Optimized particle size ceramic reinforced metal matrix composite material and its preparation method and application

A composite material and metal-based technology, applied in the field of wear-resistant materials, can solve the problems of easy falling off, mechanical interface mechanical occlusion, falling off of the whole particle, etc., and achieve the effects of excellent mechanical properties, good interface connection and simple process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

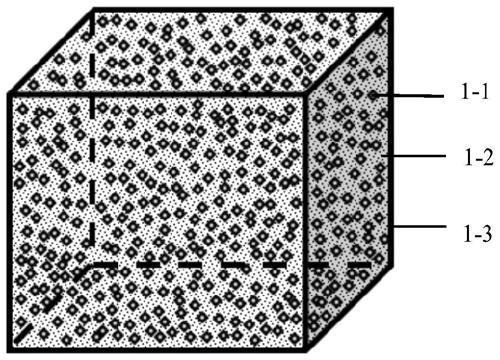

[0080] A ceramic reinforced metal matrix composite material with optimized particle size is used in the working area of the roller sleeve of the vertical mill. The roller sleeve of the vertical mill includes a tetragonal optimized particle size ceramic particle reinforced metal matrix composite material and casting material. The casting material is high-resistant Grinding alloy powder; the thickness of the working area is 1 / 3 of the height of the roller sleeve of the overall vertical mill;

[0081] The tetragonal-optimized ceramic particle-reinforced metal matrix composite material is obtained by sintering the tetragonal-compacted ceramic-reinforced block through programmed temperature-controlled liquid phase sintering;

[0082] The tetragonal compacted ceramic reinforced blocks include metal matrix materials and reinforced phase ceramic particles; wherein, the reinforced phase ceramic particles are 40% of the volume percentage of the tetragonal compacted ceramic reinforced b...

Embodiment 2

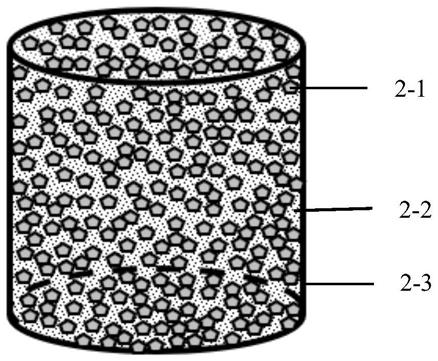

[0107] An optimized particle size ceramic reinforced metal matrix composite for use in the work zone of a vertical mill liner comprising a cylindrical optimized ceramic particle reinforced metal matrix composite and a casting material that is highly wear resistant Alloy powder; the thickness of the working area is 1 / 2 of the height of the liner of the overall vertical mill;

[0108] The cylinder-optimized ceramic particle-reinforced metal-matrix composite material is obtained by sintering a cylinder-compacted ceramic reinforcement block through programmed temperature-controlled liquid phase sintering;

[0109] The ceramic reinforced blocks compacted by cylinders include metal matrix materials and reinforced phase ceramic particles; wherein, the reinforced phase ceramic particles are 40% of the volume percentage of the cylindrically compacted ceramic reinforced blocks; the reinforced phase ceramic particles It is 1mm~5mm ceramic particles 2-1, 0.01μm~0.1μm ceramic particles and...

Embodiment 3

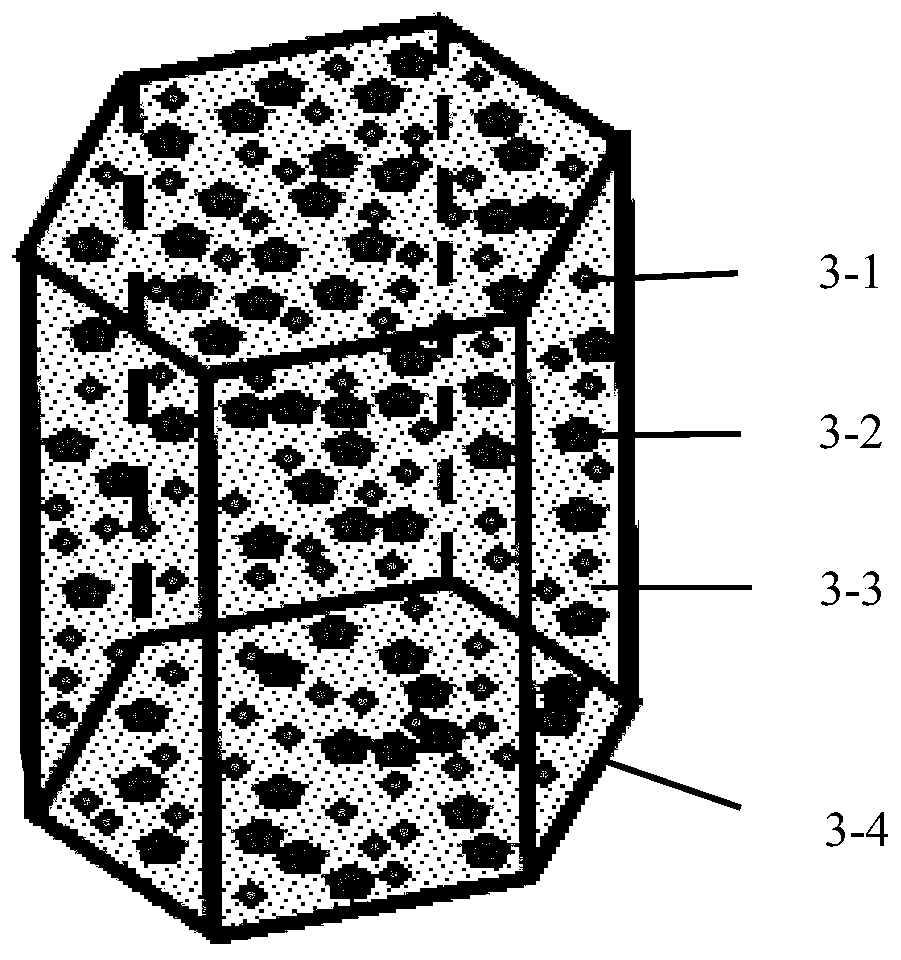

[0133] A ceramic reinforced metal matrix composite material with optimized particle size is used in the working area of the vertical mill roll cover. The vertical mill roll cover includes a hexagonal cylinder with optimized particle size ceramic particle reinforced metal matrix composite material and casting material. The casting material is High wear-resistant alloy powder; the thickness of the working area is 1 / 3 of the height of the roller sleeve of the overall vertical mill;

[0134] The hexagonal cylinder-optimized ceramic particle reinforced metal matrix composite material is obtained through programmed temperature-controlled liquid-phase sintering of a ceramic reinforcement block compacted by hexagonal cylinders;

[0135] The ceramic reinforced block compacted by hexagonal cylinders comprises a metal matrix material and ceramic particles of the reinforcing phase; wherein, the ceramic particles of the reinforced phase are 40% of the volume percentage of the ceramic rein...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com