Control method for membrane fouling and sludge yield of membrane bioreactor

A technology of membrane bioreactor and control method, which is applied in the field of control, membrane fouling and sludge yield control of membrane bioreactor, to achieve the effect of lasting effect, strengthening EPS and SMP degradation, slowing adhesion and inhibiting the formation of gel layer

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

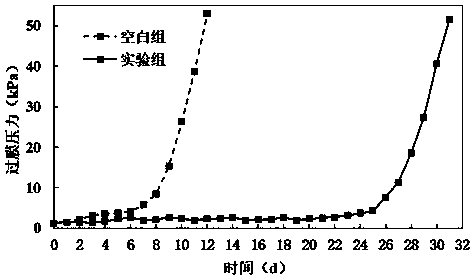

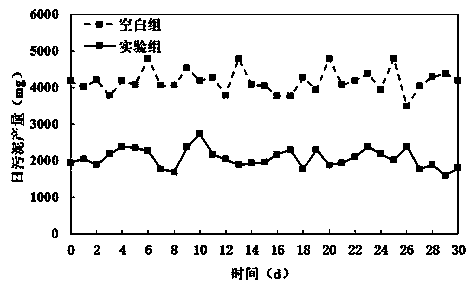

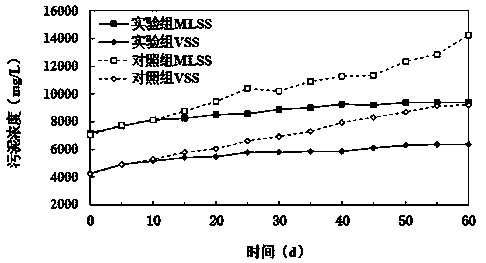

Examples

Embodiment 1

[0020] Embodiment 1: a kind of membrane bioreactor membrane fouling and sludge yield control method, described method comprises as follows specifically: 1) with Bdellovibrio class organism, xanthococcus, Stoop Bdellovibrio, Starr One or more of Bdellovibrio, yeast, bacillus, and actinomycetes to prepare multifunctional composite bacterial agents;

[0021] 2) Feed the multifunctional composite microbial agent into the membrane bioreactor after direct or on-site activation.

[0022] The concentration range of microorganisms in the multifunctional composite bacterial agent in the step 1) is within 10 6 —10 13 pfu / mL.

[0023] The dosage of the multifunctional composite bacterial agent in the step 2) is 0.05-0.5‰ of the treated water in the membrane bioreactor.

[0024] The dosing frequency of the multifunctional composite bacterial agent in the step 2) is 2-10 days.

[0025] The membrane bioreactor in step 2) is an aerobic-membrane reactor, and the dosing point is set at the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com