Method for treating low-concentration wastewater containing strong complex nickel

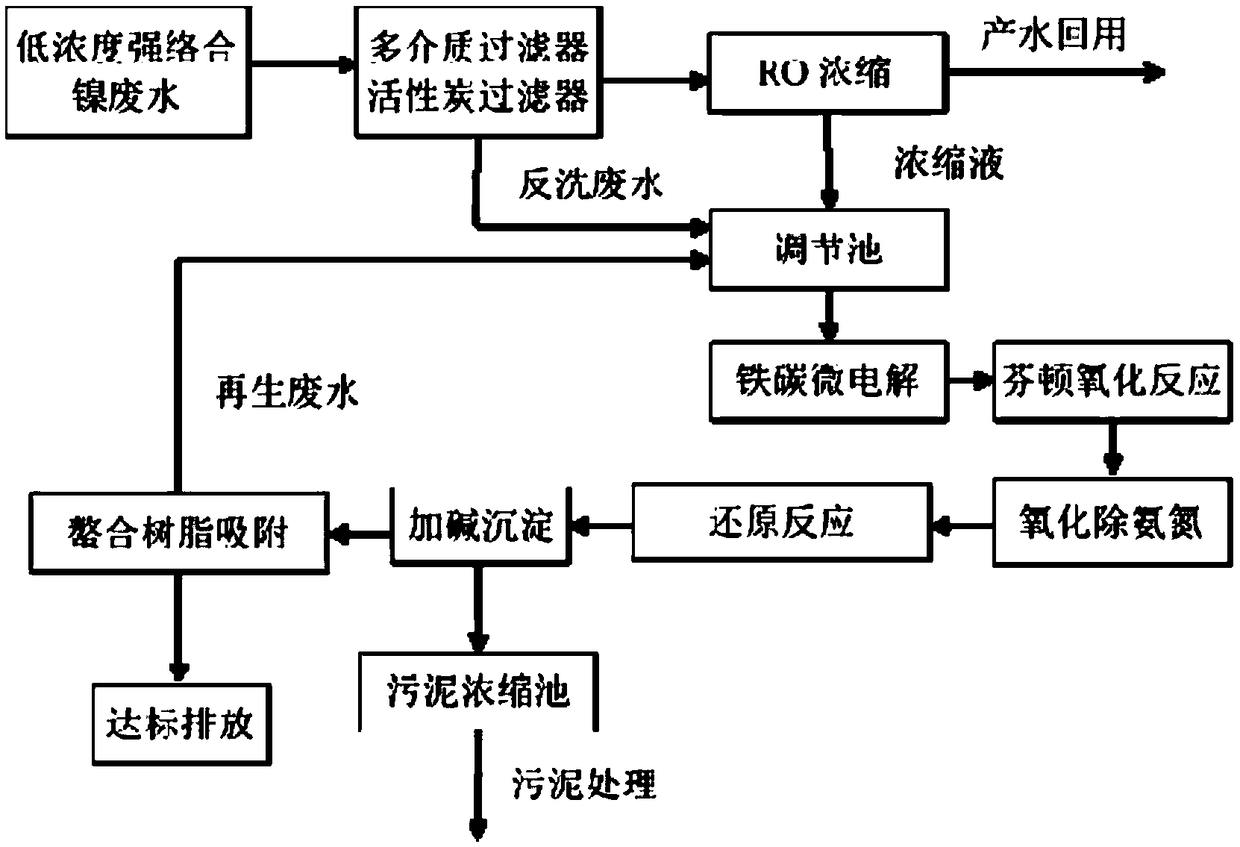

A treatment method and technology for nickel wastewater, which is applied in special compound water treatment, multi-stage water treatment, water/sewage treatment, etc., can solve the problems of low wastewater reuse rate, insufficient network breaking, and failure of total nickel in effluent to meet discharge standards, etc. problems, to achieve high water production rate, low conductivity, improve pertinence and reaction efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] The nickel-containing wastewater is: the influent water volume is 8m 3 / h, the content of COD is 50-100mg / L, the content of total nickel is 3-8mg / L, the content of EDTA is 2-4mg / L, the content of ammonia nitrogen is 50-150mg / L, and the conductivity is less than 500μs / cm.

[0032] The treatment steps of the low-concentration strong complexed nickel wastewater of the present embodiment are as follows:

[0033] In the first step, the above-mentioned low-concentration strongly complexed nickel wastewater is pretreated sequentially through a multi-media filter and an activated carbon filter, and then the pH is adjusted to 7 and concentrated by RO with a recovery rate of 75% to obtain a concentrated solution.

[0034] In the second step, adjust the pH of the concentrated solution obtained in the first step to 3, pass through the iron-carbon micro-electrolytic cell, aerate and make the wastewater stay for 30 minutes. Add 2.5L / h of H 2 o 2 (30wt.%) and 33L / h of FeSO 4 (10wt...

Embodiment 2

[0040] Low-concentration strong-complexed nickel wastewater is: the influent water volume is 10m 3 / h, the content of COD is 40~100mg / L, the content of total nickel is 6~20mg / L, the content of EDTA is 5~15mg / L, the content of ammonia nitrogen is 250~500mg / L, and the conductivity is less than 600μs / cm.

[0041] The treatment steps of the low-concentration strong complexed nickel wastewater of the present embodiment are as follows:

[0042] In the first step, the above-mentioned low-concentration strongly complexed nickel wastewater is pretreated through a multi-media filter and an activated carbon filter in sequence, and then the pH is adjusted to 6.5 and concentrated by RO to obtain a concentrated solution.

[0043] In the second step, adjust the pH of the concentrated solution obtained in the first step to be 2, pass through the iron-carbon micro-electrolytic cell, aerate and make the wastewater stay for 60 minutes. Add 3L / h of H 2 o 2 (30wt.%) and 4.2L / h of FeSO 4 (10wt....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com