Creased titanium dioxide fiber loaded nanometer silver phosphate composite material and preparation method thereof

A technology of titanium dioxide and composite materials, applied in chemical instruments and methods, chemical/physical processes, physical/chemical process catalysts, etc., can solve the problems of poor load uniformity, complicated preparation methods, uncontrollable, etc., and achieve low cost and raw material sources Wide, load-maintaining effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

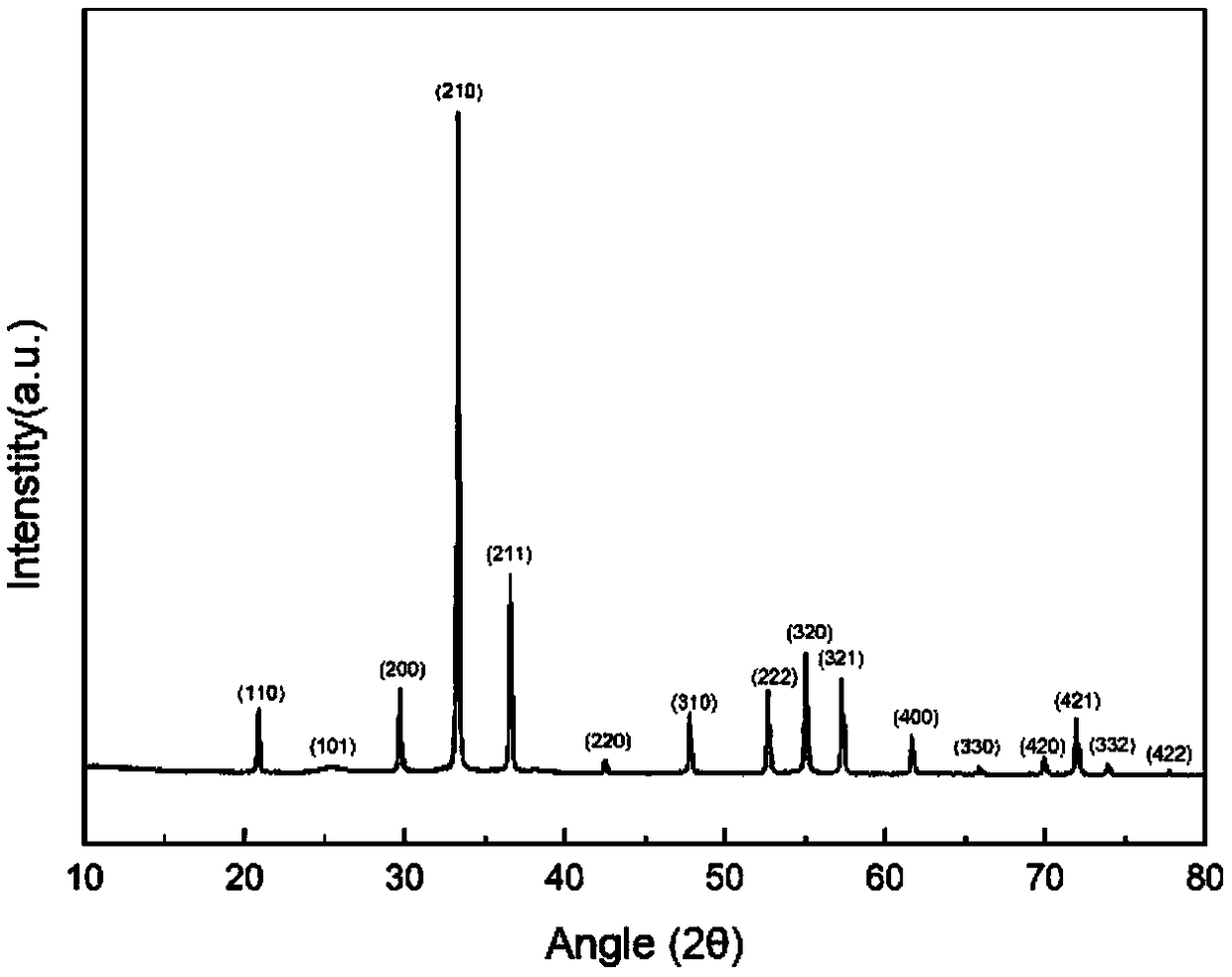

[0022] Take 150mg of TiO 2 Add fiber into 50mL deionized water, add 1.5mg of polyethylene glycol drop by drop, ultrasonicate for 30 minutes, weigh 913mg of silver nitrate and add to the above solution, stir for 6 hours to obtain solution A; weigh 254mg of disodium hydrogen phosphate Dissolve in deionized water and stir evenly to obtain a transparent solution B. Add solution B to solution A, then filter in the dark and stir for 12 hours, wash 2 times with ethanol, then wash 3 times with water, and dry the obtained product in an oven to obtain TiO 2 / Ag 3 PO 4 Composite fiber material. The XRD figure of gained composite material sees figure 1 , the obtained phase-pure TiO 2 / Ag 3 PO 4 composite material.

Embodiment 2

[0024] Take 150mg of TiO 2 Add fiber to 50mL deionized water, add 0.75mg of polyethylene glycol drop by drop, ultrasonicate for 30 minutes, weigh 36.5mg of silver nitrate and add it to the above solution, stir for 12 hours to obtain solution A; weigh 10.2mg of hydrogen phosphate Dissolve the disodium in deionized water and stir evenly to obtain a transparent solution B. Add solution B to solution A, then filter in the dark and stir for 24 hours, wash 3 times with ethanol, then wash 4 times with water, and dry the obtained product in an oven to obtain TiO 2 / Ag 3 PO 4 Composite fiber material. The SEM image of the obtained composite material is shown in figure 2 , to get TiO 2 / Ag 3 PO 4 Composite material, Ag 3 PO 4 Particles are uniformly loaded on TiO 2 surface of the fiber, Ag 3 PO 4 The particle size is about 10-20nm.

Embodiment 3

[0026] Take 150mg of TiO 2 Fiber, added to 50mL deionized water, 0.75mg polyethylene glycol was added dropwise, ultrasonicated for 30 minutes, 183mg silver nitrate was weighed and added to the above solution, stirred for 10 hours to obtain solution A; 50.8mg hydrogen phosphate dihydrogen phosphate was weighed Sodium was dissolved in deionized water and stirred evenly to obtain a transparent solution B. Add solution B to solution A, then filter in the dark and stir for 18 hours, wash with ethanol for 2 times, then wash with water for 4 times, and place the product in an oven to dry to obtain TiO 2 / Ag 3 PO 4 Composite fiber material.

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com