Flexible electronic skin with air permeability, moisture permeability and heat regulation performance and preparation method thereof

An electronic skin and thermal regulation technology, applied in the field of flexible electronic skin and its preparation, can solve the problems of complex preparation process, unfavorable industrialization, air permeability, moisture permeability and thermal regulation performance reduction, etc. The effect of permeability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0056] This embodiment discloses a method for preparing a flexible electronic skin with air-permeable, moisture-permeable and heat-regulating properties. The specific preparation process is as follows:

[0057] Weigh 3 to 5 g of elastic polyolefin thermoplastic elastomer nanofibers, and disperse them in 800 to 1000 mL of organic solvent ether by ultra-high-speed shearing to obtain a suspension of elastic nanofibers, and then use high-pressure airflow forming technology to take 40 to 80mL of the elastic nanofiber suspension was sprayed to prepare an elastic polyolefin copolymer nanofiber film with a thickness of 35 μm.

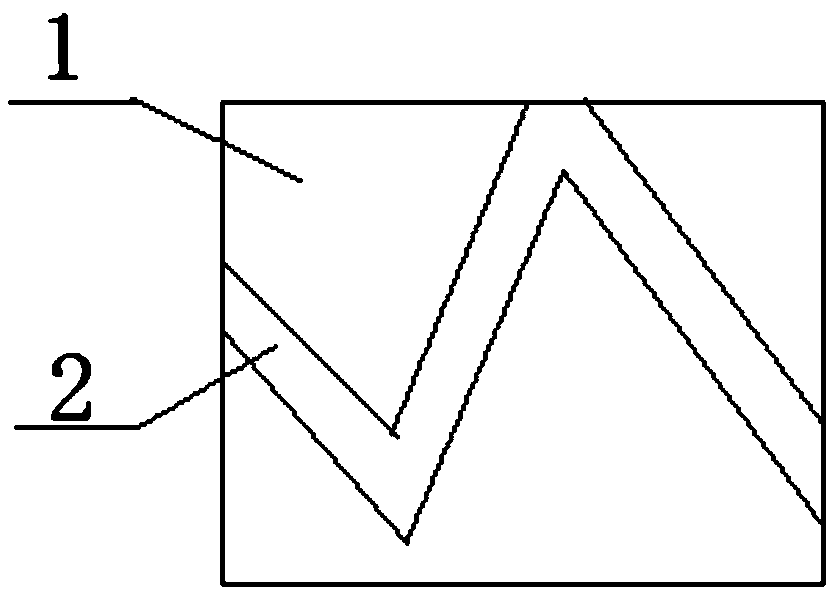

[0058] Use physical coating to coat or coat the conductive silver paste material with conductive properties on the surface of the nanofiber membrane prepared above according to the designed serpentine shape, and dry it to obtain a conductive coating with a thickness of 40 μm, that is, finally obtain a gas-permeable coating. , moisture permeability and heat regu...

Embodiment 2

[0060] This embodiment discloses a method for preparing a flexible electronic skin with air-permeable, moisture-permeable and heat-regulating properties. The specific preparation process is as follows:

[0061] Weigh 3 to 5 g of elastic polyolefin thermoplastic elastomer nanofibers, and disperse them in 800 to 1000 mL of organic solvent ether by ultra-high-speed shearing to obtain a suspension of elastic nanofibers, and then use high-pressure airflow forming technology to take 40 to 80mL of the elastic nanofiber suspension was sprayed to prepare an elastic polyolefin copolymer nanofiber film with a thickness of 60 μm.

[0062] Using physical coating, the silver nanowire material with conductive properties is coated or wrapped on the surface of the nanofiber membrane prepared above according to the designed ring, and dried to obtain a conductive coating with a thickness of 45 μm, that is, finally obtain a gas-permeable, Flexible electronic skin with moisture permeability and th...

Embodiment 3

[0064] This embodiment discloses a method for preparing a flexible electronic skin with air-permeable, moisture-permeable and heat-regulating properties. The specific preparation process is as follows:

[0065] Weigh 3 to 5 g of elastic polyolefin thermoplastic elastomer nanofibers, and disperse them in 800 to 1000 mL of organic solvent ether by ultra-high-speed shearing to obtain a suspension of elastic nanofibers, and then use high-pressure airflow forming technology to take 40 to 80mL of the elastic nanofiber suspension was sprayed to prepare an elastic polyolefin copolymer nanofiber film with a thickness of 80 μm.

[0066] Use physical coating to coat or wrap the copper nanowire material with conductive properties on the surface of the nanofiber membrane prepared above according to the designed curve, and dry it to obtain a conductive coating with a thickness of 60 μm, that is, finally obtain a gas-permeable coating. , moisture permeability and heat regulation performance ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com