Special additive for bare concrete

A technology of fair-faced concrete and admixtures, applied in the field of concrete admixtures, which can solve problems such as greater impact on concrete fluidity and strength, less impact on concrete fluidity, and reduced compressive and flexural strength, so as to reduce the phenomenon of bottom sinking and bleeding , enhance the effect of water reduction, improve the effect of early strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

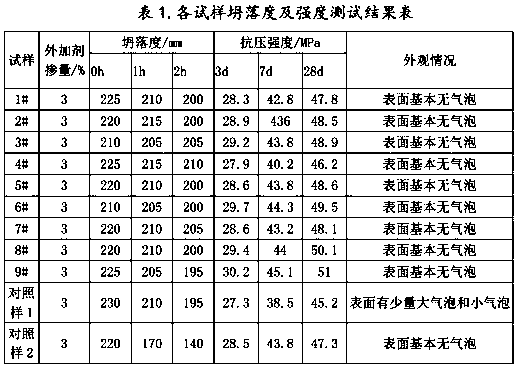

Examples

Embodiment 1

[0031] A special admixture for fair-faced concrete, the components are as follows by mass percentage: 20% water reducer, 1.8% retarder, 0.03% alkylsulfonate, 8% sodium nitrite, 1.5% hydroxypropyl cellulose , polysiloxane 0.04%, and the balance is water. Among them, the water reducer is prepared from amino water reducer and calcium lignosulfonate according to the mass ratio of 6:4; the alkyl sulfonate is sodium alkyl sulfonate; the retarder is sodium gluconate and white sugar The mixture, and the mass ratio of sodium gluconate and white sugar is 3:1.

Embodiment 2

[0033] A special admixture for fair-faced concrete. The components are as follows by mass percentage: 21% water reducer, 1.9% retarder, 0.04% alkylsulfonate, 8.5% sodium nitrite, 1.52% hydroxymethyl cellulose , polysiloxane 0.05%, and the balance is water. Among them, the water reducer is prepared from amino water reducer and calcium lignosulfonate according to the mass ratio of 6:4; the alkyl sulfonate is sodium alkyl sulfonate; the retarder is sodium gluconate and white sugar The mixture, and the mass ratio of sodium gluconate and white sugar is 3:1.

Embodiment 3

[0035] A special admixture for fair-faced concrete. The components are as follows by mass percentage: 22% water reducer, 2% retarder, 0.05% alkylsulfonate, 9.0% sodium nitrite, and 0.8% hydroxypropyl cellulose , hydroxymethyl cellulose 0.8%, polysiloxane 0.08%, and the balance is water. Among them, the water reducer is prepared from amino water reducer and calcium lignosulfonate according to the mass ratio of 6:4; the alkyl sulfonate is sodium alkyl sulfonate; the retarder is sodium gluconate and white sugar The mixture, and the mass ratio of sodium gluconate and white sugar is 3:1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com