Preparation method and application of magnetic separable heterogeneous Fenotn catalyst CeO2/MZFS

A catalyst and magnetic separation technology, applied in the field of environmental engineering, can solve the problems of unrealistic water body, slow catalytic reaction rate, poor degradation effect of OFLX, etc., and achieve the effect of reducing content, reducing harm and reducing emissions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] The preparation of embodiment 1 magnetic carrier MZFS:

[0043] a. Put manganese zinc ferrite in a three-necked flask, add 0.05mol L -1 150mL of citric acid solution, stirred and reacted in a water bath at 40°C for 30-200min, and the optimum value of 180min was adopted in this example;

[0044]b. Use ammonia water to adjust the pH to 5.5, heat and stir in a water bath at 40°C for 30-200 minutes, and adopt the optimum value of 180 minutes in this embodiment;

[0045] c. Use ammonia water to adjust the pH to 10, slowly add TEOS dropwise to the three-necked flask, the mass ratio of TEOS to manganese zinc ferrite is 2.4:1, heat and stir in a water bath at 40°C for 60-300min, the most used in this example The best value is 240min;

[0046] d. After the reaction is completed, let it stand for cooling, remove the supernatant, and filter and wash the lower sediment with absolute ethanol and distilled water for 3 times, and then dry it in a positive air drying oven at 60°C for...

Embodiment 2

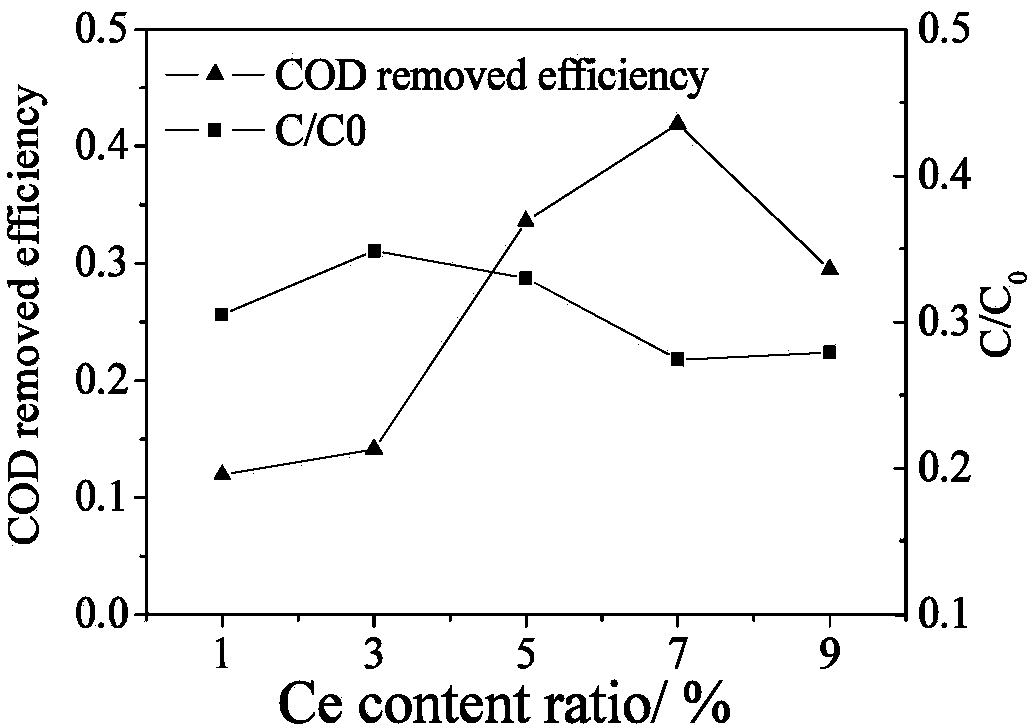

[0047] Example 2 Different cerium loadings on CeO 2 Influence of / MZFS Catalytic Performance

[0048] Take the cerium nitrate required when the loading amount of cerium is 1%, 3%, 5%, 7%, and 9% respectively (the loading amount is calculated by the ratio of the mass of cerium to the total mass of manganese, zinc and iron in MZFS), and place them in a crucible, Add 1.8mL of distilled water, stir with a glass rod to completely dissolve the cerium nitrate, add 2g of MZFS, stir evenly, let it soak for 30 minutes, put it in a water bath at 70°C for 20 minutes, and use a muffle furnace to roast at 200°C for 60 minutes in an air atmosphere After natural cooling and grinding, CeO with different loadings was prepared 2 / MZFS. figure 1 After degrading OFLX for 120min, CeO with different cerium loadings 2 The catalytic effect of / MZFS can be clearly seen from the figure. When the load is 7%, the COD removal rate can reach 41.9%, and the OFLX removal rate (1-C / C 0 ) is 72.6%, so the c...

Embodiment 3

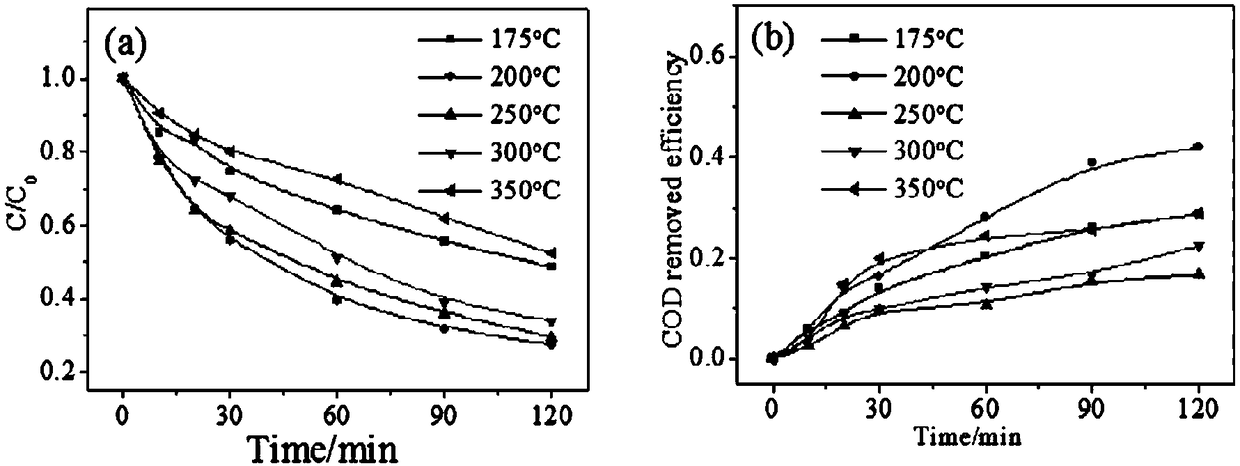

[0049] Embodiment 3 roasting temperature is to CeO 2 Influence of / MZFS Catalytic Performance

[0050] Take the required cerium nitrate when the loading capacity is 7%, put it in a crucible, add 1.8mL distilled water, stir with a glass rod to completely dissolve the cerium nitrate, add 2g MZFS, stir evenly, let it stand for 30min, and fry it in a water bath at 70°C Dry for 20 minutes, use muffle furnace, under air atmosphere, bake at 175°C, 200°C, 250°C, 300°C, 350°C for 60 minutes, cool naturally, and grind to obtain CeO with different firing temperatures 2 / MZFS, to verify their catalytic performance respectively, the results are as follows figure 2 .

[0051] figure 2 (a) CeO prepared for different calcination temperatures 2 / MZFS catalytic degradation of OFLX removal efficiency (C / C 0 ) figure, the removal effect of OFLX is the best when the calcination temperature is 200°C, and the removal rate of OFLX is 72.6% when it is degraded for 120 minutes. At 175°C, the de...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com