Catalyst for flue gas denitration, and preparation method and application thereof

A denitrification catalyst and catalyst technology, applied in chemical instruments and methods, physical/chemical process catalysts, separation methods, etc., to achieve the effects of easy acquisition, simple preparation process, and low preparation cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

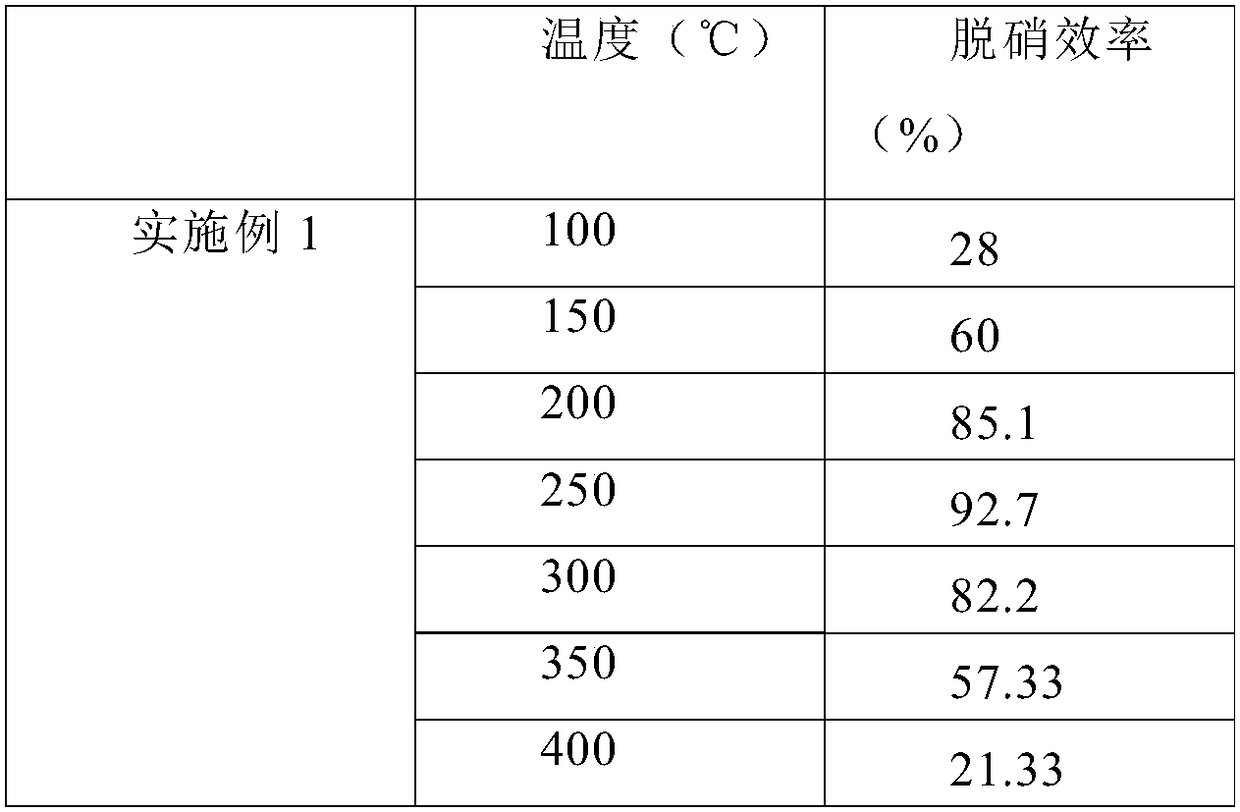

Embodiment 1

[0031] A Catalyst Fe-Eu / TiO for Flue Gas Denitrification 2 , according to the molar ratio of the contained active component and carrier is 0.15:1. The preparation method of the catalyst comprises the following steps:

[0032] (1) Dissolve 0.002 mol of europium nitrate, 0.015 mol of ferric nitrate, and 0.1 mol of sulfuric acid phthalein in deionized water, and stir at room temperature for 5-10 minutes; a mixed solution is obtained.

[0033] (2) Pour the ammonia water into the mixed solution until the pH value of the solution reaches 10 to form a precipitate, stir for 5-10 minutes and then let stand. The supernatant was decanted several times and fresh deionized water was added. until the PH value reaches 7;

[0034] (3) Filter the precipitate, dry it in an oven at 100°C for 24 hours, then move it to a muffle furnace, and calcinate it at 500°C for 4 hours to obtain black particles, which are denitration catalysts.

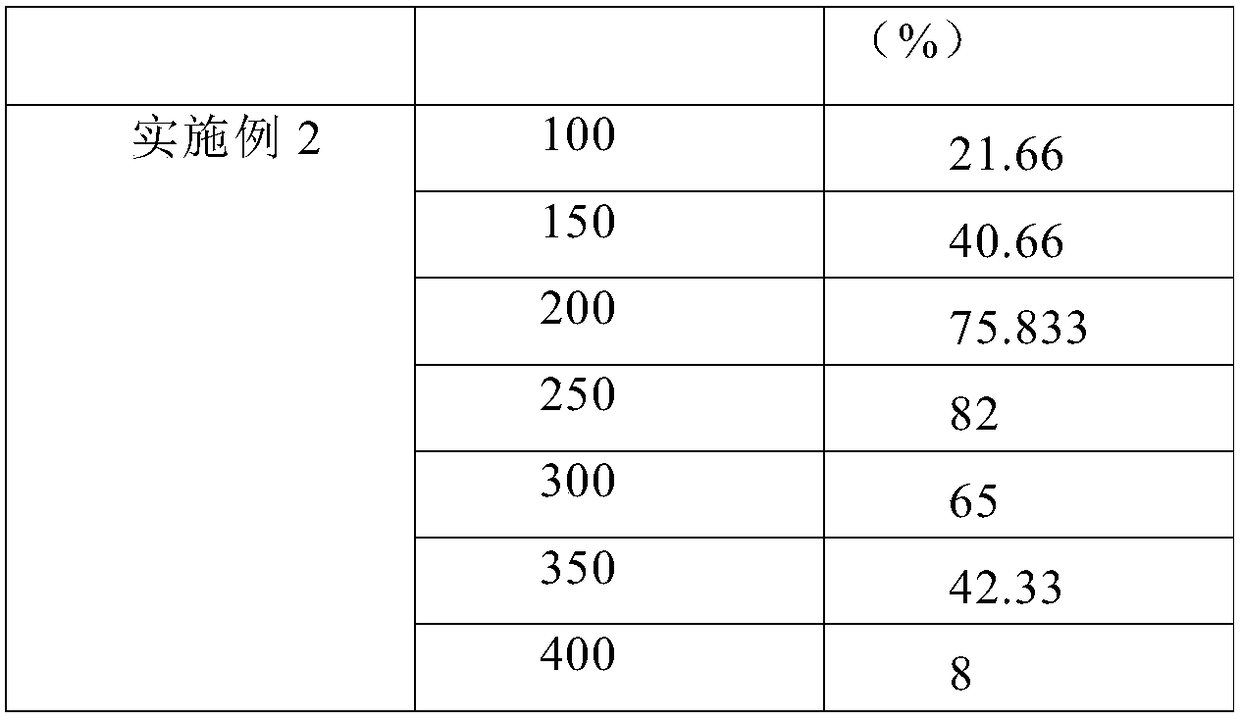

Embodiment 2

[0036] (1) Dissolve 0.1mol titanium sulfate and 0.015mol ferric nitrate in deionized water and stir for 5-10min to form a mixed solution;

[0037] (2) Pour the ammonia water into the mixed solution until the pH value of the solution reaches 10 to form a precipitate, stir for 5-10 minutes and then let stand. The supernatant was decanted several times and fresh deionized water was added. until the PH value reaches 7;

[0038] (3) Filter the precipitate, dry it in an oven at 100°C for 24 hours, then move it to a muffle furnace, and calcinate it at 500°C for 4 hours to obtain black particles, which are denitration catalysts.

Embodiment 3

[0040] A catalyst for flue gas denitrification, consisting of a carrier, an active component and an auxiliary agent, wherein the carrier used is titanium dioxide, the active component is iron oxide, the auxiliary agent is europium oxide, iron element, europium element, titanium The molar ratio of elements is 0.13:0.01:1.

[0041] The preparation method of the catalyst for flue gas denitrification adopts the following steps:

[0042] (1) Eu(NO 3 )3 ·6H 2 O, Fe(NO 3 ) 3 , Ti(SO 4 ) 2 Dissolve in deionized water according to the formula, and stir at room temperature to obtain a mixed solution;

[0043] (2) After pouring ammonia water into the mixed solution until the pH value of the solution reaches 10, a precipitate is formed, stirred and left standing, pouring off the supernatant liquid several times and adding new deionized water until the pH value reaches 7;

[0044] (3) Filter the precipitate, dry it in an oven at 100°C for 24 hours, and then move it to a muffle furna...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com