Single-bed two-stage furfural, paper pulp and lignin polygeneration system and method capable of achieving continuous operation

A technology of lignin and polygeneration, applied in separation methods, chemical instruments and methods, papermaking, etc., can solve the problems of poor economy and market flexibility, single process products, large solid waste discharge, etc., to achieve promotion The effect of intricate distribution, increasing furfural yield, and avoiding secondary reactions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

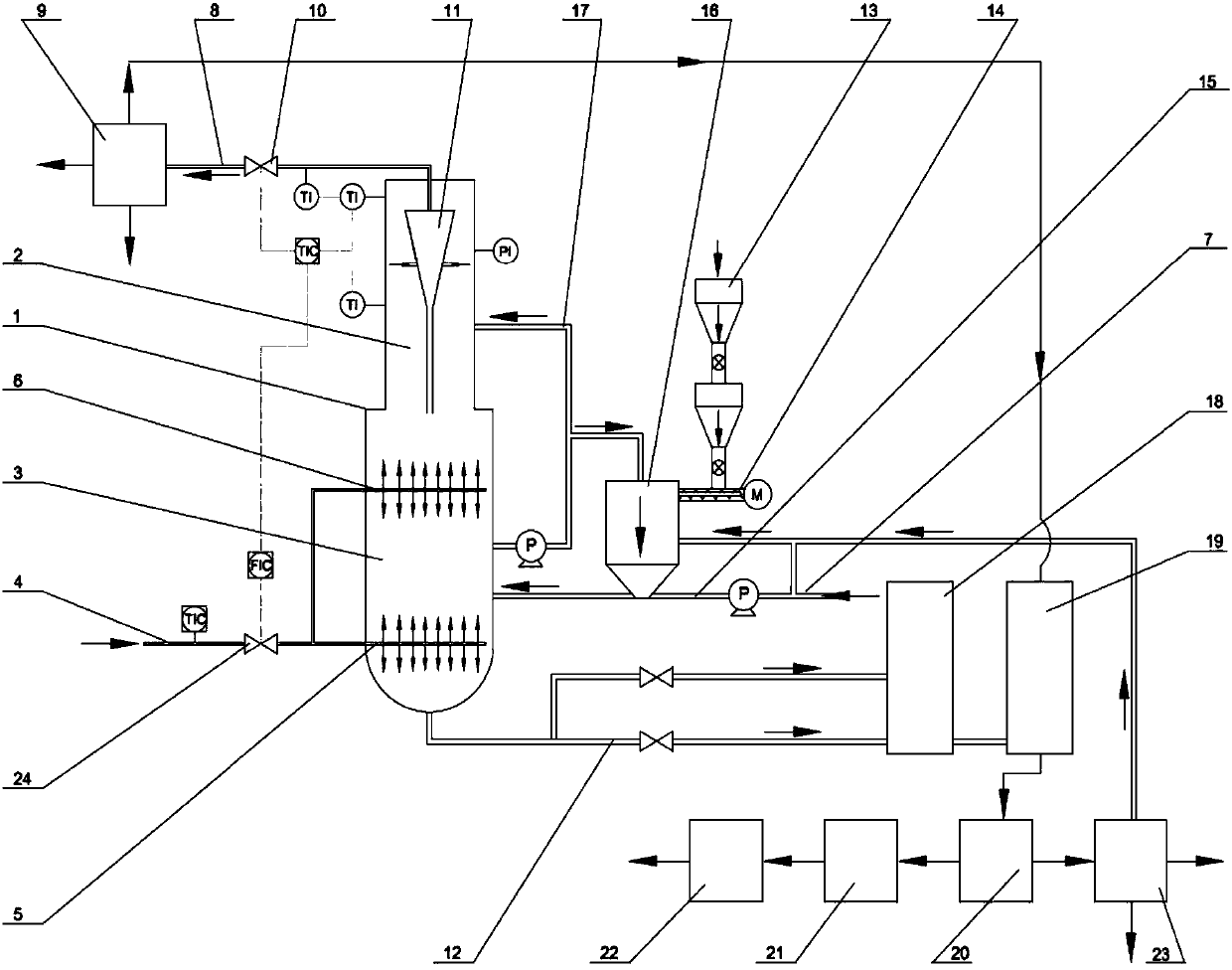

[0024] (Example 1, see figure 1 )

[0025] This embodiment comprises a raw material feeding unit 13, a dipping tank 16, a catalyst solvent feeding unit 7, a pressurized reactor 1, a steam inlet unit, a furfural rectifying unit 9, a liquid-solid product unloading unit, a washing unit 19, Pulp collection unit and lignin extraction unit 23. The pressurized reactor 1 adopts a single-bed two-stage structure, including the stripping section 2 of the reactor with a small cross-sectional area on the upper side and the mixed cooking section 3 of the reactor with a larger cross-sectional area on the lower side to increase the gas velocity of the stripping section 2 and quickly remove the generated furfural to avoid secondary reactions to increase the yield of furfural; corn cob, FeCl 3 (60mmol / L), the mixture of acetic acid (5wt%) is mixed in dipping tank 16 to carry out pretreatment to raw material, thereby improves the processing effect and efficiency of reactor, reduces the residen...

Embodiment 2

[0026] (Example 2, see figure 1 )

[0027] The difference between this embodiment and embodiment 1 is: sawdust, Al 2 (SO 4 ) 3 The mixture of acetic acid and acetic acid is mixed in the dipping tank 16 to pretreat the raw materials, thereby improving the treatment effect and efficiency of the reactor, reducing the residence time of the material in the reactor, and improving the yield of furfural and pulp; the pre-mixed material enters the reactor Mixed cooking stage 3, mixed with water vapor and in Al 2 (SO 4 ) 3 Various reactions take place under the catalysis of acetic acid; Other system composition is identical with embodiment 1.

Embodiment 3

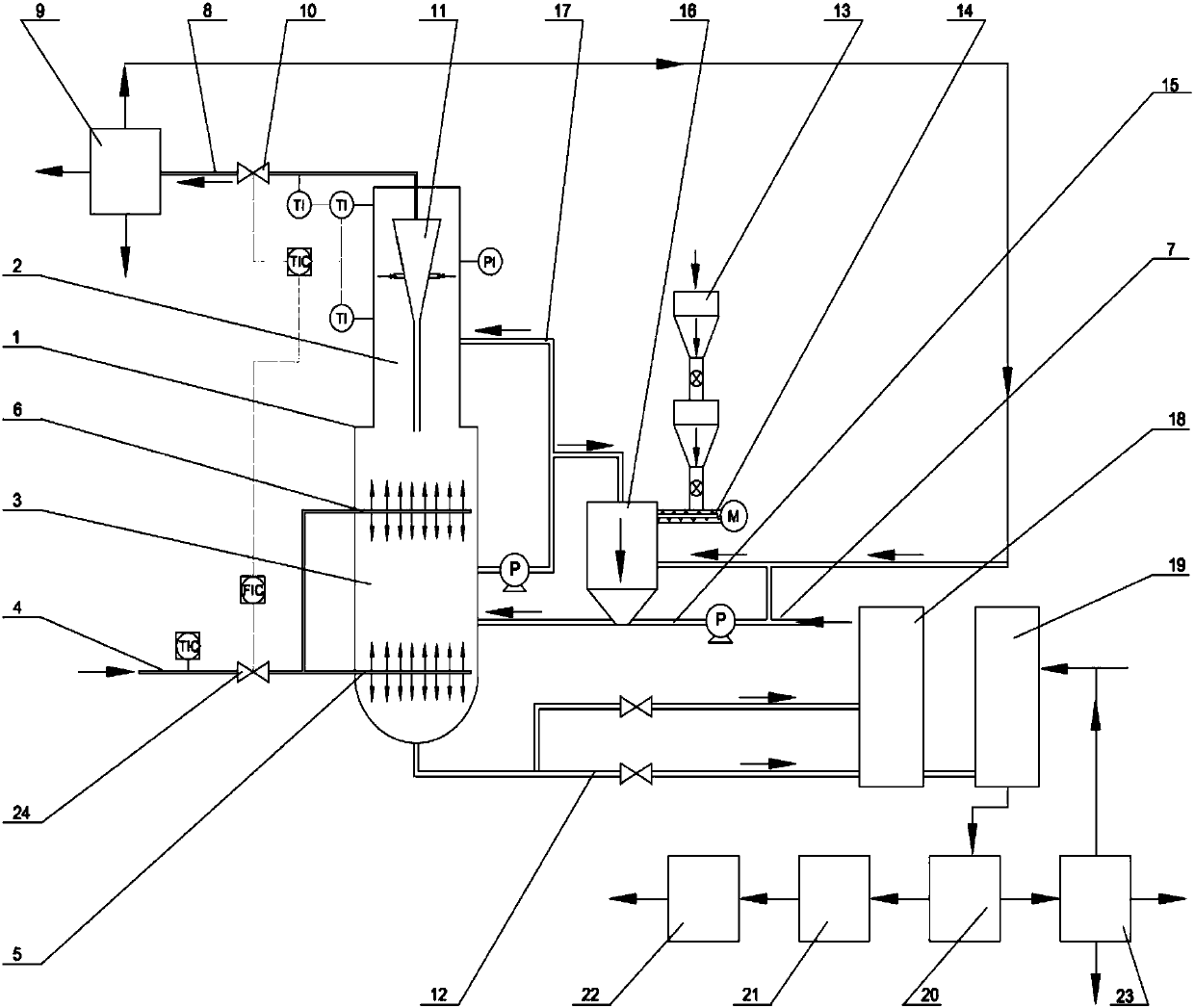

[0028] (Example 3, see figure 2 )

[0029] The difference between this embodiment and embodiment 1 is: wheat straw, FeCl 3 The mixture of acetic acid and isopropyl acetate is mixed in the dipping tank 16 to pretreat the raw materials, thereby improving the treatment effect and efficiency of the reactor, reducing the residence time of the material in the reactor, and improving the yield of furfural and pulp; premixing The material enters the mixing and cooking section 3 of the reactor, and is mixed with steam and heated in FeCl 3 Various reactions take place under the catalysis of acetic acid; the gas discharged from the outlet pipe 8 of the reactor enters the furfural rectification unit 9 to obtain furfural products, and the yield of furfural is greater than 70%. The acetic acid and isopropyl acetate are collected and returned to the catalyst solvent The feeding unit and the dipping tank are recycled; part of the liquid discharged from the lignin extraction unit is returned...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com