Summer laying hen feed and preparation method thereof

A technology for laying hen feed and preparation, which is applied in the field of summer laying hen feed and its preparation, can solve the problems of reduced egg weight, decreased egg production of hens, poor egg shell quality, etc., so as to reduce the blood sugar level and maintain a healthy state. , the effect of increasing egg production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

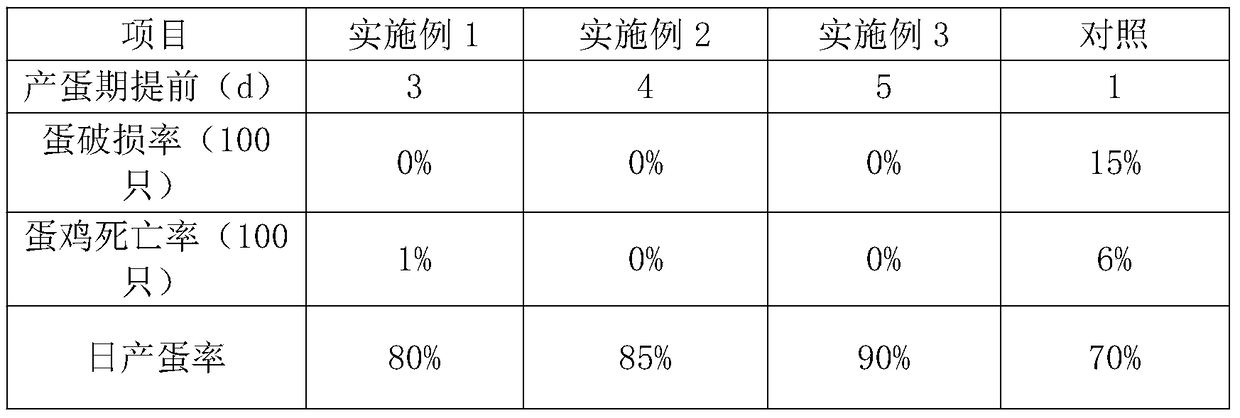

Examples

Embodiment 1

[0024] Raw materials (percentage by weight): 27.858% corn flour, 8% soybean meal, 10% cottonseed cake, 0.3% mixed powder (shell powder and stone powder are mixed at a mass ratio of 2:3), 20% Enzyme Enzyme, and 15% multivitamin , amino acid 10%, calcium 3.8%, phosphorus 0.39%, microbial ecological preparation 0.1%, natural garlic 1%, oil 1%, ammonium chloride 0.3%, fumaric acid 0.1%, aspirin 0.05%, bacitracin zinc 0.002% , flavoring agent 0.1%

[0025] (1) Preparation of Yineng Enzyme: crush corn, wheat, barley, and sorghum through a 50-mesh sieve, mix them evenly, air-dry them naturally for 7 days, store them in the warehouse for 20 days of aging, extract them with an ultrasonic pulverizer at 50°C for 30 minutes, and then add corn Mix DDGS evenly to get Yineng Enzyme;

[0026] (2) Soak the soybean meal, cottonseed cake, and natural garlic in water for 15 minutes, heat and boil for 30 minutes, and concentrate to a paste;

[0027] (3) In step (2), add corn flour, mixed flour, ...

Embodiment 2

[0031] Raw materials (percentage by weight): corn flour 15%, soybean meal 9%, cottonseed cake 10%, mixed powder 1% (shell powder and stone powder are mixed at a mass ratio of 1:2), billion energy enzyme enzyme 25%, multivitamins 20% , amino acid 10.428%, calcium 4%, phosphorus 0.42%, microbial ecological preparation 0.5%, natural garlic 2%, oil 2%, ammonium chloride 0.3%, fumaric acid 0.1%, aspirin 0.05%, bacitracin zinc 0.002% , flavoring agent 0.2%

[0032] (1) Preparation of Yineng Enzyme: crush corn, wheat, barley, and sorghum through a 60-mesh sieve, mix them evenly, air-dry them naturally for 6 days, store them in the warehouse for 25 days of aging, extract them with an ultrasonic pulverizer at 50°C for 20 minutes, and then add corn Mix DDGS evenly to get Yineng Enzyme;

[0033] (2) Soak soybean meal, cottonseed cake, and natural garlic in water for 157 minutes, heat and boil for 307 minutes, and concentrate to a paste;

[0034] (3) In step (2), add corn flour, mixed p...

Embodiment 3

[0038]Raw materials (percentage by weight): 22% corn flour, 8.558% soybean meal, 13% cottonseed cake, 1% mixed powder (shell powder and stone powder are mixed at a mass ratio of 2:3-4), 20% Enzyme Enzyme, multivitamins 15%, amino acid 10%, calcium 3.8%, phosphorus 0.39%, microbial ecological preparation 0.5%, natural garlic 2%, oil 3%, ammonium chloride 0.3%, fumaric acid 0.1%, aspirin 0.05%, bacitracin zinc 0.002%, flavoring agent 0.3%

[0039] (1) Preparation of Yineng Enzyme: crush corn, wheat, barley, and sorghum through an 80-mesh sieve, mix them evenly, air-dry them naturally for 7 days, store them in the warehouse for 30 days, and extract them with an ultrasonic pulverizer at 60°C for 15 minutes, then add corn Mix DDGS evenly to get Yineng Enzyme;

[0040] (2) Soak soybean meal, cottonseed cake, and natural garlic in water for 15-20 minutes, heat and boil for 30-45 minutes, and concentrate to a paste;

[0041] (3) In step (2), add corn flour, mixed powder, calcium, ph...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com