Preparation method for nitrogen defect modified inverse opal structure carbon nitride

A technology of structural carbon nitride and inverse opal, which is applied in the field of photocatalysis to achieve the effects of enhancing light transmission rate and utilization rate, optimizing energy band structure, and increasing active sites.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

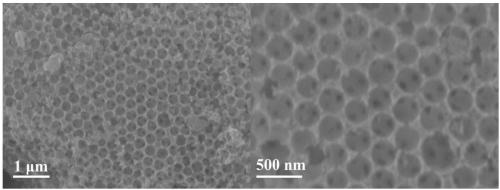

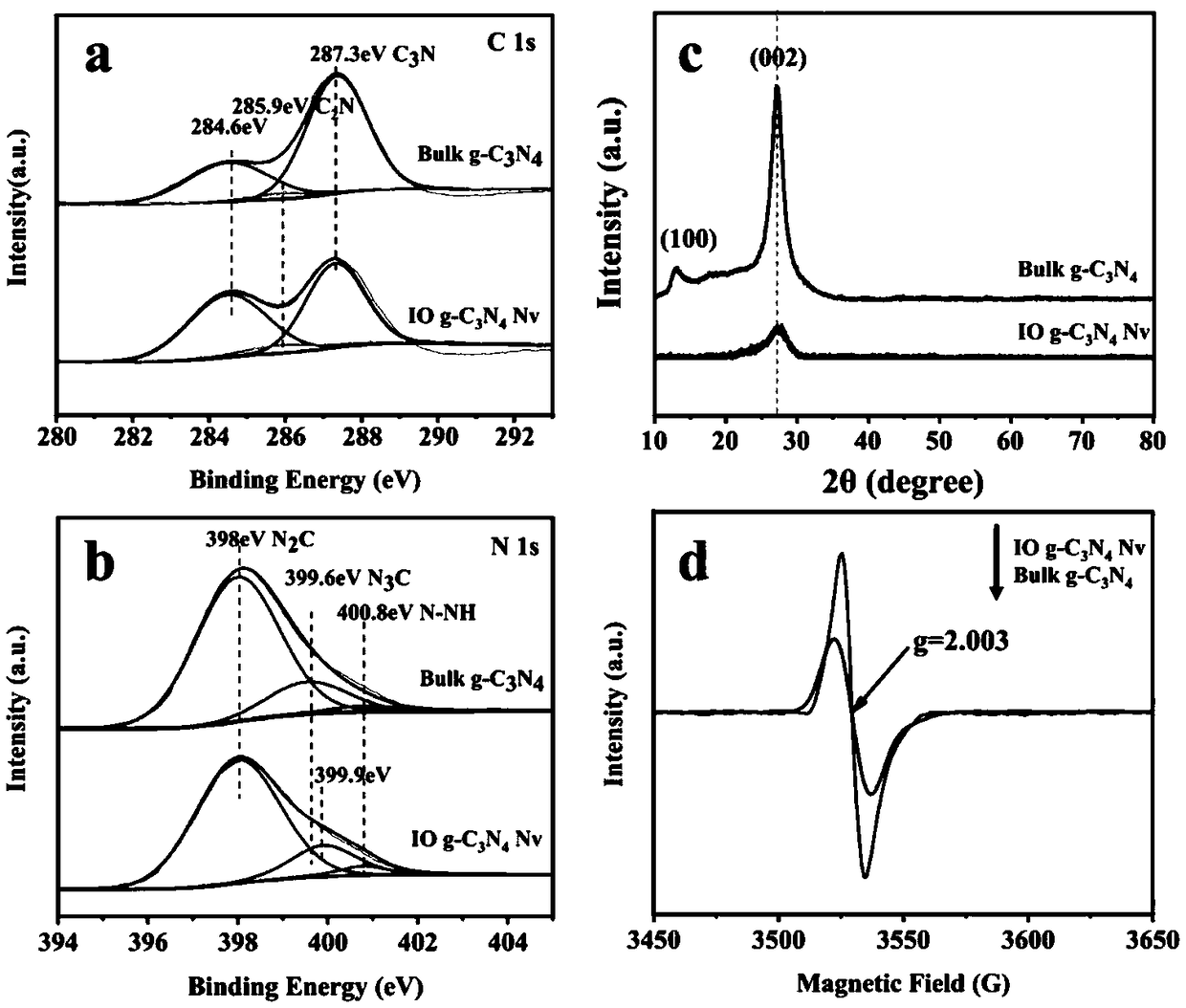

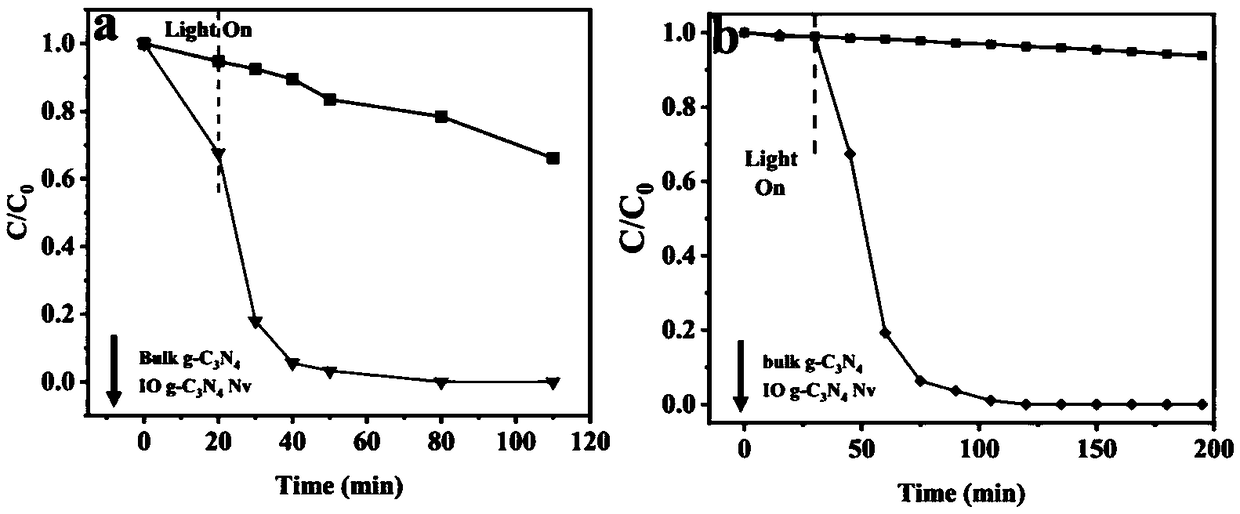

[0021] Preparation of nitrogen-deficient inverse opal-structured carbon nitride

[0022] Mix 0.6g of dicyandiamide, 1.0g of silica pellets with a diameter of about 200nm and 0.6g of ammonium chloride, grind and mix evenly, place in a porcelain ark, cover it, and put it in a tube calcined in a furnace. The heating rate was 2°C per minute, raised to 520°C and kept for 2 hours, then raised to 550°C at 4°C per minute, kept for 2 hours, and 0.2L / min of argon was continuously introduced throughout the process. After it was naturally cooled to room temperature, it was etched by 50mL 4mol / L ammonium bifluoride aqueous solution for 48h, and the centrifugal washing speed was 12500r / min, and the centrifugal time was 15min centrifugal washing, and dried to obtain 10 g-C 3 N 4 Nv.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com