A lithium ion battery negative electrode plate and a modification process thereof

A technology for lithium ion batteries and battery negative electrodes, which is applied in battery electrodes, electrode manufacturing, secondary batteries, etc., can solve problems such as the safety of negative electrode lithium dendrites, and achieve the effects of easy process control, low production cost, and prevention of internal short circuits in batteries.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

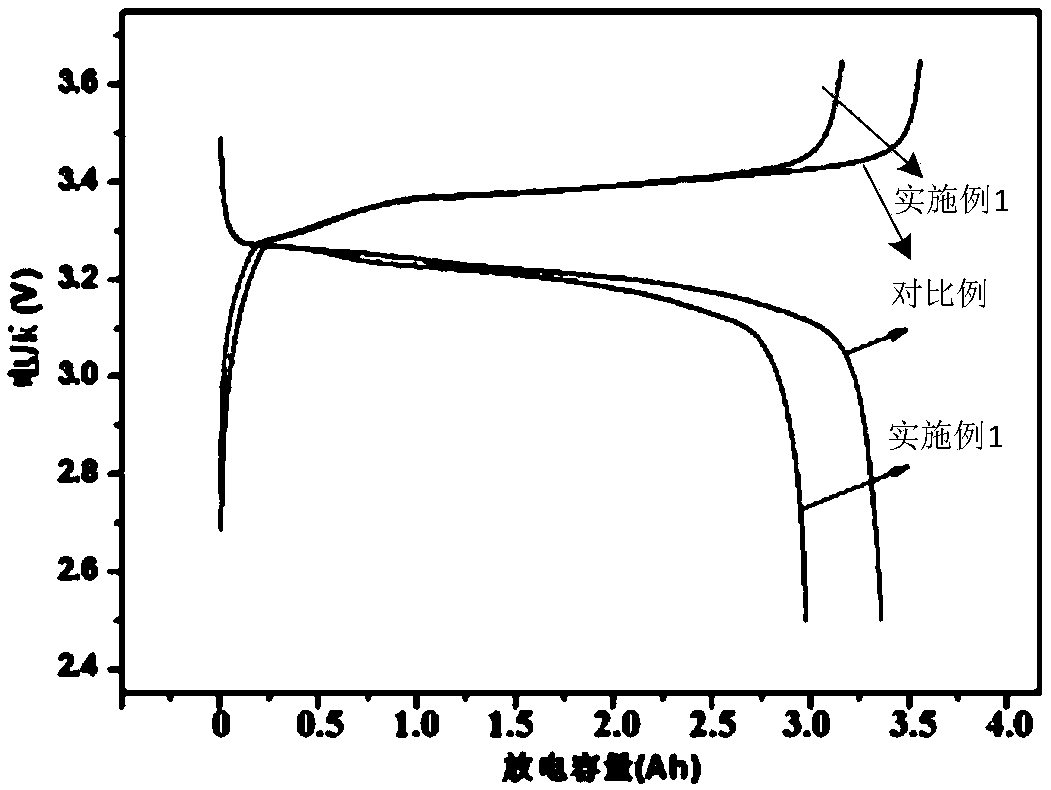

Embodiment 1

[0020] Take 10gα-Al 2 o 3 Powder, 0.8g of PVDF aqueous solution with a mass fraction of 5% and 2.375g of deionized water were mixed to form a slurry. The slurry is uniformly coated on the surface of the graphite negative electrode sheet by spraying, and the thickness is controlled at about (1-3) μm, and then the coated battery electrode sheet is placed in a room with a temperature of 40°C and a humidity of 60%. Ambient dry for 8 hours. Finally, the coated battery pole piece was dried in vacuum at 70°C for 6 hours to obtain a surface coated with α-Al 2 o 3 The graphite negative electrode sheet, such as Figure 1b As shown, it can be seen that α-Al 2 o 3 Uniformly coated on the surface of the graphite negative electrode sheet.

Embodiment 2

[0022] Take 5gα-Al 2 o 3 Powder and γ-Al 2 o 3 The powder mixture, 0.8g of 2% PVDF aqueous solution and 2.5g of deionized water were mixed to form a slurry. By spraying, the slurry is evenly coated on the surface of the graphite negative electrode sheet, and the thickness is controlled at about (3-5) μm, and then the coated battery electrode sheet is placed in a room with a temperature of 10°C and a humidity of 10%. Ambient dry for 4 hours. Finally, the coated battery pole piece was dried in vacuum at 60°C for 4 hours to obtain a surface coated with α-Al 2 o 3 and γ-Al 2 o 3 powder graphite negative electrode sheet.

Embodiment 3

[0024] Take 5g ZrO 2 Powder, 0.1 g of 10% PVDF aqueous solution and 1 g of deionized water were mixed to form a slurry. By spraying, the slurry is evenly coated on the surface of the graphite negative electrode sheet, and the thickness is controlled at about (4-6) μm, and then the coated battery electrode sheet is placed in a room with a temperature of 60°C and a humidity of 20%. Ambient drying for 10 hours. Finally, the coated battery pole piece was dried in vacuum at 80°C for 6 hours to obtain a surface coated with ZrO 2 graphite negative electrode sheet.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com