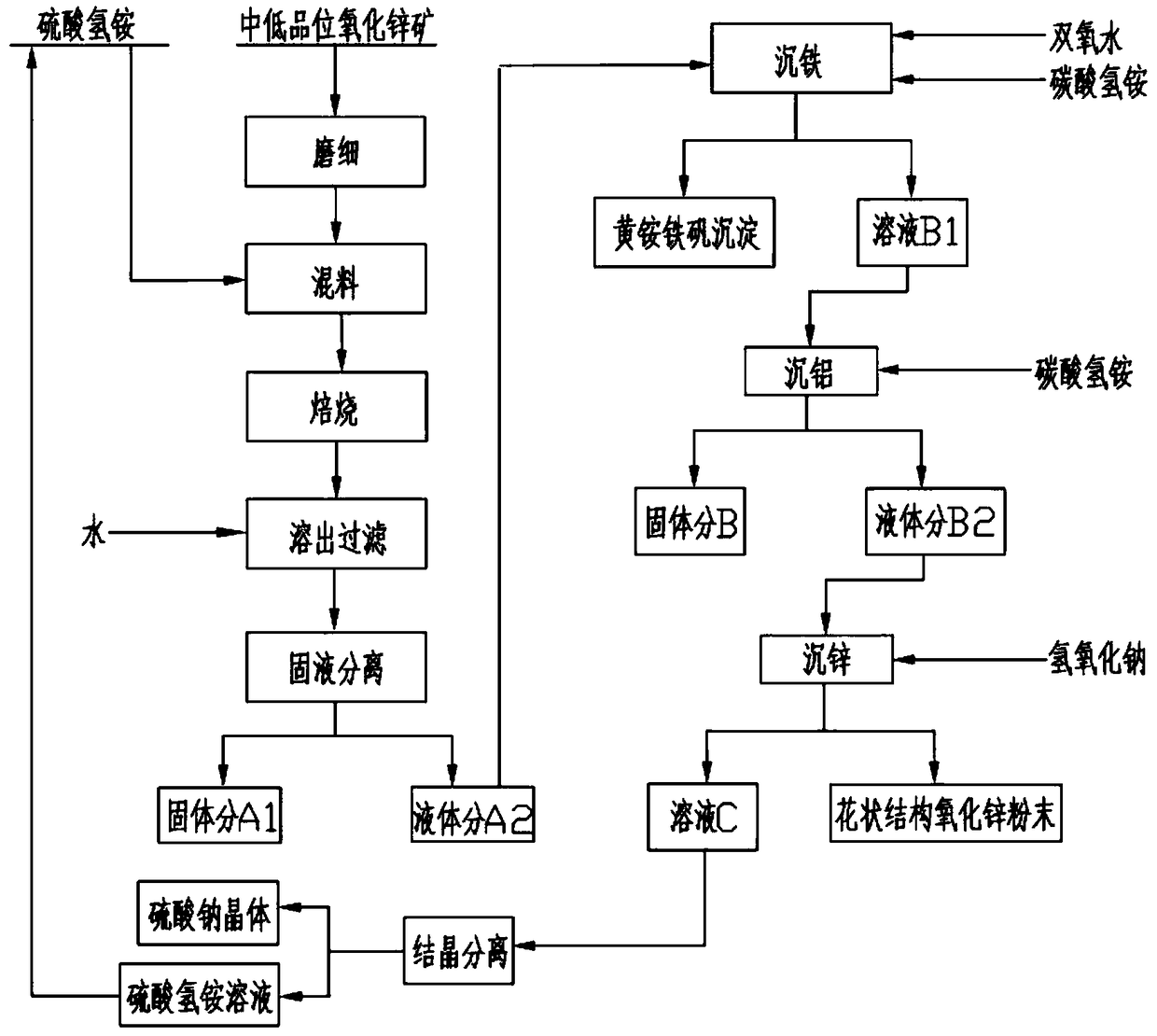

Method for preparing flower-like structure zinc oxide from low-and medium-grade zinc oxide ores

A technology of zinc oxide ore and flower-like structure is applied in the field of preparing flower-like structure zinc oxide powder, which can solve the problems of low product added value, many process links, low recovery rate, etc., and achieves good photocatalytic activity and broad application prospects. , the effect of high added value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0101] This embodiment is to limit the specific implementation conditions of steps S2 to S6 in the above general implementation scheme, and the rest of the undefined parts are carried out by referring to the steps of the above general scheme. in:

[0102] In step S2, the amount of ammonium bisulfate added is 1.2 times of the theoretical amount of ammonium bisulfate required for the complete reaction of zinc, iron and aluminum in the zinc oxide ore;

[0103] In step S3, the roasting temperature is 475°C, and the roasting time is 60 minutes;

[0104] In step S4, the amount of water added is 4 times the mass of the roasted product, and stirred and dissolved at 80° C. for 50 minutes;

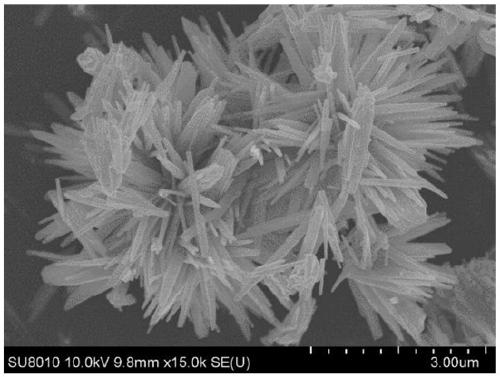

[0105] In step S5, during heavy iron treatment, add in the filtrate A1 and be used for oxidizing Fe 2+ hydrogen peroxide, and then slowly add ammonium bicarbonate, control the solution temperature to 95°C, control the solution pH to 1.5-2, react for 2.5 hours, adjust the solution pH to 3.8 after a...

Embodiment 2

[0108] This example is to limit the specific implementation conditions of steps S2 to S7 in the above overall implementation plan, and the rest of the undefined parts are carried out with reference to the steps of the above overall plan, wherein:

[0109] In step S2, the amount of ammonium bisulfate is 1.4 times the theoretical amount required to completely react the zinc, iron and aluminum in the zinc oxide ore;

[0110] In step S3, the calcination temperature is 450° C., and the calcination time is 90 minutes;

[0111] In step S4, the amount of water added is 4 times the mass of the roasted product, and stirred and dissolved at 80° C. for 60 minutes;

[0112] In step S5, during the heavy iron treatment, add to the filtrate A1 for oxidizing Fe 2+ hydrogen peroxide, and then slowly add ammonium bicarbonate, control the solution temperature to 95°C, control the solution pH to 1.5 to 2, react for 3.0 hours, adjust the solution pH to 3.8 after alum making, and filter to obtain j...

Embodiment 3

[0115] In this embodiment, only step S7 in embodiment 2 is changed on the basis of embodiment 2, wherein:

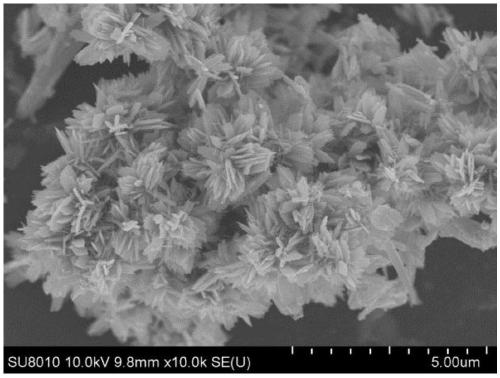

[0116] In step S7, the liquid is divided into B2 and OH-containing - The molar ratio of the solution is Zn 2+ :OH - =1:2, and add 5mL of PEG20000 solution with a mass percent concentration of 10% to the hydrothermal reaction kettle, react at 120°C for 6h, wash and dry the zinc oxide to obtain a flower-like zinc oxide composed of a sheet structure powder, such as Figure 4 As shown, it can be clearly seen from this figure that the present embodiment can indeed obtain a flower-like zinc oxide powder with a uniform structure and shape.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com