Environmental-friendly diatom ooze and preparation method thereof

A kind of diatom mud and environmental protection technology, applied in the field of decorative materials, can solve the problems of great influence of light, entering human blood, poor adsorption of formaldehyde, etc., and achieve the effect of improving catalytic efficiency, increasing reflection efficiency and increasing adsorption performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

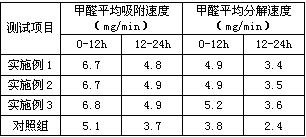

Examples

Embodiment 1

[0029] The environmentally friendly diatom mud of the present embodiment is composed of the following raw materials in parts by weight: 60 parts of modified refined diatomite, 10 parts of nano-titanium dioxide sol, 6 parts of clay, 8 parts of attapulgite, 10 parts of kaolin and 25 parts of deionized water share.

[0030] The modified refined diatomite of the present embodiment is composed of the following preparation steps:

[0031] (1) Diatomite purification: add 10 parts by weight of diatomite, 15 parts of distilled water, and 0.3 parts of dilute hydrochloric acid into the reactor, seal it and put it in a drying oven, and react at 170°C for 180 minutes , after cooling, take it out and put it into a blender, add 50 parts by weight of distilled water, set the stirring speed to 80r / min, stir for 60min, then filter with suction, wash 3 times, transfer to a dryer, and store at 100°C Dry it under the oven for 60 minutes, transfer it to a calcination furnace, and calcine it for 80...

Embodiment 2

[0039] The environmentally friendly diatom mud of the present embodiment is composed of the following raw materials in parts by weight: 70 parts of modified refined diatomite, 15 parts of nano-titanium dioxide sol, 7 parts of clay, 9 parts of attapulgite, 11 parts of kaolin and 25 parts of deionized water share.

[0040] The modified refined diatomite of the present embodiment is composed of the following preparation steps:

[0041](1) Diatomite purification: add 12 parts by weight of diatomite, 18 parts of distilled water, and 0.4 parts of dilute sulfuric acid into the reactor, seal it and put it in a drying oven, and react at 175°C for 190 minutes , after cooling, take it out and put it into a blender, add 55 parts by weight of distilled water, set the stirring speed at 90r / min, stir for 70min, then filter with suction, wash 3 times, transfer to a dryer, and set the temperature at 100°C Dry it under the oven for 70 minutes, transfer it to a calcination furnace, and calcine ...

Embodiment 3

[0049] The environment-friendly diatom mud of the present invention is composed of the following raw materials in parts by weight: 80 parts of modified refined diatomite, 20 parts of nano-titanium dioxide sol, 8 parts of clay, 10 parts of attapulgite, 12 parts of kaolin and 25 parts of deionized water .

[0050] The modified refined diatomite of the present embodiment is composed of the following preparation steps:

[0051] (1) Diatomite purification: add 15 parts by weight of diatomite, 20 parts of distilled water, and 0.5 parts of dilute nitric acid into the reactor, seal it and put it in a drying oven, and react for 200 minutes at 180°C , after cooling, take it out and put it into a blender, add 60 parts by weight of distilled water, set the stirring speed to 100r / min, stir for 80min, then filter with suction, wash 3 times, transfer to a dryer, and store at 100°C Dry it for 80 minutes, transfer it to a calcination furnace, and calcine it for 100 minutes. After calcination,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com