Synthetic mica based silver pearlescent pigment as well as preparation method and application thereof

A technology of pearlescent pigments and synthetic mica, which is applied in the direction of pigment preparation, inorganic pigment treatment, chemical instruments and methods, etc. It can solve the problems of unfavorable pearlescent system coating product quality, etc., and achieve the improvement of gloss, hiding power and hiding power Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0045] The preparation method of the described silvery pearlescent pigment based on synthetic mica, comprises the following steps:

[0046] Add water to synthetic mica to make a slurry, add soluble barium salt and soluble sulfate corresponding to barium sulfate to the slurry, coat the barium sulfate layer, and coat the first tin oxide-doped titanium dioxide on the barium sulfate layer in turn layer, a silicon dioxide layer doped with titanium dioxide and a second titanium dioxide layer doped with tin oxide, filtered, washed, dried and calcined to obtain the silver pearlescent pigment.

[0047] Preferably, the calcination temperature is 700-850°C, more preferably 760-800°C.

[0048] Preferably, the coating method of the first tin oxide-doped titanium dioxide layer and the second tin oxide-doped titanium dioxide layer specifically includes the following steps: after mixing tin tetrachloride and titanium tetrachloride solution, Doping by directly hydrolyzing the coating; more pr...

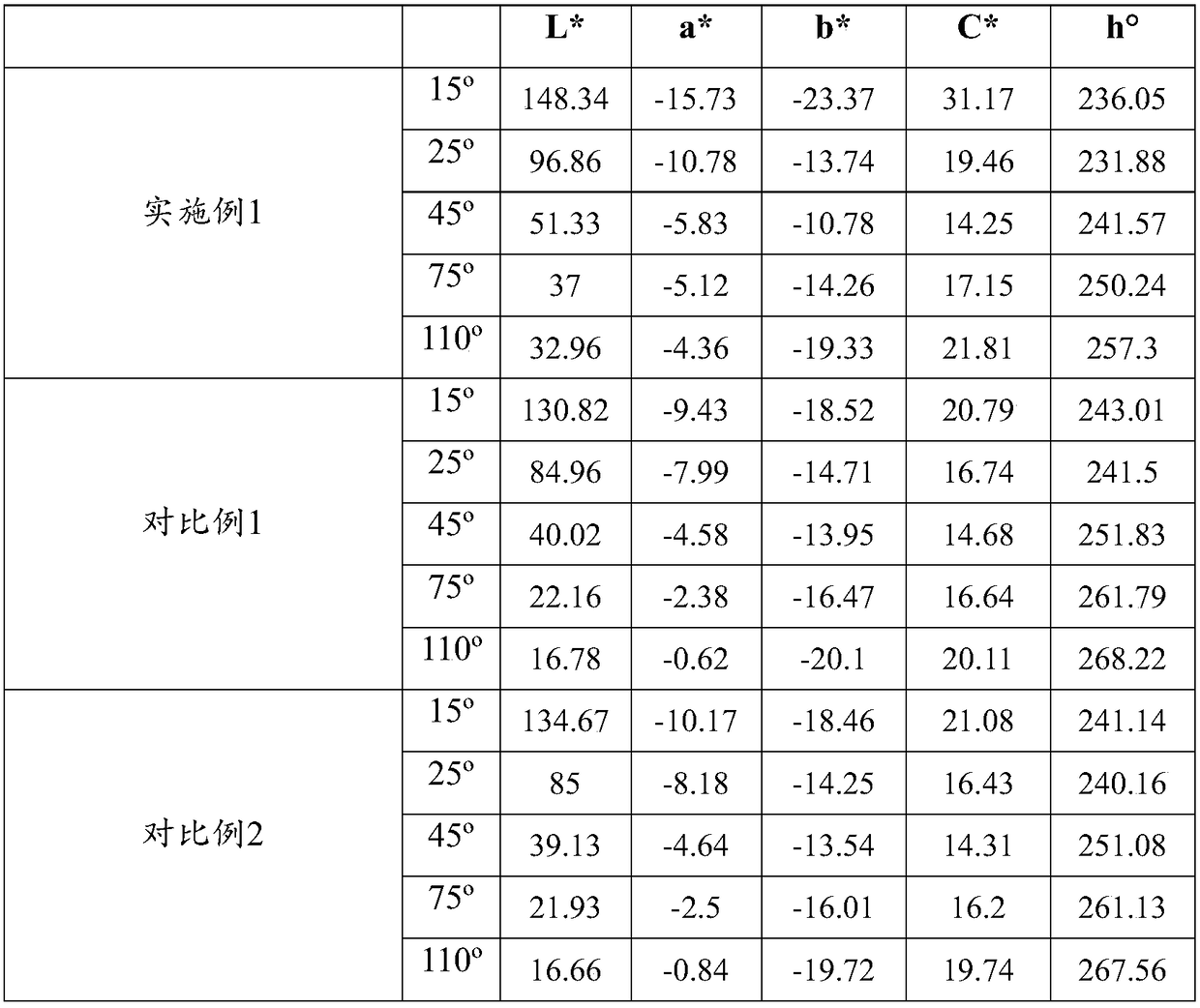

Embodiment 1

[0054] The silver pearlescent pigment provided by the application has a particle size of 20-100 μm (the average particle size is 50 μm) and a fluorphlogopite mica substrate is coated with a 5nm barium sulfate layer, a 30nm first tin oxide-doped titanium dioxide layer, and a 40nm A titania-doped silica layer and a 20 nm second tin oxide-doped titania layer.

Embodiment 2

[0056] The silver pearlescent pigment provided by the application has a particle size of 10-60 μm (average particle size is 27 μm) and a fluorphlogopite mica substrate is coated with a 10nm barium sulfate layer, a 200nm first tin oxide-doped titanium dioxide layer, and a 200nm A titania-doped silica layer and a 180 nm second tin oxide-doped titania layer.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com