FAX-modified metal halogen perovskite quantum dot and preparation method and application thereof

A perovskite, quantum dot technology, applied in chemical instruments and methods, semiconductor/solid-state device manufacturing, nanotechnology for materials and surface science, etc., can solve problems such as failure to achieve electroluminescence, and achieve suppression of by-products generation, large exciton binding energy, and particle size controllable effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] (1) Add 0.4g Cs 2 CO 3 Dissolve in a mixed solution of 15mL octadecene and 1.23mL oleic acid, under the protection of inert gas such as argon or nitrogen, heat and stir at 100-120℃ until completely dissolved to obtain a cesium oleate solution;

[0042] (2) 0.283g Rb 2 CO 3 Dissolve in a mixed solution of 15mL octadecene and 1.3mL oleic acid, under the protection of inert gas such as argon or nitrogen, heat and stir at 100-180℃ until completely dissolved to obtain rubidium oleate solution;

[0043] (3) Add 0.2g PbBr 2 Dissolve 0.094g FABr and 15mL octadecene, 3mL oleylamine and 1.23mL oleic acid in a mixed solution, put the mixed solution in a three-necked flask, heat and stir at 120℃ for 1 hour, and vent the reaction with argon or nitrogen. The oxygen and water in the system until all the reactants are dissolved; the temperature is raised to 170℃ and kept for 10 minutes, 0.55mL (140℃) of the mixed solution of rubidium and cesium oleate with a molar ratio of 1:2 is quickly inj...

Embodiment 2

[0046] The 0.2g PbBr in Example 1 2 Replace with 0.117g PbBr 2 And 0.087g PbCl 2 , The other steps are the same as in Example 1. Get Rb 0.044 Cs 0.778 FA 0.78 PbCl 1.03 Br 2.44 Deep blue perovskite quantum dots.

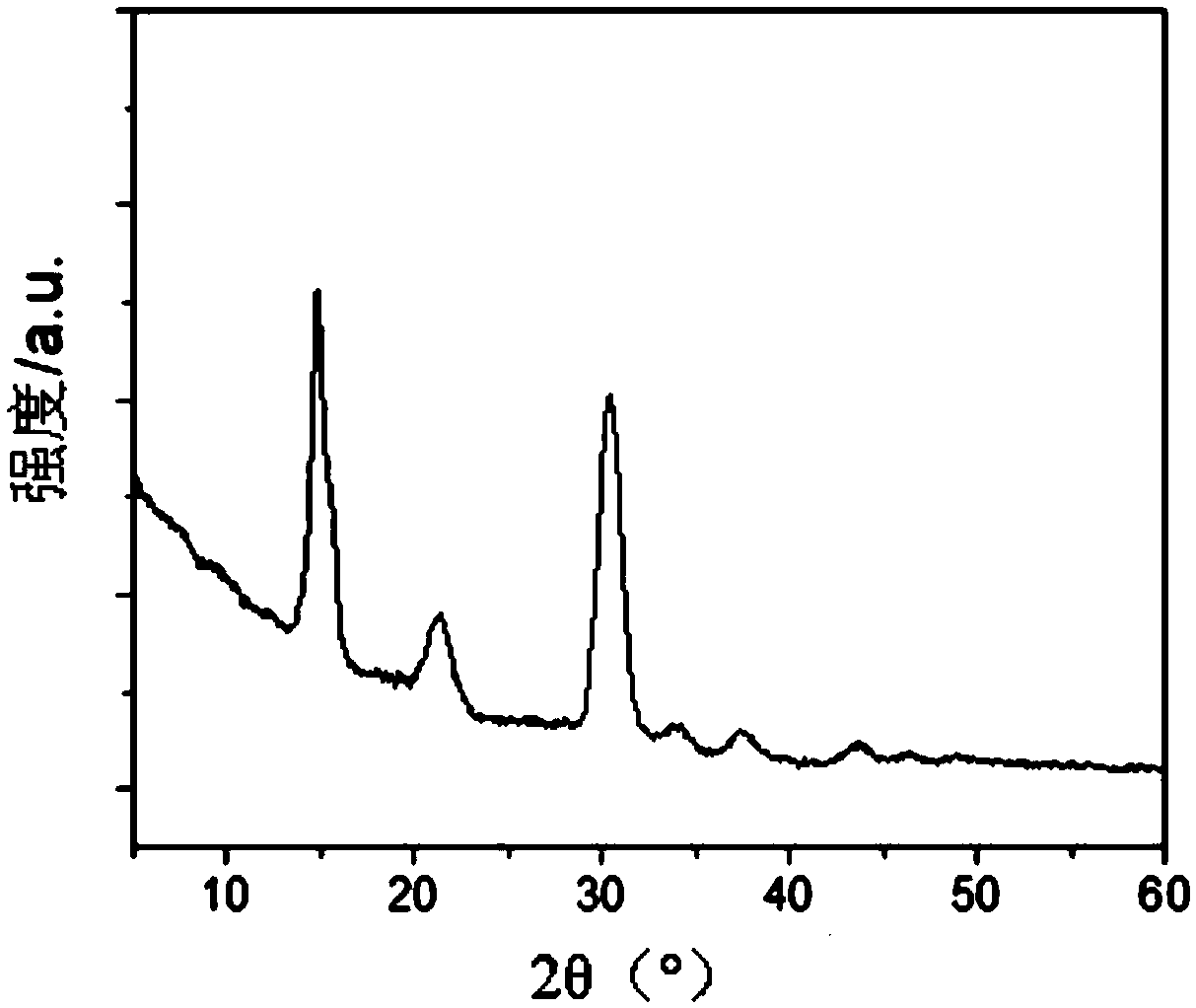

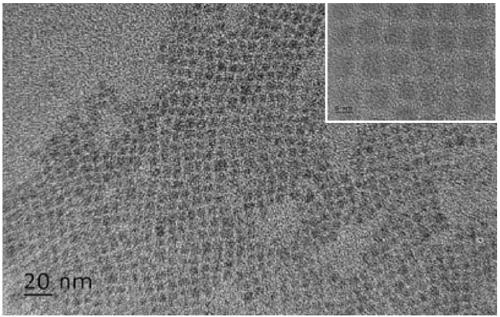

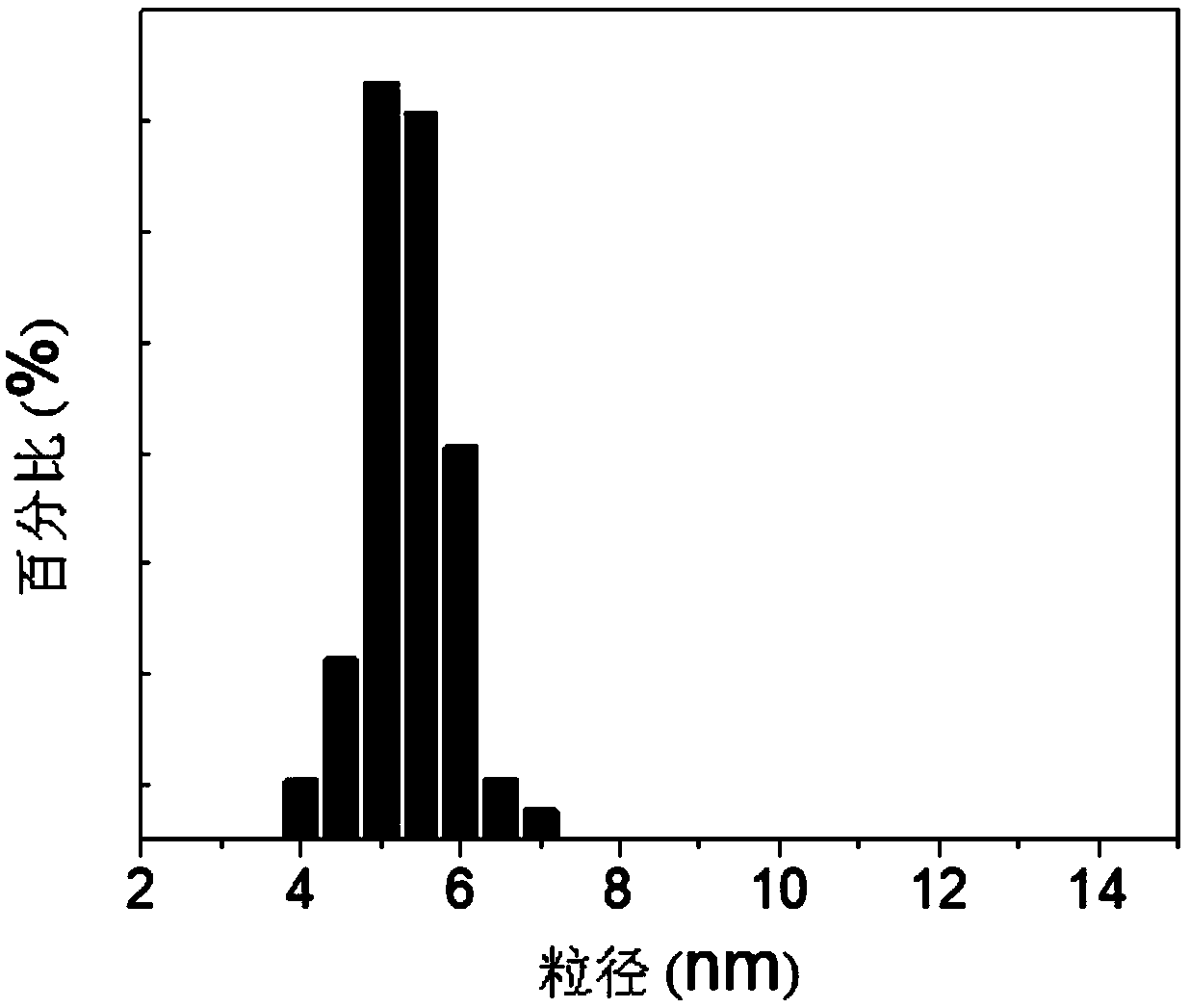

[0047] Rb obtained in this example 0.044 Cs 0.778 FA 0.78 PbCl 1.03 Br 2.44 The XRD pattern, high-resolution transmission electron microscope pattern and particle size distribution pattern of deep blue perovskite quantum dots are as follows: Figure 4~6 Shown. by Figure 4~6 It can be seen that the synthesized quantum dot material has a good cubic structure, a narrow particle size distribution, and an average particle size of 4.86 nm, showing a strong quantum confinement effect.

Embodiment 3

[0049] The 0.094g FABr in Example 1 was replaced with 0.068g FABr, and the other steps were the same as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com