Environment-friendly wood-like pencil plastic preparation process

A preparation process, pencil technology, applied in the direction of non-mechanical pencils, printing, writing utensils, etc., can solve the complex preparation process of wooden pencils and other problems, achieve the effect of convenient and easy preparation process, easy popularization, and prolong service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

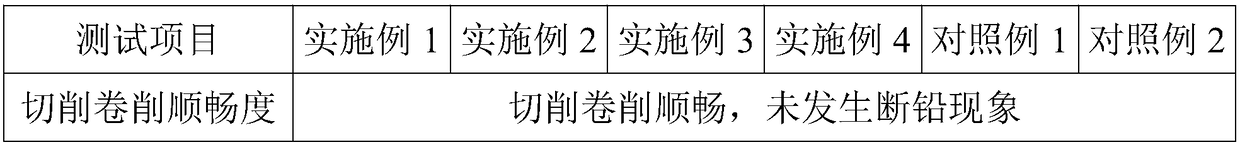

Examples

Embodiment 1

[0030] A kind of preparation technology of environment-friendly imitation wood plastic pencil, comprises the following steps:

[0031] (1) Pen core granulation: Heat the internal mixer to 160°C, start it, then add 80kg of polystyrene, 15kg of talcum powder, 15kg of thermoplastic elastomer SBS, 80kg of graphite, 0.2kg of zinc stearate, stearic acid Calcium 1.3kg, mixed evenly, banburying 3 times, extruded, cooled, made into pen core particles;

[0032] (2) Pen skin granulation: Add 90kg of polystyrene, 27kg of thermoplastic elastomer SBS, and 13kg of pigment into the skin granulator that has been heated to 160°C in advance, mix and stir evenly, heat and extrude, and cool to make granules;

[0033] (3) Pen barrel granulation: Add 50kg of polystyrene, 50kg of talc, 2.6kg of titanium dioxide, 0.3kg of zinc stearate, 1.3kg of calcium stearate, and 2kg of pigment to the pen barrel granulator that is heated to 170°C in advance In the process, mix and stir evenly, heat and extrude tw...

Embodiment 2

[0042] A kind of preparation technology of environment-friendly imitation wood plastic pencil, comprises the following steps:

[0043] (1) Pen core granulation: Heat the internal mixer to 160°C, start it, then add 80kg of polystyrene, 15kg of talcum powder, 15kg of thermoplastic elastomer SBS, 80kg of graphite, 0.2kg of zinc stearate, stearic acid Calcium 1.3kg, mixed evenly, banburying 3 times, extruded, cooled, made into pen core particles;

[0044] (2) Pen skin granulation: Add 90kg of polystyrene, 27kg of thermoplastic elastomer SBS, and 13kg of pigment into the skin granulator that has been heated to 160°C in advance, mix and stir evenly, heat and extrude, and cool to make granules;

[0045] (3) Pen barrel granulation: Add 50kg of polystyrene, 50kg of talc, 2.6kg of titanium dioxide, 0.3kg of zinc stearate, 1.3kg of calcium stearate, 2kg of pigment, and 3kg of additives into the pre-heated to 170°C In the pen holder granulator, mix and stir evenly, heat and extrude twice...

Embodiment 3

[0055] A process for preparing an environment-friendly imitation wood plastic pencil, comprising the following steps:

[0056] (1) Refill granulation: heat the mixer to 160°C, start, then add polystyrene 80kg, talc 15kg, thermoplastic elastomer SBS 15kg, graphite 80kg, zinc stearate 0.2kg, stearic acid Calcium 1.3kg, mixed evenly, banburying 3 times, extruded, cooled, and made into refill particles;

[0057] (2) Pen skin granulation: 90kg of polystyrene, 27kg of thermoplastic elastomer SBS, and 13kg of pigment are added to the skin granulator that is warmed up to 160 ℃ in advance, mixed and stirred, heated and extruded, cooled, and made into particles;

[0058] (3) Pen-holder granulation: 50kg of polystyrene, 50kg of talc, 2.6kg of titanium dioxide, 0.3kg of zinc stearate, 1.3kg of calcium stearate, 2kg of pigments, and 5kg of auxiliary agents were added to the temperature of In the pen barrel granulator, mix and stir evenly, heat and extrude for 2 times, extrude, cool, and m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com