A kind of preparation method and application of large particle sodium chromite material

A technology of sodium chromite and large particles, applied in the direction of chromate/dichromate, structural parts, electrical components, etc., can solve the problems of many influencing factors and affecting the purity of products, so as to reduce side reactions and benefit The effect of de-intercalation and small specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0047] Take a certain amount of sodium dichromate and put it into an alumina crucible, under Ar / H 2 (95%:5%v%) roasting under mixed atmosphere, the roasting temperature is 850 ℃, holding time is 10h. After the roasting is completed, cool to room temperature with the furnace, and the product obtained is NaCrO 2 Material.

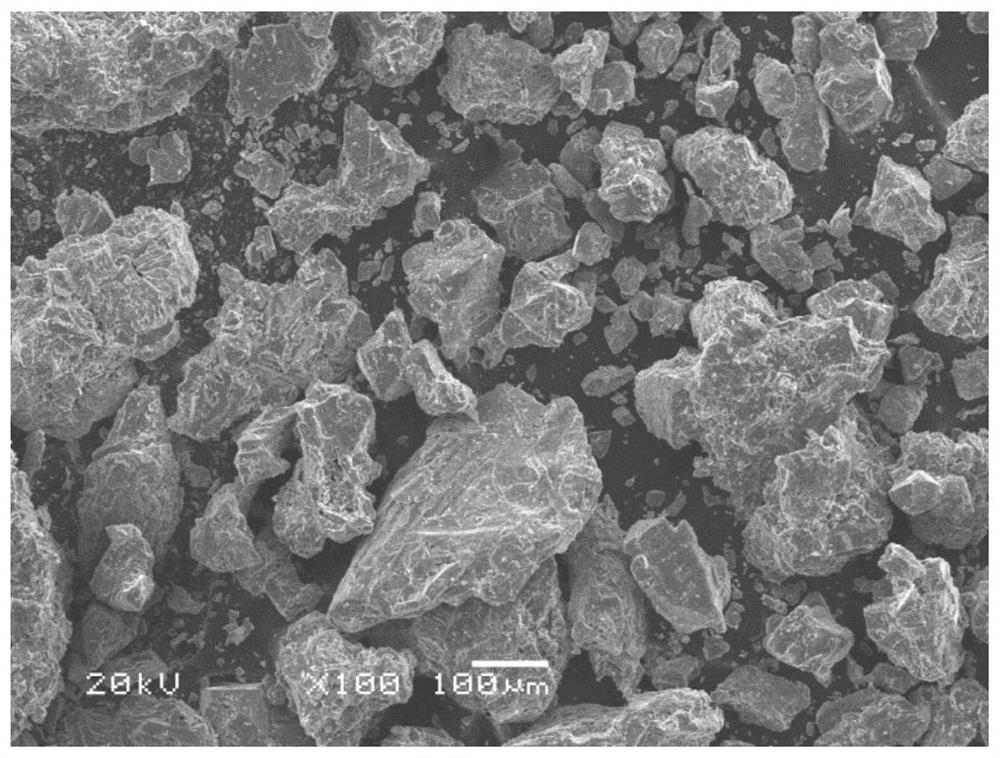

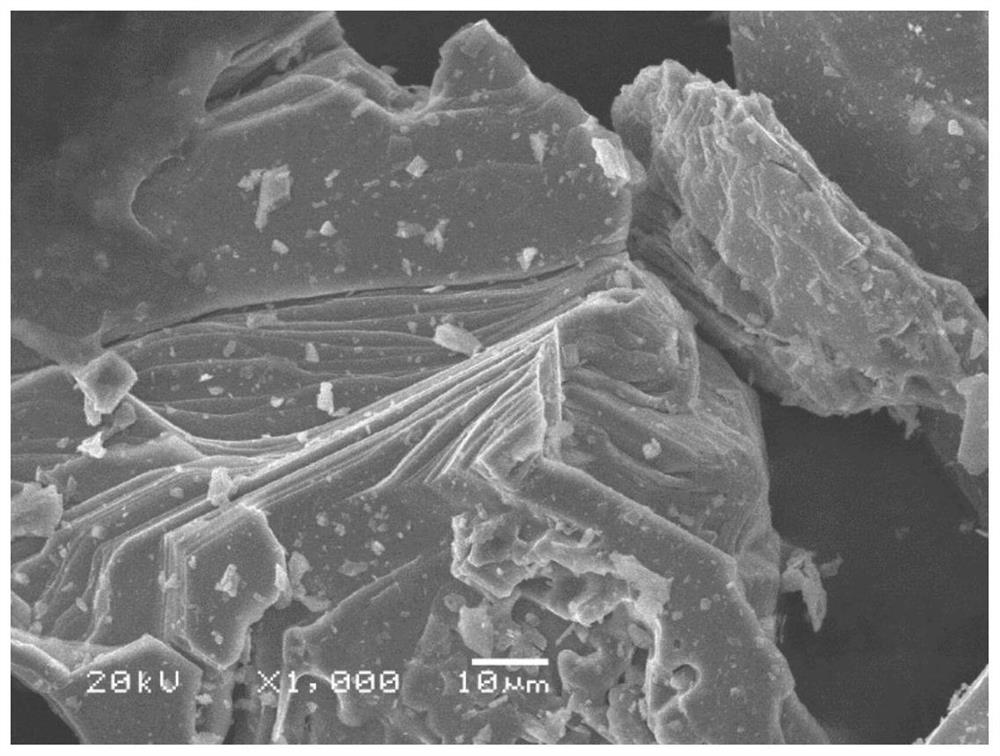

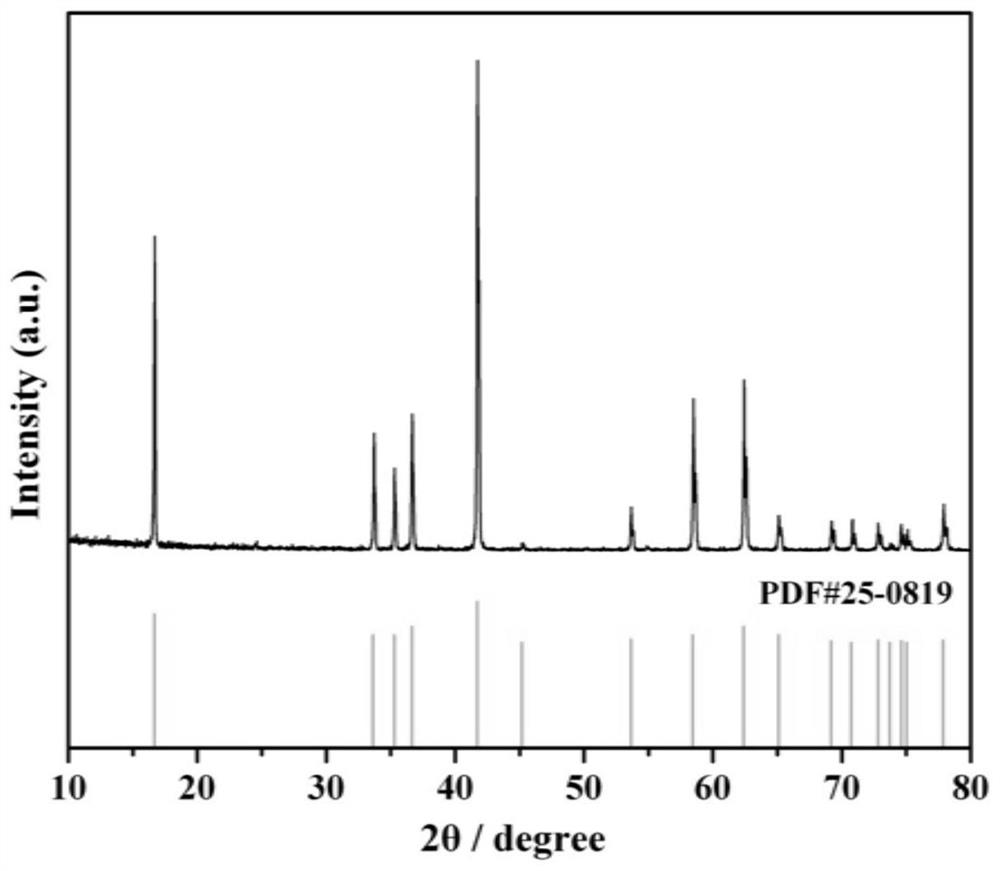

[0048] The NaCrO that the present embodiment prepares 2 The particle size is 100 ~ 1000um, in the form of irregular block particles (such as figure 1 ), the layered structure is obvious (such as figure 2 ), XRD shows that the material is an O3-type layered oxide crystal structure ( image 3 ), without other impurity phases, the tap density is 2.55g / cm 3 .

[0049] After mixing the material with acetylene black and polyvinylidene fluoride (PVDF) at a ratio of 8:1:1, add the organic solvent N-methylpyrrolidone (NMP) as a dispersant, mix evenly and spread it on the aluminum foil. Put it into an oven at 120° C. and bake for 6 to 12 hours, and then punch i...

Embodiment 2

[0051] Take a certain amount of sodium dichromate and put it into an alumina crucible, 2 / H 2 (90%: 10% v%) roasting under mixed atmosphere, the roasting temperature is 900 ℃, holding time is 15h. After the roasting is completed, cool to room temperature with the furnace, and the product obtained is NaCrO 2 . The NaCrO that the present embodiment prepares 2 The particle size is 100-500um,

[0052] The battery was assembled according to the method of Example 1, and the charge and discharge test was carried out. The current density of the test was 10mA / g, and the voltage range was 2.3-3.6V. The charge and discharge curve of the first cycle is as follows: Figure 4 As shown, it can be seen that the curve has a long plateau at about 3.0V, the average discharge voltage is about 2.97V, and the discharge specific capacity is 123.0mAh / g.

Embodiment 3

[0054] Take a certain amount of sodium dichromate and put it into an alumina crucible, under Ar / H 2 (95%:5%v%) atmosphere roasting, the roasting temperature is 850 ℃, holding time is 12h. After the roasting is completed, cool to room temperature with the furnace, and the product obtained is NaCrO 2 . The NaCrO that the present embodiment prepares 2 The particle size is 50-200um. The battery is assembled according to the method of Example 1, and the charge-discharge test is carried out. The current density of the test is 10mA / g, and the voltage range is 2.3-3.6V. Figure 5 The cycle curve of the material shows that the discharge specific capacity in the first cycle is 123.2mAh / g, after 50 cycles, the specific capacity is 119.2mAh / g, and the capacity retention rate is as high as 96.8%. It can be seen that the material shows excellent cycle stability. Image 6 It is the cycle curve graph of different rates of material, where 1C=100mA / g, the test results show that: the first di...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com