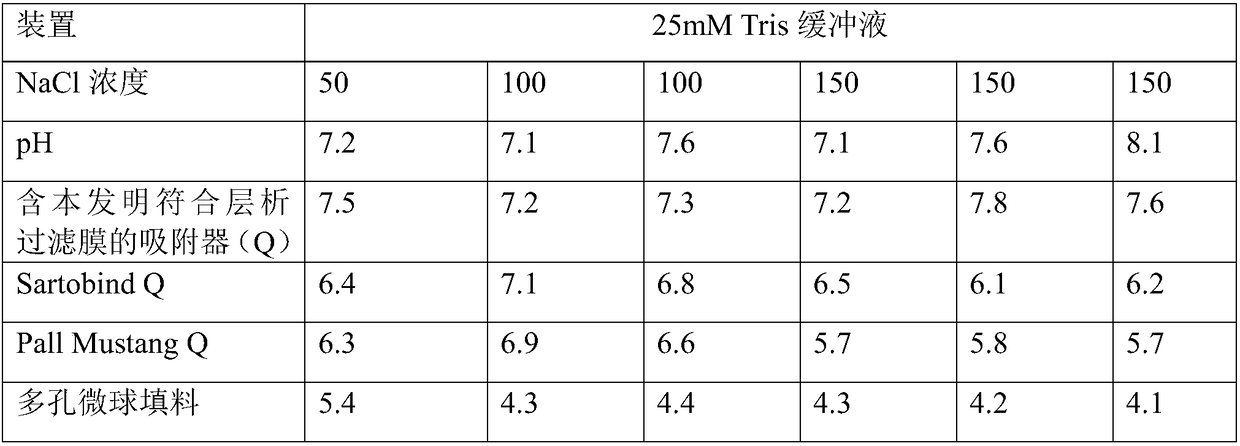

Composite chromatography filtration membrane containing adsorption medium and preparation method and application of composite chromatography filtration membrane

A technology of adsorption medium and filter membrane, which is applied in the field of composite chromatographic filter membrane and its preparation, can solve the problems of low grafting rate, low dynamic load, large floor area, etc., and achieve high flux, high surface area, uniform The effect of flow distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

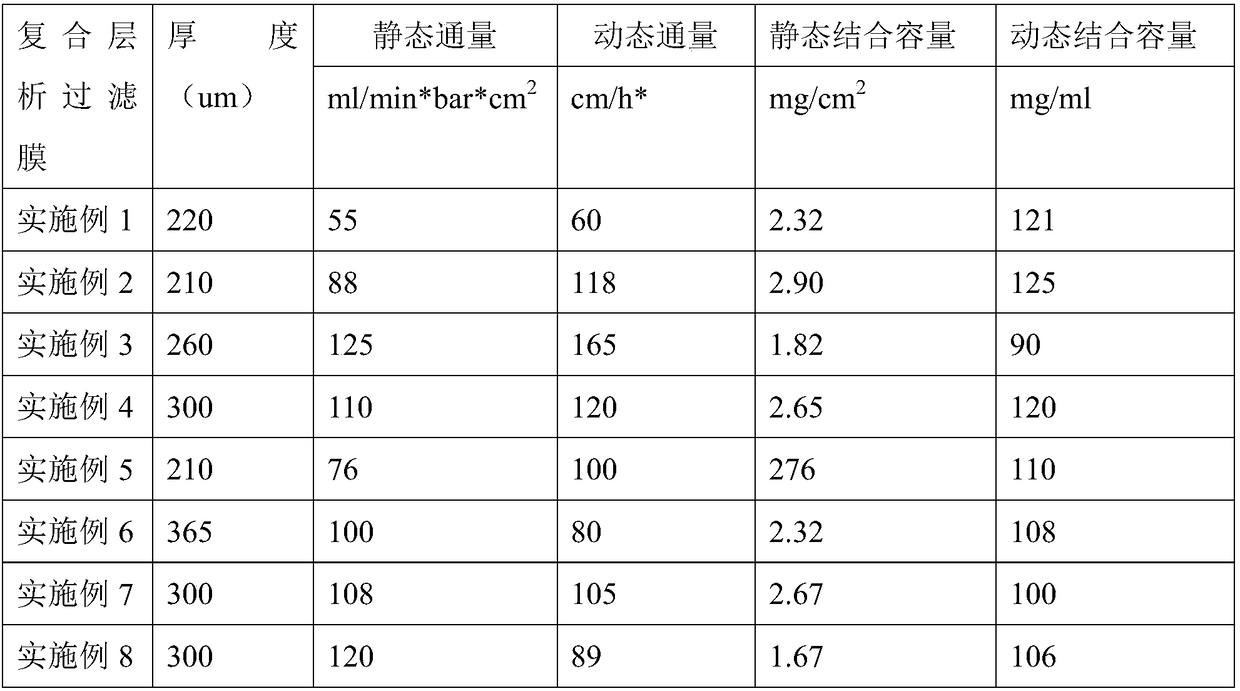

Examples

Embodiment 1

[0037] Example 1: Composite coating C18 silica gel chromatography medium

[0038] After thermally compounding a polyethersulfone microporous filter membrane with a thickness of 120um and a membrane pore size of 0.45um and a polyester non-woven fabric with a thickness of 150um, it is cut into a 20×20cm membrane, which is completely wetted with RO water , The immersion time is half an hour, the pores of the membrane are fully filled, and the water is squeezed out with double sticks; commercially available reversed-phase C18 silica gel filler with a particle size of 2-10um and a carbon loading of 10-12%. Prepared into ethanol gel solution, evenly coated on the composite filter membrane, the coating layer is a polyester non-woven fabric layer, the coating weight is 50g / ㎡, soak it in the absolute ethanol solution containing epichlorohydrin , The mass fraction ratio of epichlorohydrin in the absolute ethanol solution is 5%; after reacting at room temperature for 2 hours, the membrane i...

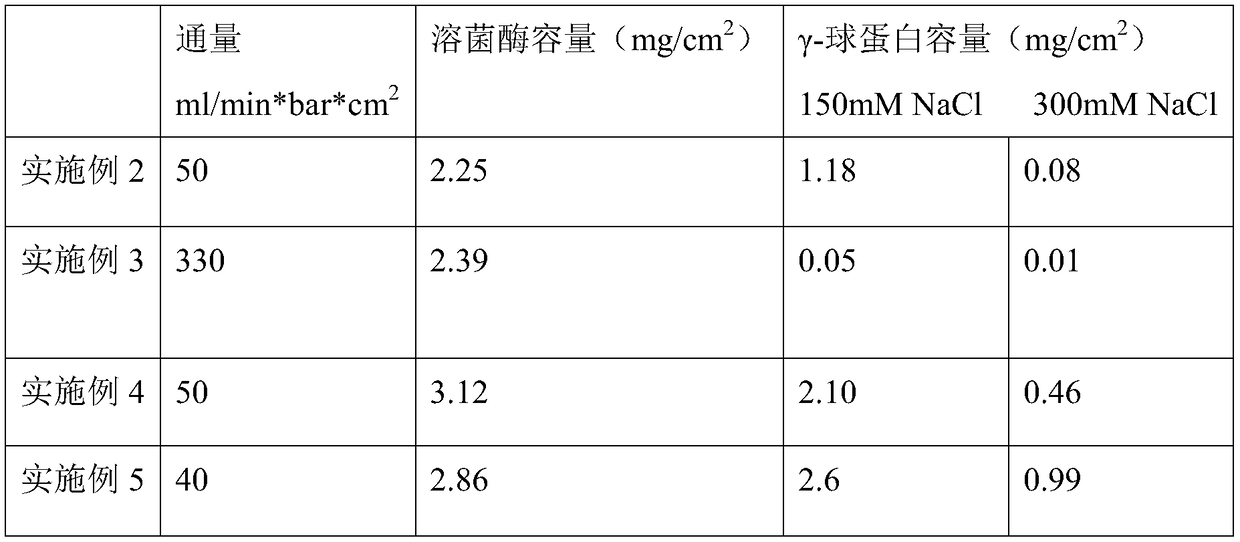

Embodiment 2

[0039] Example 2: Composite coating reversed-phase polymer chromatography medium, the surface group is phenyl

[0040] After thermally compounding a polyethersulfone microporous filter membrane with a thickness of 120um and a membrane pore size of 0.45um and a polyester non-woven fabric with a thickness of 150um, it is cut into a 20×20cm membrane, which is completely wetted with RO water , The immersion time is half an hour, the pores of the membrane are fully filled, and the water is squeezed out with double sticks; commercially available reversed-phase polymer chromatography packing, the matrix is polymethyl methacrylate, and the surface group contains phenyl groups. The particle size is 3-10um, and the chromatographic medium has a pore size of 300-500 angstroms. It is formulated into an ethanol gel solution and evenly coated on the composite filter membrane. The coating layer is a polyester non-woven fabric layer, and the coating weight is 60g / ㎡; prepare 1000 ml of N-methylo...

Embodiment 3

[0041] Example 3: Composite coating hydrophobic chromatography medium, the surface group is butyl

[0042] After thermally compounding a polyethersulfone microporous filter membrane with a thickness of 120um and a membrane pore size of 5um and a polypropylene non-woven fabric with a thickness of 200um and a pore size of 100um, they are cut into 20×20cm membranes and complete with RO water. After soaking, wetting, soaking for half an hour, the pores of the membrane are fully filled, and the water is squeezed out with double sticks; a commercially available hydrophobic chromatography filler, the matrix is polymethyl methacrylate, and the surface group contains butyl , The particle size is 15um, and the chromatographic medium has a pore size of 1000 angstroms. It is formulated into an ethanol gel solution and evenly coated on the composite filter membrane. The coating layer is polypropylene non-woven fabric layer, and the coating weight is 60g / ㎡ ; Prepare 1000 ml of N-methylol acr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com