Solar cell and its preparation method and photovoltaic module

A technology of solar cells and conditions, which is applied in the field of solar photovoltaics, and can solve problems such as insufficient improvement effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

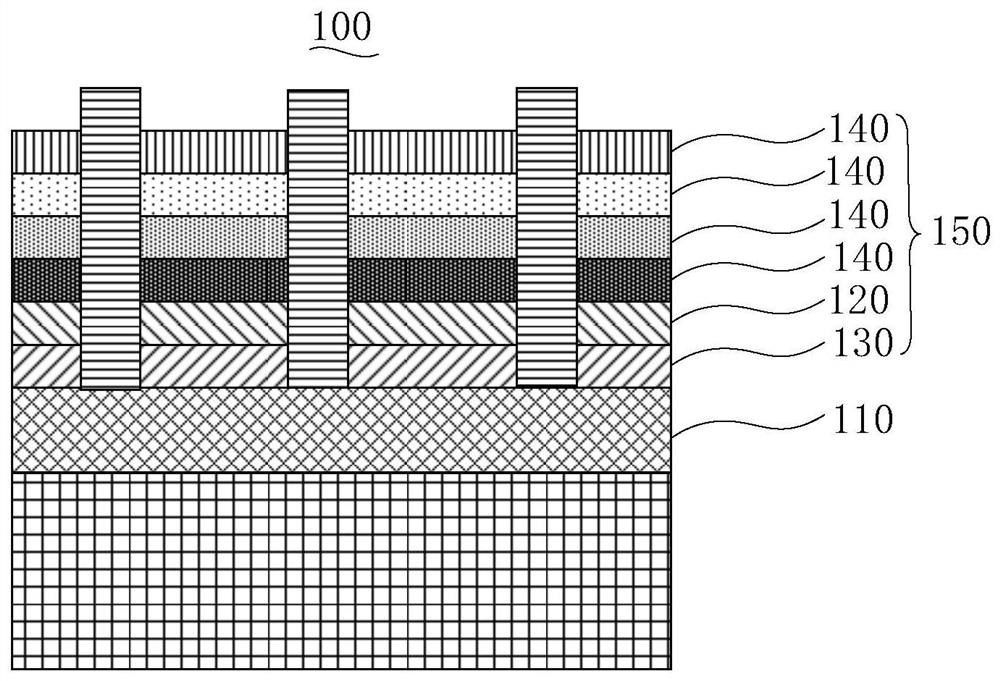

Image

Examples

preparation example Construction

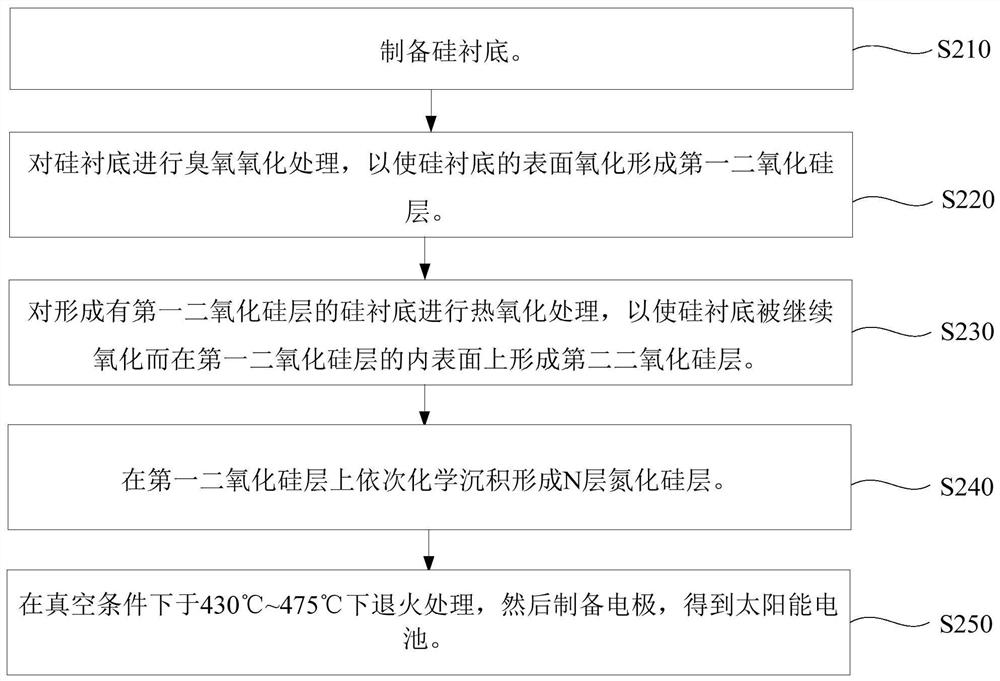

[0043] Such as figure 2 As shown, the method for preparing a solar cell according to an embodiment is a method for preparing the above-mentioned solar cell, and the method for preparing a solar cell includes the following steps:

[0044] Step S210: preparing a silicon substrate.

[0045] Specifically, the step of preparing a silicon substrate includes: cleaning the silicon wafer, and texturing on one surface of the silicon wafer to form a texturing surface, and then performing diffusion treatment on the texturing silicon wafer to form a PN junction, and then applying a PN junction to the silicon wafer Perform edge etching and remove the phosphorous silicate glass layer, and obtain a silicon substrate after cleaning. That is, the silicon substrate is a silicon wafer formed with a PN junction. Among them, the silicon wafer is monocrystalline silicon, polycrystalline silicon or quasicrystalline silicon. Specifically, the silicon substrate is a P-type silicon wafer.

[0046] Step S22...

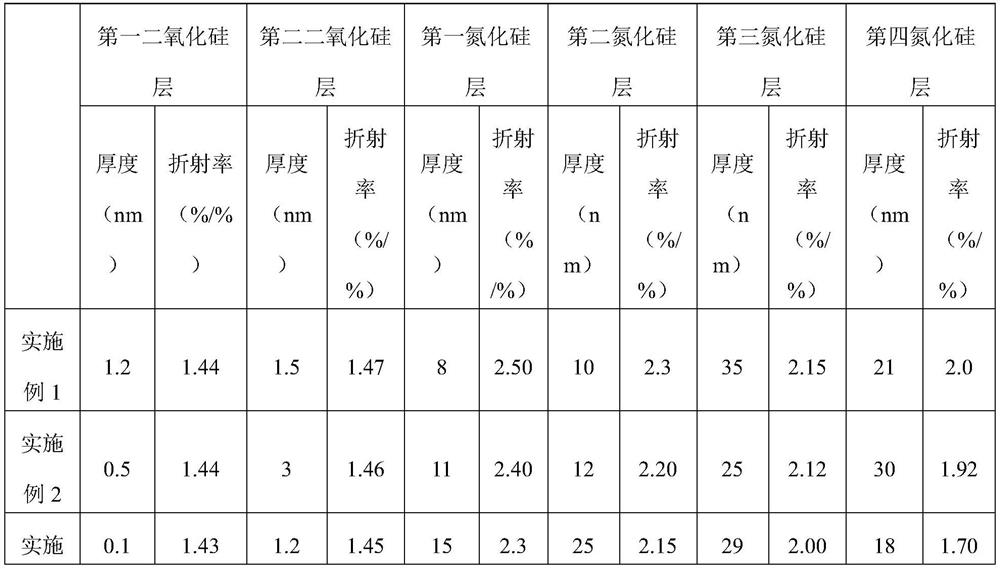

Embodiment 1

[0082] The preparation process of the solar cell of this embodiment is as follows:

[0083] (1) Use conventional hydrofluoric acid and nitric acid to add texturing additives to the original P-type polycrystalline silicon wafer that has been cut by diamond wire to form a suede surface by cleaning it once, and then diffuse the texturing silicon wafer to form a PN junction. After the edge is etched and the phosphosilicate glass is removed, it is cleaned to obtain a silicon substrate.

[0084] (2) Use an ozone generator to spray the silicon substrate through a spray plate for ozone oxidation treatment. The ozone concentration is 0.3ppm, the spray distance is 2 mm, and the temperature is 25°C to make the surface of the silicon substrate It can be oxidized to generate a first silicon dioxide layer with a refractive index of 1.44 and a thickness of 1.2 nanometers. Wherein, oxygen with a flow rate of 16 slm is passed through the ozone generator, and nitrogen with a flow rate of 15 slm is ...

Embodiment 2

[0096] The preparation process of the solar cell of this embodiment is as follows:

[0097] (1) Use conventional hydrofluoric acid and nitric acid to add texturing additives to the original P-type polycrystalline silicon wafer that has been cut by diamond wire to form a suede surface by cleaning it once, and then diffuse the texturing silicon wafer to form a PN junction. After the edge is etched and the phosphosilicate glass is removed, it is cleaned to obtain a silicon substrate.

[0098] (2) Use an ozone generator to spray the silicon substrate through a spray plate for ozone oxidation treatment. The ozone concentration is 0.1ppm, the spray distance is 1 mm, and the temperature is 20°C to make the surface of the silicon substrate It can be oxidized to generate a first silicon dioxide layer with a refractive index of 1.44 and a thickness of 0.5 nanometers. Wherein, oxygen at a flow rate of 1 slm is passed through the ozone generator, and nitrogen at a flow rate of 10 slm is passe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com