Transition metal phosphide-precious metal phosphide composite fuel cell catalyst and preparation method and application thereof

A transition metal and fuel cell technology, applied in battery electrodes, circuits, electrical components, etc., can solve problems such as weak interaction, catalyst instability, particle migration, etc., to enhance interaction force, realize large-scale production, and improve contact Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

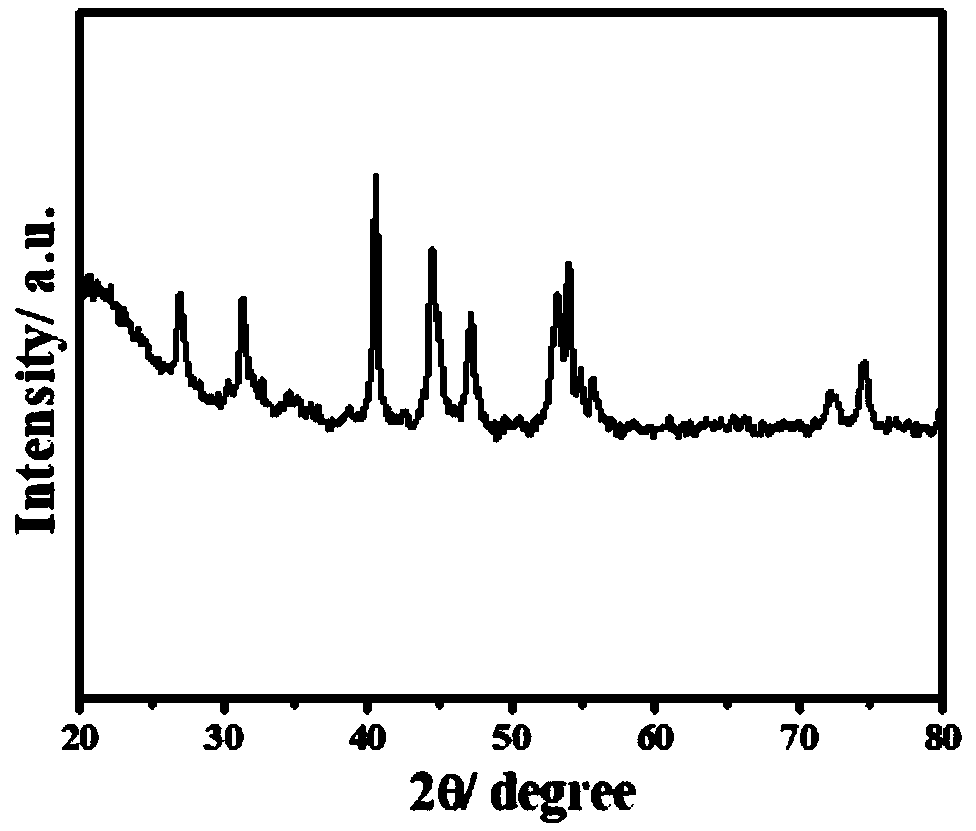

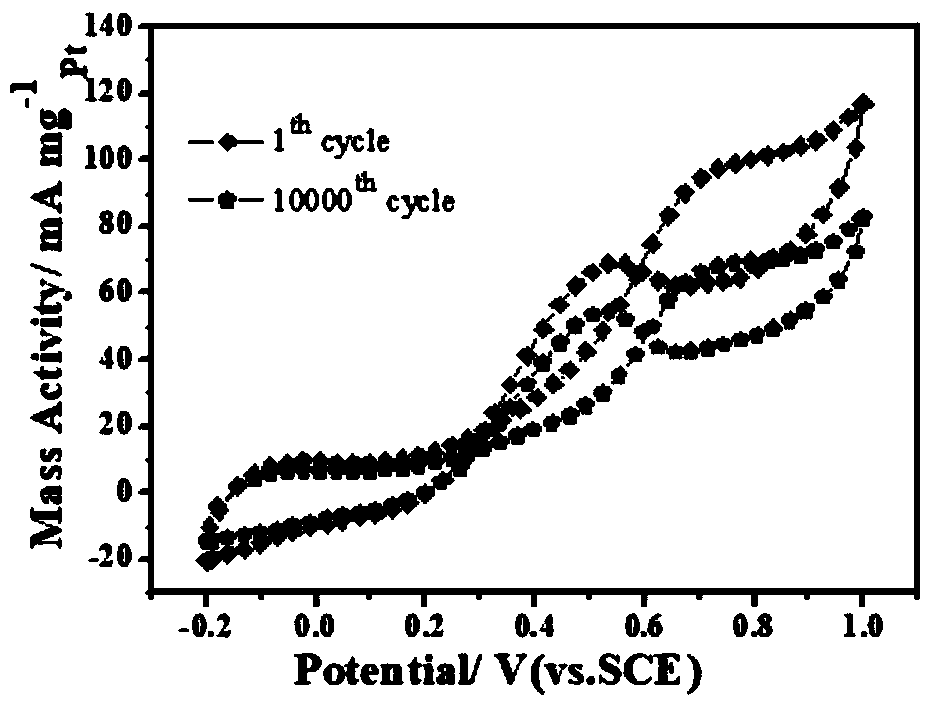

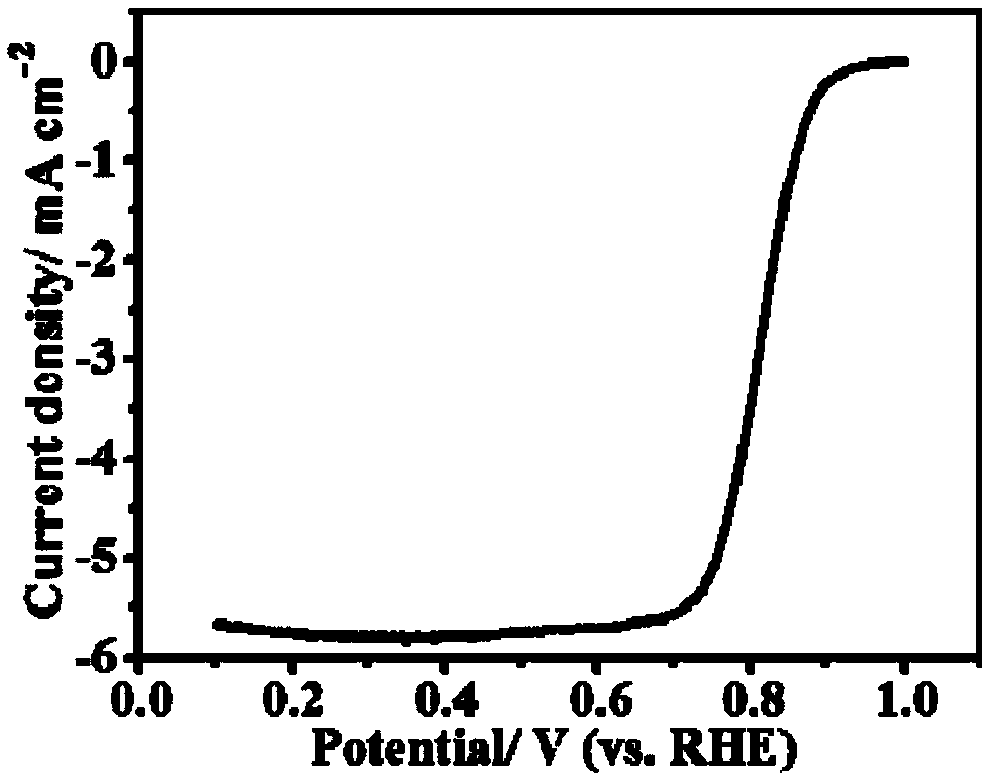

[0034] Embodiment 1: Synthesis of PtP 2 -Ni 2 P

[0035] Weigh 0.02mol of nickel chloride hexahydrate, dissolve it in 10ml of ultrapure water, stir at room temperature for 20min, add 10ml (6M) sodium hydroxide solution dropwise, continue stirring for 30min, add 0.6mmol of sodium sulfate to In the above solution, continue to stir for 10 minutes, then transfer to a 50ml autoclave, and keep at 170°C for 24 hours. Naturally cooled to room temperature, centrifuged and washed several times with ultrapure water, the obtained product was vacuum-dried at 60°C for 12 hours, and the product was Ni(OH) 2 .

[0036] Preparation of Pt-Ni(OH) 2 : Depositing Pt noble metal onto Ni(OH) 2 , using microwave-assisted alcohols-reduction method, weighed chloroplatinic acid (containing 10 mg of platinum) and 40 mg of Ni(OH) 2 Evenly disperse in 50ml of ethylene glycol, adjust the pH value to 11 with 1M sodium hydroxide solution, then heat in a 700W microwave oven for 1min, pause for 30s, repea...

Embodiment 2

[0040] Embodiment 2: Synthesis of PtP 2 -CoP

[0041] Preparation method and concrete operation are with embodiment 1, wherein with Ni(OH) 2 Change to Co(OH) 2 , while synthesizing Co(OH) 2 When replacing nickel chloride hexahydrate with cobalt chloride hexahydrate.

[0042] Figure 4 It is the PtP prepared in this embodiment 2 - TEM image of CoP, from which it is evident that PtP 2 The nanoparticles are uniformly dispersed on the CoP. Electrochemical test is identical with embodiment 1 operation, Figure 5 is PtP 2 -Cyclic voltammogram of the CoP catalyst for the electrocatalytic oxidation of ethanol, showing that the catalyst has catalytic performance for the electrocatalytic oxidation of ethanol.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com