Method for preparing high Tg copper-clad plate

A technology of copper clad laminate and high molecular weight, which is applied in the field of preparation of high Tg copper clad laminate, to achieve the effects of improving resistance stability, solving cracking boards, and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

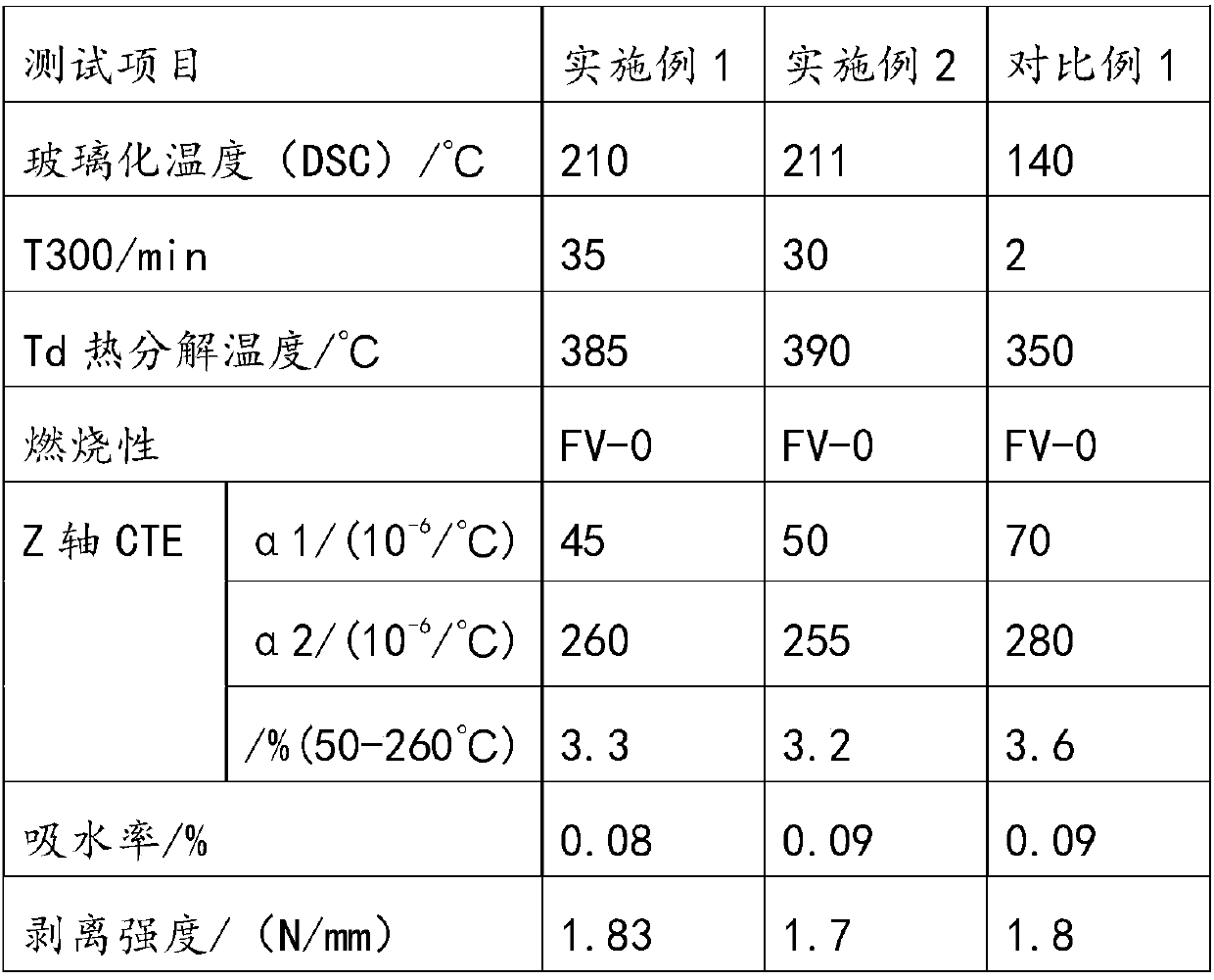

Examples

Embodiment 1

[0032] A preparation method of high Tg copper clad laminate, the steps are as follows:

[0033] (1) Preparation of glue solution: according to parts by weight, 8 parts of bisphenol F type epoxy resin, 20 parts of modified anhydride containing naphthalene ring, 20 parts of bisphenol F type brominated epoxy resin, tetraphenol ethane 5 parts of glycidyl ether, 3 parts of polyphenylene ether modified epoxy resin, 30 parts of naphthalene ring type benzoxazine resin, 20 parts of silicon micropowder and 20 parts of toluene are mixed to make glue;

[0034] (2) Use reinforcing material to dip the glue in step (1), and bake to make prepreg; under IPC standard detection, the prepreg reaches: fluidity 5-35%, gelation time 50-150s; prepreg air bubble content is: In the area of 4"*4", the diameter of the bubbles is ≤40μm, the number of bubbles with a diameter of 20-40μm is less than 2, and the number of bubbles with a diameter of 10-20μm is less than 5;

[0035] (3) Take 5 sheets of prep...

Embodiment 2

[0037] A preparation method of high Tg copper clad laminate, the steps are as follows:

[0038] (1) Preparation of glue: according to parts by weight, 9 parts of bisphenol A type epoxy resin, 18 parts of dicyclopentadiene maleic anhydride, 15 parts of bisphenol A type brominated epoxy resin, tetraphenol ethane 8 parts of glycidyl ether, 2 parts of isocyanate modified epoxy resin, 25 parts of bisphenol A benzoxazine resin and 25 parts of acetone are mixed to make glue;

[0039] (2) Use the reinforcing material to dip the glue in step (1), and bake it to make a prepreg; under the IPC standard test, the prepreg reaches: 5-35% fluidity, 50-150s gel time; the air bubble content of the prepreg is: In the area of 4"*4", the diameter of the bubbles is ≤40μm, the number of bubbles with a diameter of 20-40μm is less than 2, and the number of bubbles with a diameter of 10-20μm is less than 5;

[0040] (3) Take 5 sheets of prepregs and add metal foil on one side of the prepregs. The ro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com