Low temperature synthesis method of kaliophilite catalyst used for preparation of biodiesel

A technology of biodiesel and kalephine, which is applied in the direction of physical/chemical process catalysts, chemical instruments and methods, biofuels, etc., can solve the problems of high energy consumption for preparation and no kalephine has been found, and achieve high catalytic activity and easy The effect of separation and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

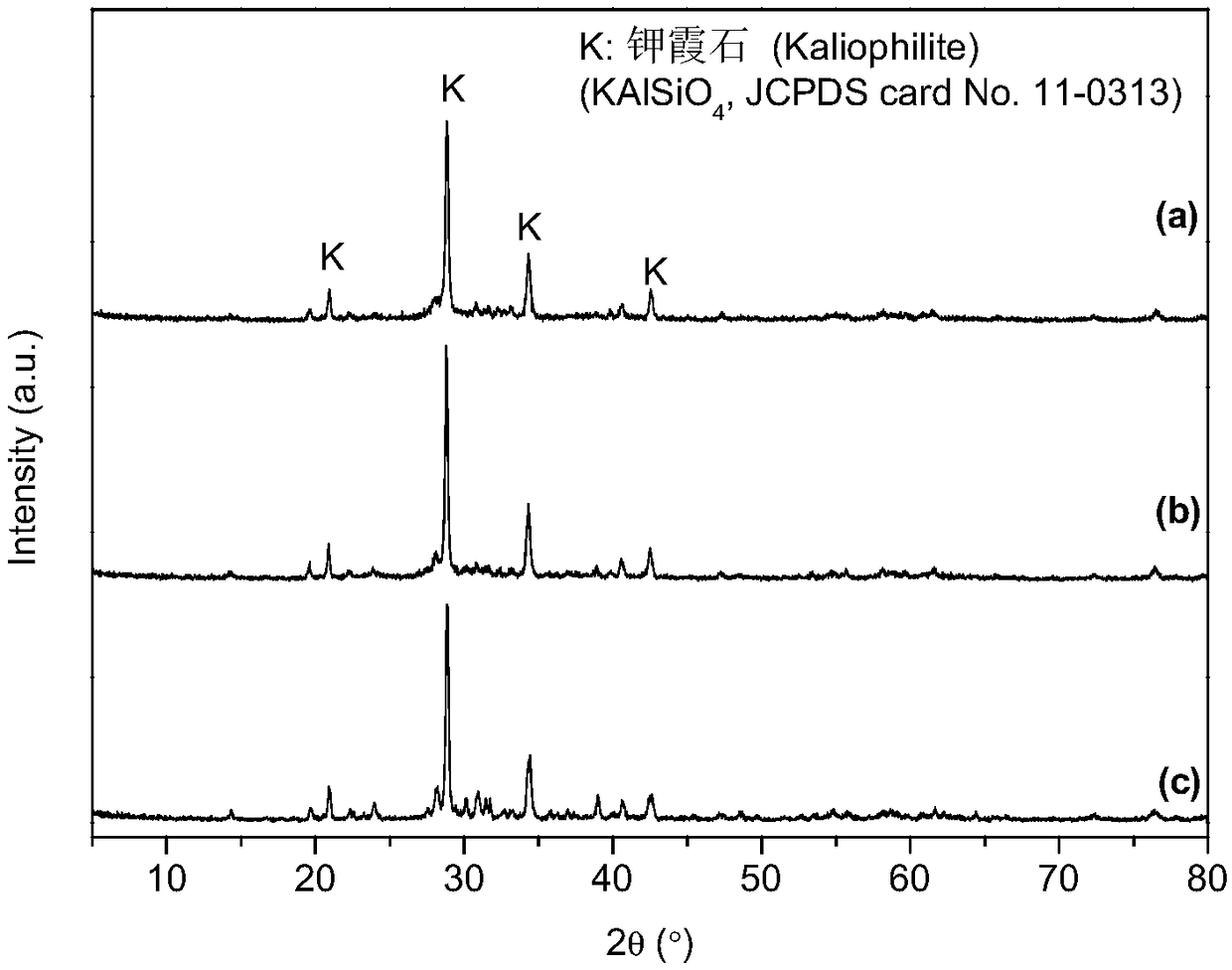

preparation Embodiment 1

[0050] (1) Take by weighing 100g circulating fluidized bed fly ash;

[0051] (2) Take by weighing 11.2g potassium hydroxide, put in the beaker;

[0052] (3) Take by weighing 65.6g potassium silicate, put in the beaker;

[0053] (4) the potassium hydroxide taken by step (2) is dissolved in the potassium water glass taken by step (3), stirred and cooled to room temperature;

[0054] (5) The mixed solution of step (4) is placed in a blender, the circulating fluidized bed fly ash taken in step (1) is placed in a blender, and stirred to obtain a uniform slurry;

[0055] (6) Pour the slurry into a mold to form it, vibrate to eliminate air bubbles, seal the mold with a plastic film sealing bag, place it in an incubator at 60°C for 24 hours, and then release the mold to obtain a bulk kanepheline precursor;

[0056] (7) Place the bulk kanepheline precursor obtained in step (6) in a 200mL hydrothermal reaction kettle, add 50mL of 4mol / L potassium hydroxide solution, seal the kettle, a...

preparation Embodiment 2

[0059] (1) Take by weighing 100g circulating fluidized bed fly ash;

[0060] (2) Take by weighing 11.2g potassium hydroxide, put in the beaker;

[0061] (3) Take by weighing 50.5g potassium silicate, put in the beaker;

[0062] (4) the potassium hydroxide taken by step (2) is dissolved in the potassium water glass taken by step (3), stirred and cooled to room temperature;

[0063] (5) The mixed solution of step (4) is placed in a blender, the circulating fluidized bed fly ash taken in step (1) is placed in a blender, and stirred to obtain a uniform slurry;

[0064] (6) Pour the slurry into a mold for molding, shake to eliminate air bubbles, seal the mold with a plastic film sealing bag, place it in an incubator at 80°C for 24 hours, and then release the mold to obtain a bulk kanepheline precursor;

[0065] (7) Put the bulk kanepheline precursor obtained in step (6) in a 200mL hydrothermal reaction kettle, add 50mL of 6mol / L potassium hydroxide solution, seal the kettle, and ...

preparation Embodiment 3

[0068] (1) Take by weighing 100g circulating fluidized bed fly ash;

[0069] (2) Take by weighing 11.2g potassium hydroxide, put in the beaker;

[0070] (3) Take by weighing 35.0g potassium silicate, put in the beaker;

[0071] (4) the potassium hydroxide taken by step (2) is dissolved in the potassium water glass taken by step (3), stirred and cooled to room temperature;

[0072] (5) The mixed solution of step (4) is placed in a blender, the circulating fluidized bed fly ash taken in step (1) is placed in a blender, and stirred to obtain a uniform slurry;

[0073] (6) Pour the slurry into a mold for molding, shake to eliminate air bubbles, seal the mold with a plastic film sealing bag, place it in an incubator at 80°C for 24 hours, and then release the mold to obtain a bulk kanepheline precursor;

[0074] (7) Place the bulk kanepheline precursor obtained in step (6) in a 200mL hydrothermal reaction kettle, add 50mL of 6mol / L potassium hydroxide solution, seal the kettle, an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com