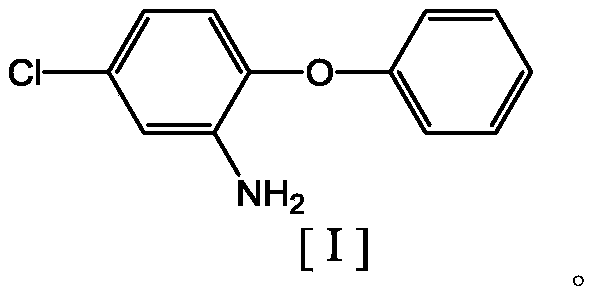

Synthesis method of 5-chlorine-2-phenoxyaniline and Beta molecular sieve used in synthesis method

A technology of phenoxyaniline and synthesis method, which is applied in the direction of molecular sieve catalysts, preparation of amino compounds, chemical instruments and methods, etc., can solve problems such as high reaction temperature and complex design of rectification tower, so as to achieve no waste generation and energy saving Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0050] The preparation of example 1, a kind of Beta molecular sieve reduction catalyst, carries out following steps successively:

[0051] The following parts refer to parts by mass.

[0052] ①, 2.05 parts of NaAlO 2 (content in Al 2 o 3 ≥ 41.0%), 0.5 parts of NaOH (≥ 98%), 20.4 parts of water and 14.7 parts of tetraethylammonium hydroxide aqueous solution (tetraethylammonium hydroxide mass concentration is 25%) mixed, after stirring at 20 ° C for 20min, Add 22.5 parts of silica gel therein, and continue stirring for 30 minutes to obtain a gel mixture.

[0053] Silica gel can be selected from the chromatography silica gel H (200-300 mesh) of Qingdao Ocean Chemical Co., Ltd.

[0054] Move the gel mixture into a stainless steel synthesis kettle and seal it. After crystallization at 80°C for 10h, raise the temperature to 130°C, crystallize for 20h, cool to room temperature, wash 10 parts with deionized water, filter out water, and dry at 130°C 4h, and then calcined in a muff...

Embodiment 1

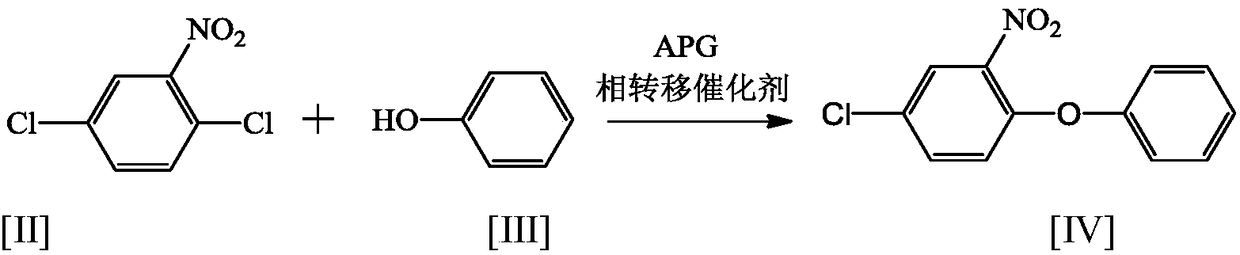

[0058] Embodiment 1, a kind of preparation method of 5-chloro-2-phenoxyaniline, carries out following steps successively:

[0059]

[0060] 1), 192.0g (1.0mol) 2,5-dichloronitrobenzene, heated up to 100°C, melted and stirred for 30 minutes, added 3.84g of condensation phase transfer catalyst APG, then alternately added 63g of sodium hydroxide and 103.0g of phenol (divided into 5 alternate additions), heated to 125°C after the addition, and kept stirring for 240 minutes;

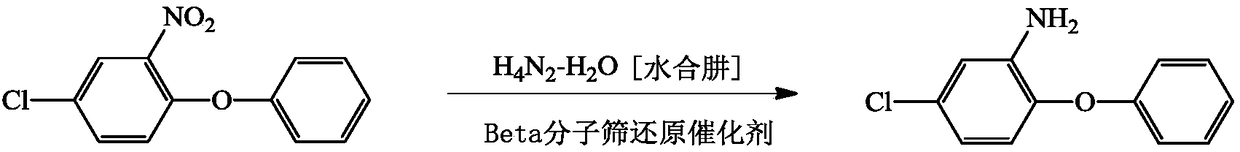

[0061] 2), the reaction product obtained in step 1) is cooled to 60°C, slowly add 400g water, 600g 80% (volume %) ethanol aqueous solution, add 95g 85% hydrazine hydrate (1.6mol), add 2.5g Beta molecular sieve reduction Catalyst, heated to reflux, reflux reaction for 220 minutes, reduction reaction to the end, cooling to 40 ° C, filtering out the Beta molecular sieve catalyst, adding 500 g of water to the filtrate, heating up to distill ethanol, when the distillation temperature rose to 96 ° C, stop heatin...

Embodiment 2

[0062] Embodiment 2, "600g80% (volume %) ethanol aqueous solution " in the replacement embodiment 1 of reclaiming ethanol (80%, volume %) 600g of embodiment 1 gained, all the other are equal to embodiment 1. Finally, 213.5 g (100%) of 5-chloro-2-phenoxyaniline was obtained, with a yield of 97.6% and a purity of 98%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com