Promoter for heterologous expression of keratinase, and application thereof

A technology of keratinase and promoter, which is applied in the field of promoters for heterologous expression of keratinase, to achieve the effects of long cycle, reduced workload and high expression efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

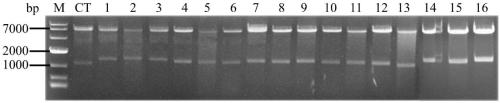

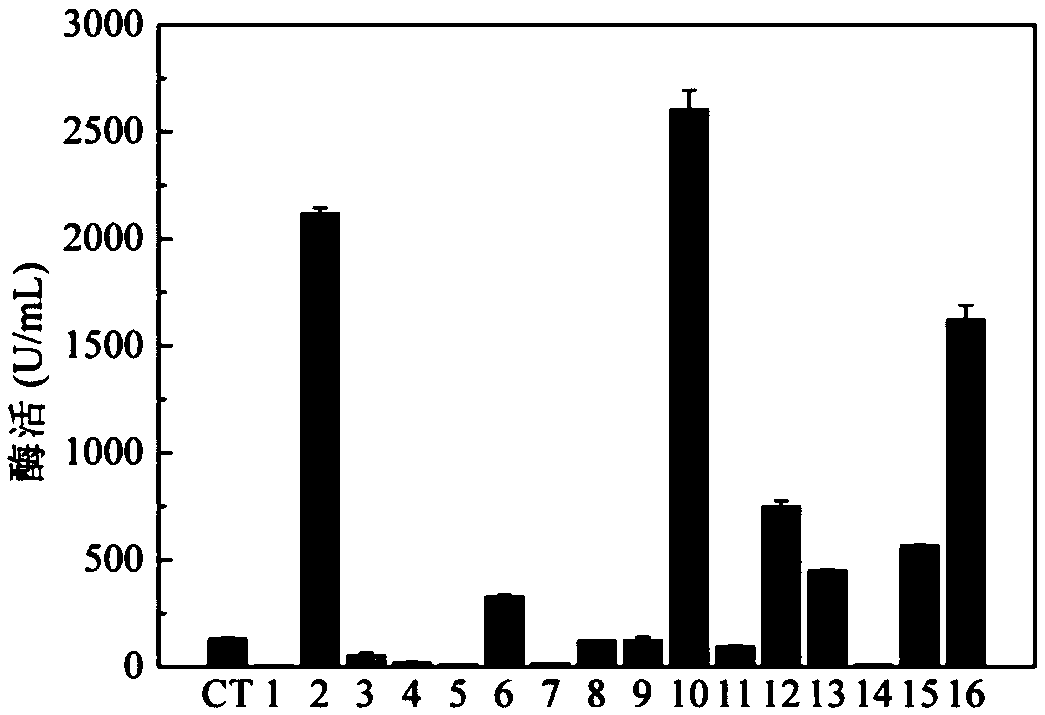

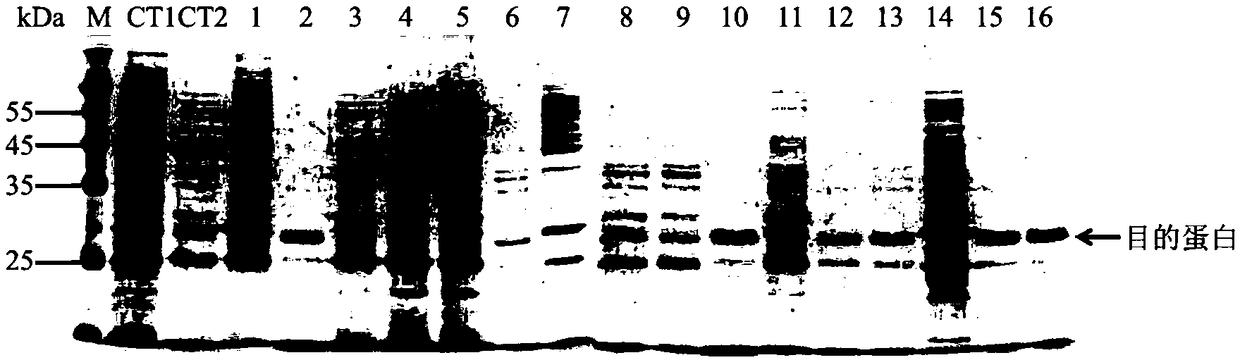

[0032] Example 1: Promoter Molecular Modification Improves Keratinase Activity and Expression

[0033] The nucleotide sequence of the promoter is amplified from the Bacillus genome and modified by mutation. In this study, the promoters selected and modified are all constitutive promoters or self-inducible promoters without adding inducers, which are trnQ, sigX, yolA, wapA, gapB, cdd, veg, mpr, nprE, The base sequences of the promoters of aprE, epr, bpr, nprB, pst, gsiB, and srfA genes are shown in SEQ ID NO: 1-SEQ ID NO: 16. According to the promoter sequences of these genes, the primers are designed in Table 1.

[0034] Table 1. Promoter primer design

[0035]

[0036] In the research on the screening of promoters for high-efficiency expression of keratinase, a promoter screening system was constructed in the Bacillus subtilis expression host. The promoter can be inserted into the coding sequence of the target gene by enzyme digestion and ligation, such as keratinase reco...

Embodiment 2

[0038] Embodiment 2: PaprE promoter transforms recombinant bacteria shaking flask fermentation situation

[0039] Nutritional components such as glycerol, maltose, sucrose, beef extract and corn steep liquor were added to the TB medium in an amount of 20 g / L, and the enzyme production levels in different culture medium were detected after inoculation of PaprE promoter-transformed recombinant bacteria. Depend on Figure 4 It can be seen that when the fermentation lasted for 30 hours, the keratinase production in the TB medium was the highest, while the keratinase production in the experimental group added nutrients at the same period was lower, which may be caused by the prolonged growth period of the recombinant strain. When fermented to 48h, compared with the control TB medium, all the experimental groups added with nutritional components showed relatively higher keratinase production. The enzyme activity reaches above 4000U / mL.

Embodiment 3

[0040] Embodiment 3: PaprE promoter transformation recombinant bacteria 5L fermentation tank fermentation situation

[0041] The situation of enzyme production by PaprE promoter-transformed recombinant bacteria in 5L tank was further investigated. During the fermentation process, after inoculation with 5% inoculum, the pH value in the fermentation broth first gradually decreased, and after about 18 hours of fermentation, the pH value began to gradually increase, accompanied by the generation of a large amount of recombinant keratinase. The cell density in the fermentation broth increases rapidly in the early stage. When the fermentation reaches 30h, the OD 600 The maximum reached was 32.2, about 2.2 times that of shake flask culture. The keratinase enzyme activity in the fermentation broth reached the highest value when it was fermented to 36h, which was 7176U / mL ( Figure 5 ), approximately 1.6 times the shake flask level. The yield of recombinant keratinase obtained in th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com