Functional magnetic ionic liquid graphene adsorbent and preparation method and application thereof

A magnetic ionic liquid, ionic liquid technology, applied in chemical instruments and methods, preparation of test samples, other chemical processes, etc., can solve problems such as lack of dispersibility and limited functionalization of graphene

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

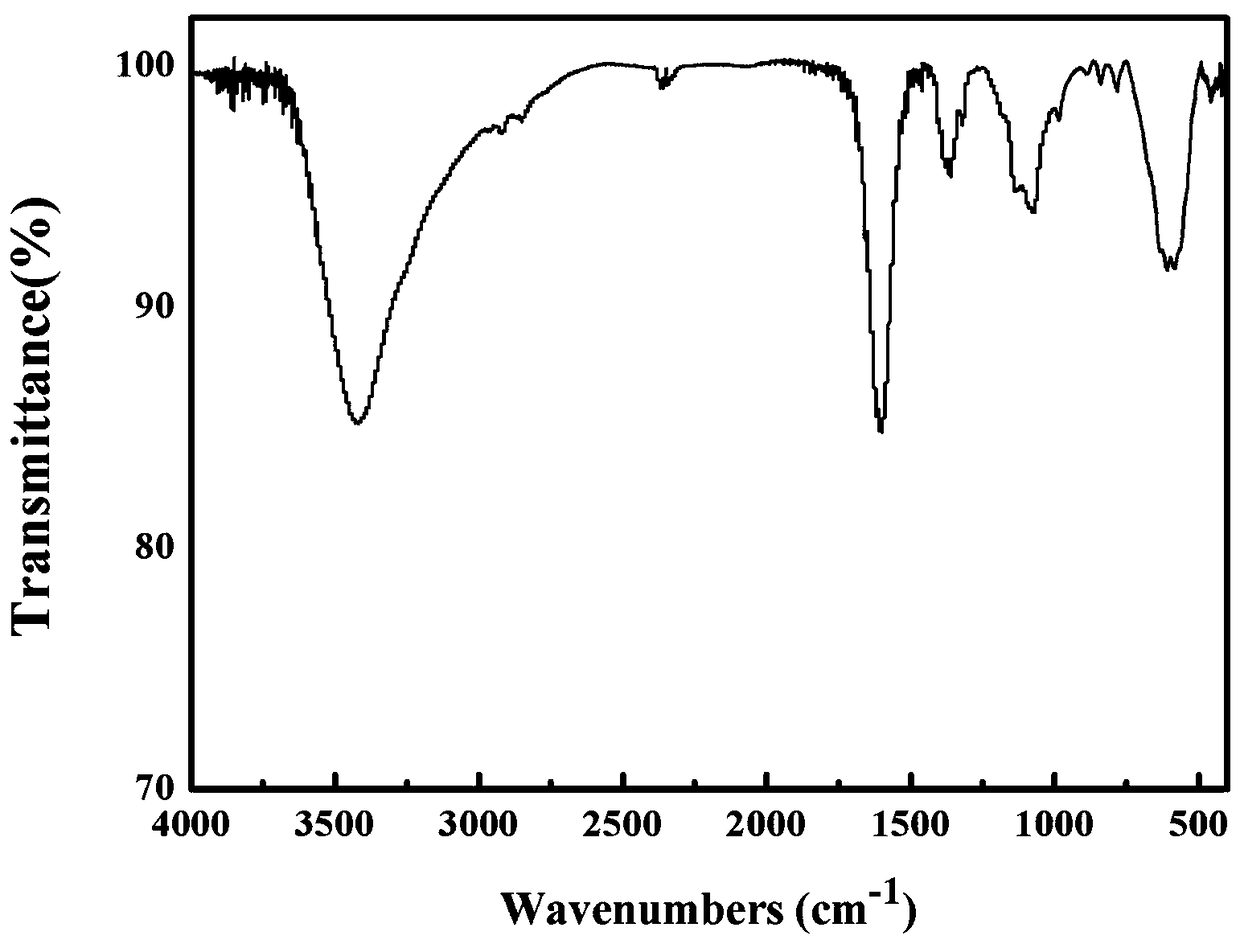

[0027] The preparation method of magnetic ionic liquid graphene adsorbent comprises the following steps:

[0028] S1. Synthesis of functional magnetic ionic liquid: the ionic liquid 1-butyl-3-methylimidazolium chloride ([C 4 min]Cl) and FeCl 3 ·6H 2 O according to the molar ratio of 1:1, mechanically stirred and reacted at 60°C for 24h, and left to stand to obtain a dark brown-yellow liquid. The dark brown-yellow liquid was divided into two layers, an aqueous phase and an ionic liquid phase, and the upper aqueous phase was poured The lower layer was washed twice with distilled water, and the unreacted raw materials were completely removed. Most of the water phase in the ionic liquid was removed by rotary vacuum evaporation, and then vacuum-dried at 80°C for 48 hours to obtain a pure magnetic ionic liquid-1-butyl -3-methylimidazolium tetrachloride ferric salt ([C 4 min] FeCl 4 );

[0029] S2. Synthesis of magnetic graphene: Accurately weigh 0.1000g of graphene powder, 2.94...

Embodiment 2

[0031] The preparation method of magnetic ionic liquid graphene adsorbent comprises the following steps:

[0032] S1. Synthesis of functional ionic liquid: the ionic liquid 1-butyl-3-methylimidazolium bromide ([C 4 min]Br) and FeCl 3 ·6H 2 O according to the molar ratio of 1:1, mechanically stirred and reacted at 25°C for 6 hours, and left to stand to obtain a dark brown-yellow liquid. The dark brown-yellow liquid was divided into two layers, an aqueous phase and an ionic liquid phase, and the upper aqueous phase was poured The lower layer was washed twice with distilled water, and the unreacted raw materials were completely removed. Most of the water phase in the ionic liquid was removed by rotary vacuum evaporation, and then vacuum-dried at 70°C for 24h to obtain a pure magnetic ionic liquid [C 4 min] FeBrCl 3 ;

[0033] S2. Synthesis of magnetic graphene: Accurately weigh 0.0390g of graphene powder, 11.110g of 1-butyl-3-methylimidazole bromide, and 4.952g of 1-butyl-3-m...

Embodiment 3

[0035] The preparation method of magnetic ionic liquid graphene adsorbent comprises the following steps:

[0036] S1. Synthesis of functional ionic liquid: the ionic liquid 1-hexyl-3-methylimidazolium chloride ([C 6 min]Cl 4 ) with FeCl 3 ·6H 2O according to the molar ratio of 1:1, mechanically stirred and reacted at 60°C for 24h, and left to stand to obtain a dark brown-yellow liquid. The dark brown-yellow liquid was divided into two layers, an aqueous phase and an ionic liquid phase, and the upper aqueous phase was poured The lower layer was washed twice with distilled water, and the unreacted raw materials were completely removed. Most of the water phase in the ionic liquid was removed by rotary vacuum evaporation, and then vacuum-dried at 80°C for 48 hours to obtain a pure magnetic ionic liquid-1-butyl -3-methylimidazolium tetrachloride ferric salt ([C 6 min] FeCl 4 );

[0037] S2. Synthesis of magnetic graphene: Accurately weigh 0.0399g graphene powder, 10.9901g 1-b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com