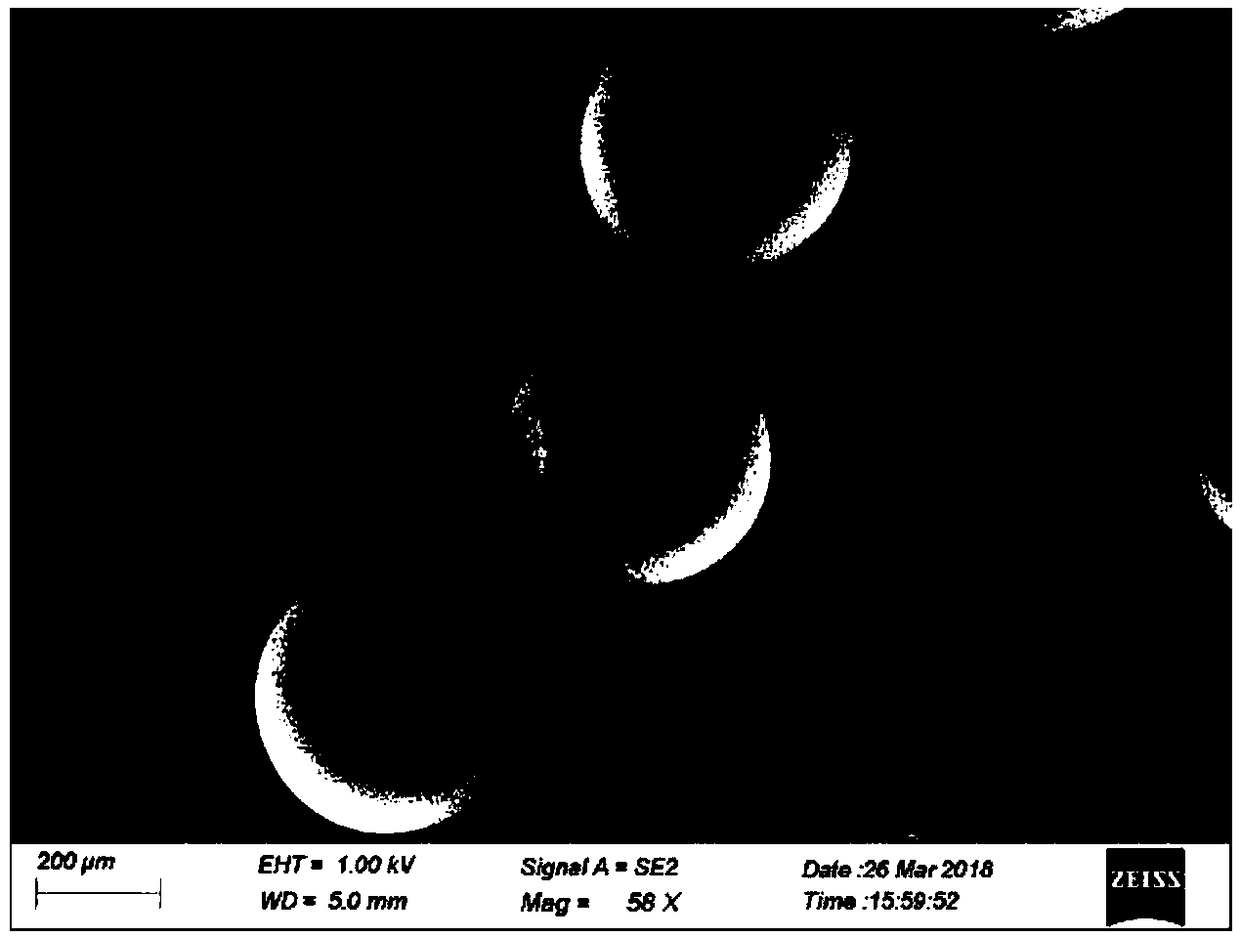

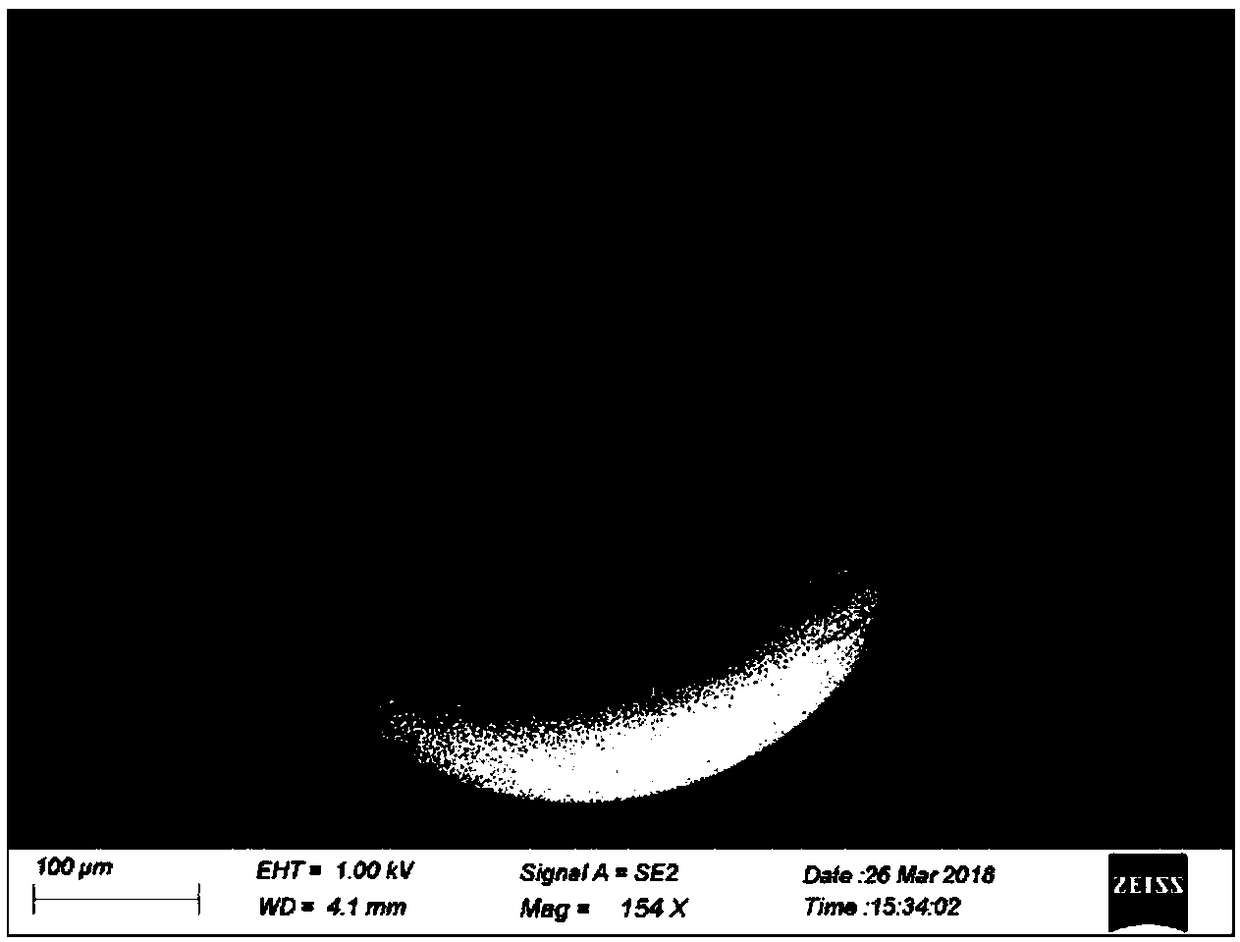

[0084] The NMP (N-methylpyrrolidone) solution of PLGA with a mass concentration of 15% is packed into the syringe, the stepper motor controller is set to control the motor to rotate and the moving slide rail is moved, so that the speed of the moving slide rail advancing the solution is 0.2mL / min enters the needle of the nozzle through the air distribution exhaust, and the gas in the nitrogen cylinder enters the air flow channel of the nozzle through the air distribution exhaust at a speed of 1...

Embodiment 3

[0086] The preparation of embodiment 3 chitosan microspheres

[0087] Adopt the device described in embodiment 1 to prepare microspheres:

[0088] Before preparing microspheres, insert the needle into the electric heating rod for heating, and control the heating temperature of the electric heating rod to reach 60°C through the temperature controller. After the heating is completed, assemble the needle and the sleeve to form a nozzle and install it on the gas distribution row.

[0089] Put the acetic acid solution of chitosan with a mass concentration of 5% into the syringe, set the stepper motor controller to control the motor to rotate to move the mobile slide rail, so that the speed of the mobile slide rail to push the solution is 0.3mL / min through the gas distribution exhaust Entering the needle of the nozzle, by controlling the flow meter and the pressure reducing valve, the gas in the nitrogen cylinder enters the gas channel in the nozzle through the gas distribution exha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com