1,4-butanediol dimethylacrylate preparation method

A technology of dimethacrylate and methacrylic acid, which is applied in 1 field, can solve problems such as long reaction time, high reaction temperature, and equipment corrosion, and achieve the effect of simple and easy operation, cheap and easy-to-obtain raw materials, and no corrosion of equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

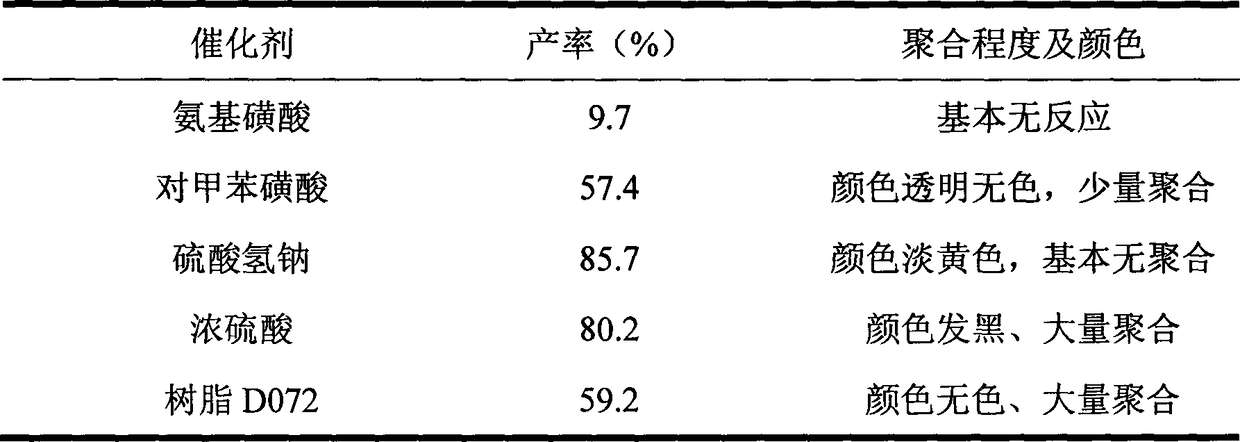

Method used

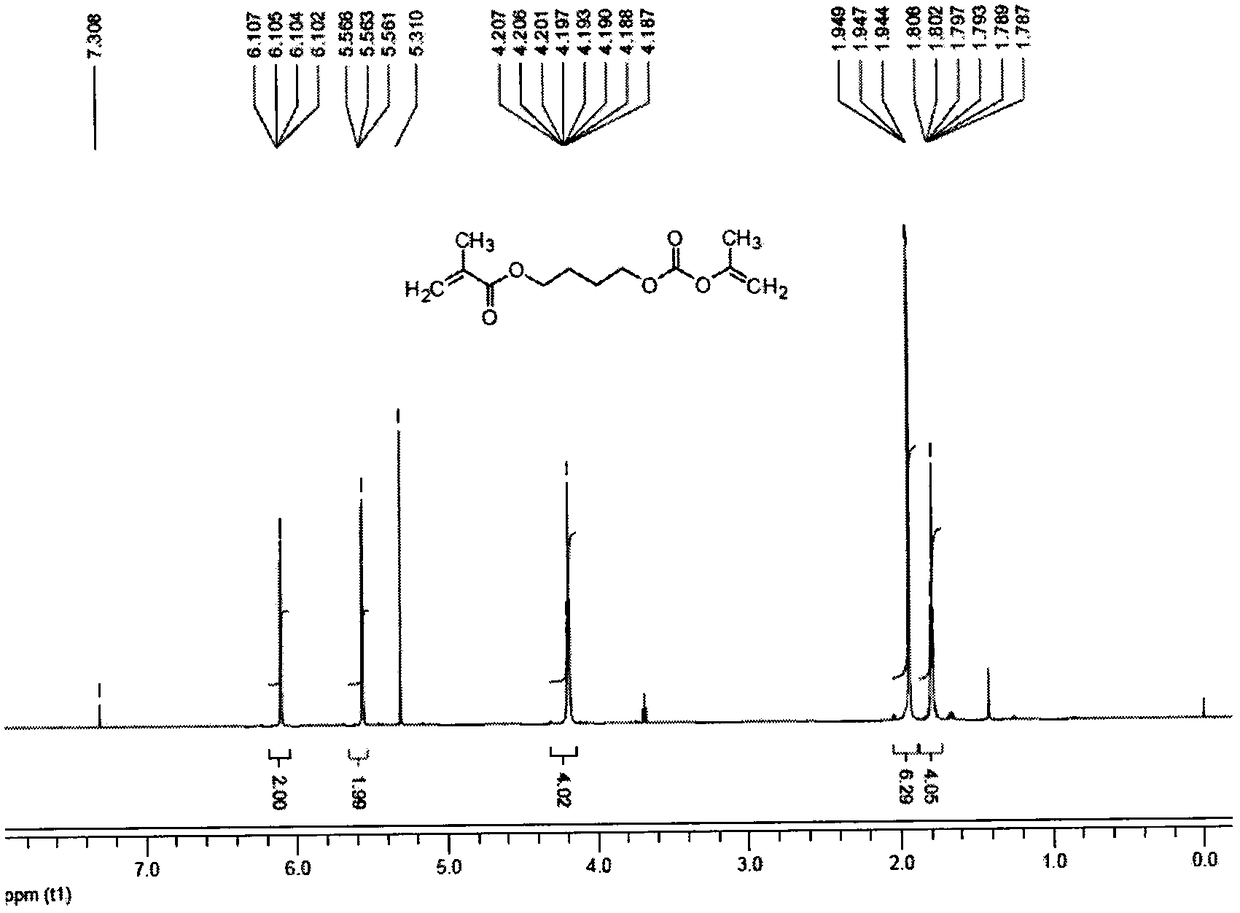

Image

Examples

Embodiment 1

[0014] This example provides a preparation method of 1,4-butanediol dimethacrylate. Take by weighing 90.39g methacrylic acid, 45.06g 1,4-butanediol (the mol ratio of methacrylic acid and 1,4-butanediol is 2.10: 1.0), 4.06g sodium bisulfate catalyst (reactant total weight 3%), 0.067g phenothiazine inhibitor (0.05% of the total weight of the reactant) and 67.73g hexamethylene (50% of the total weight of the reactant) join in the 500mL there-necked flask, put on a thermometer, reflux condensation Tube and oil-water separator, turn on magnetic stirring and heating, control the reaction temperature at 86°C, and react for 5 hours to prepare 1,4-butanediol dimethacrylate. Cool to room temperature, filter, decolorize with activated carbon, add saturated sodium bicarbonate solvent to the mixed solution to wash, then wash with distilled water for 1-2 times, let stand to separate layers, take the upper organic phase, and distill off the organic solvent under reduced pressure to obtain T...

Embodiment 2

[0016] This example provides a preparation method of 1,4-butanediol dimethacrylate. Take by weighing 88.24g methacrylic acid, 45.06g 1,4-butanediol (the mol ratio of methacrylic acid and 1,4-butanediol is 2.05: 1.0), 4.0g sodium bisulfate catalyst (reactant total weight 3%), 0.066g phenothiazine inhibitor (0.05% of the total weight of the reactant) and 66.65g hexamethylene (50% of the total weight of the reactant) join in the 500mL there-necked flask, put on a thermometer, reflux condensation Tube and oil-water separator, turn on magnetic stirring and heating, control the reaction temperature at 86°C, and react for 5 hours to prepare 1,4-butanediol dimethacrylate. Cool to room temperature, filter, decolorize with activated carbon, add saturated sodium bicarbonate solvent to the mixed solution to wash, then wash with distilled water for 1-2 times, let stand to separate layers, take the upper organic phase, and distill off the organic solvent under reduced pressure to obtain Th...

Embodiment 3

[0018] This example provides a preparation method of 1,4-butanediol dimethacrylate. Take by weighing 92.54g methacrylic acid, 45.06g 1,4-butanediol (the mol ratio of methacrylic acid and 1,4-butanediol is 2.15: 1.0), 4.13g sodium bisulfate catalyst (reactant total weight 3%), 0.069g phenothiazine inhibitor (0.05% of the total weight of the reactant) and 68.80g hexanaphthene (50% of the total weight of the reactant) join in the 500mL there-necked flask, put on a thermometer, reflux condensation Tube and oil-water separator, turn on magnetic stirring and heating, control the reaction temperature at 86°C, and react for 5 hours to prepare 1,4-butanediol dimethacrylate. Cool to room temperature, filter, decolorize with activated carbon, add saturated sodium bicarbonate solvent to the mixed solution to wash, then wash with distilled water for 1-2 times, let stand to separate layers, take the upper organic phase, and distill off the organic solvent under reduced pressure to obtain T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com