White opacified glaze for jun porcelain

An opacifying glaze and white technology, applied in the field of Jun porcelain production, can solve the problems of low utilization rate of fly ash, high production cost, high cost, etc., achieve enhanced opacification effect, good opacification effect of glaze surface, high The effect of ornamental value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

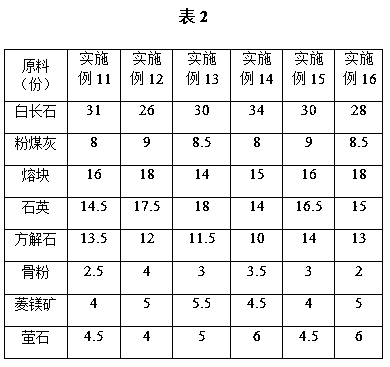

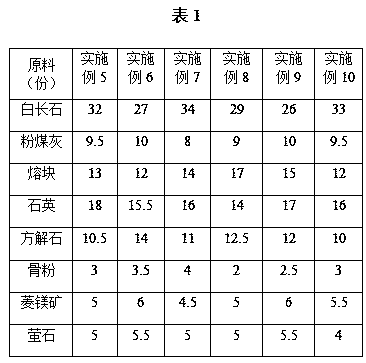

Examples

Embodiment 1

[0018] A white opaque glaze for Jun porcelain, prepared from the following raw materials in parts by weight: 26-34 parts by weight of white feldspar, 8-10 parts of fly ash, 12-18 parts of frit, 14-18 parts of quartz, 10-14 parts of calcite, and bone meal 2-4, magnesite 4-6, fluorite 4-6.

[0019] The used white feldspar, quartz, and calcite of the present invention are all taken from the local area of Yuzhou, and the fly ash is purchased from the local area (the chemical composition content of the used fly ash is SiO 2 43.9, Al 2 o 3 35.6, Fe 2 o 3 6.18, CaO 4.39, MgO 1.21, K 2 O 0.68, Na 2 O0.71), because fly ash contains a lot of incomplete combustion impurities and iron content, it is easy to cause glaze holes and black centers during firing, and it is easy to make the overall glaze surface yellowish brown or even black, but fly ash It is easy to generate fine air bubbles during firing, which can produce an opacifying effect; on the basis of this, on the one hand...

Embodiment 2

[0025] A white opaque glaze for Jun porcelain, prepared from the following raw materials in parts by weight: 30 parts by weight of white feldspar, 9 parts by fly ash, 15 parts by frit, 16 parts by quartz, 12 parts by calcite, 3 parts by weight of bone meal, 5 parts by weight of magnesite, and 5 parts by fluorite .

[0026] The preparation method of Jun porcelain white opaque glaze as mentioned above comprises the following steps:

[0027] (1) Mix raw materials, remove iron, ball mill, and filter to obtain glaze slurry;

[0028] (2) Apply glaze to the body after bisque firing;

[0029] (3) Firing at 1280°C; the specific firing process is as follows: first, the temperature of the glazed green body is raised to 950°C evenly in 4 hours in an oxidizing atmosphere; then the temperature is raised to 1200°C in 6.5 hours in a reducing atmosphere ℃; Finally, under neutral fire, the temperature was evenly raised to 1280 ℃ in 4 hours; naturally cooled.

[0030] The glaze color of the p...

Embodiment 3

[0032] A white opaque glaze for Jun porcelain, prepared from the following raw materials in parts by weight: 30 parts by weight of white feldspar, 9 parts by fly ash, 15 parts by frit, 16 parts by quartz, 12 parts by calcite, 3 parts by weight of bone meal, 5 parts by weight of magnesite, and 5 parts by fluorite .

[0033] The preparation method of Jun porcelain white opaque glaze as mentioned above comprises the following steps:

[0034] (1) Mix raw materials, remove iron, ball mill, and filter to obtain glaze slurry;

[0035] (2) Apply glaze to the body after bisque firing;

[0036] (3) Firing at 1290°C; the specific firing process is as follows: first, the temperature of the glazed green body is raised to 970°C in 4 hours in an oxidizing atmosphere; then in a reducing atmosphere, the temperature is evenly raised to 1220°C in 7 hours ; Finally, under a neutral fire, the temperature was evenly raised to 1290 ° C in 4 hours; natural cooling.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com