A preparation method of a platinum-based alloy catalyst

A technology of platinum-based alloys and catalysts, which is applied in the field of preparation of platinum-based alloy catalysts, can solve the problems of high price of precious metal platinum catalysts, achieve the effects of improving stability and durability, avoiding loss, and improving particle surface structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] The present embodiment provides the preparation method of platinum-nickel alloy catalyst, and it comprises the following steps:

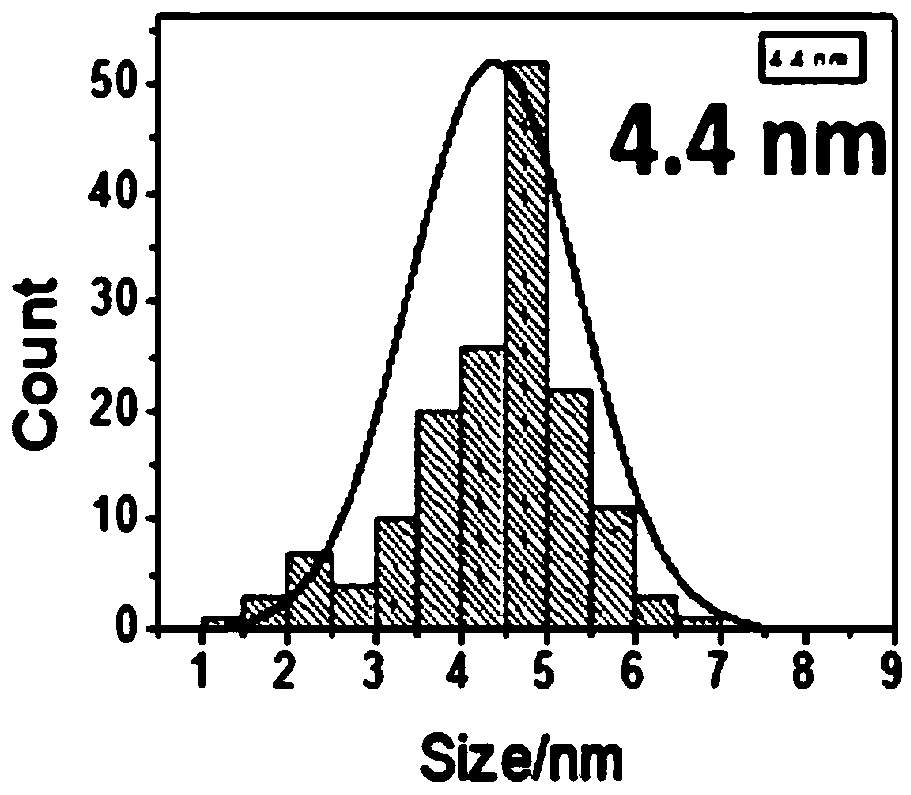

[0037] (1) Prepare platinum and nickel alloy particles with an average size of about 4.4nm, and control the atomic number ratio of platinum and nickel in the prepared alloy particles to be about 1: 3, such as figure 1 and 2 shown;

[0038] (2) at 70 degrees centigrade, adopt 0.5mol / L nitric acid aqueous solution to carry out acid treatment to the alloy particles prepared in step (1) for 6 hours;

[0039] (3) The alloy particles treated in step (2) are annealed in air at 180 degrees Celsius. The annealing time is 14 hours, and the platinum-nickel alloy catalyst is made, and the platinum-nickel alloy catalyst is measured. The average size of nickel alloy catalyst particles is about 4.1nm, and the atomic number ratio of platinum to nickel is about 3:1, such as image 3 and 4 shown.

[0040] Performance Testing

[0041] Sampling was carried...

Embodiment 2

[0045] The present embodiment provides the preparation method of platinum-cobalt alloy catalyst, and it comprises the following steps:

[0046] (1) Prepare platinum and cobalt alloy particles with an average size of about 2.5nm, and control the atomic number ratio of platinum and cobalt in the prepared alloy particles to be about 1: 3, such as Figure 5 shown;

[0047] (2) At 80 degrees centigrade, the alloy particles prepared in step (1) were acid-treated for 6 hours using a 0.5mol / L sulfuric acid aqueous solution;

[0048] (3) The alloy particles treated in step (2) are annealed in the air at 180 degrees Celsius for 14 hours to make the platinum-cobalt alloy catalyst, and the platinum-cobalt alloy catalyst is measured. The average size of cobalt alloy catalyst particles is about 2.3nm, and the atomic number ratio of platinum to cobalt is about 3:1, such as Figure 6 shown.

[0049] Performance Testing

[0050] Sampling was carried out, and the various performances of the c...

Embodiment 3

[0054] The present embodiment provides the preparation method of platinum iron alloy catalyst, and it comprises the following steps:

[0055] (1) Prepare platinum and iron alloy particles with an average size of about 3.1nm, and control the atomic number ratio of platinum and iron in the prepared alloy particles to about 1:3;

[0056] (2) At 60 degrees Celsius, the alloy particles prepared in step (1) were acid-treated for 4 hours by using 0.5mol / L acetic acid aqueous solution;

[0057] (3) The alloy particles treated in step (2) are annealed in air at 200 degrees Celsius for 12 hours, and the platinum-iron alloy catalyst is made, and the platinum-iron alloy catalyst obtained is measured. The average size of the catalyst particles is about 2.8 nm, and the atomic number ratio of platinum to iron is about 3:1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Average size | aaaaa | aaaaa |

| Average size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com