Device and technology for synthesis of aromatic polyester polyol

An aromatic polyester and polyol technology, applied in the field of polyester polyol, can solve the problems of polyol loss, poor product specifications of polyester polyol, high process energy consumption, etc., to reduce the content, improve product performance indicators, good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

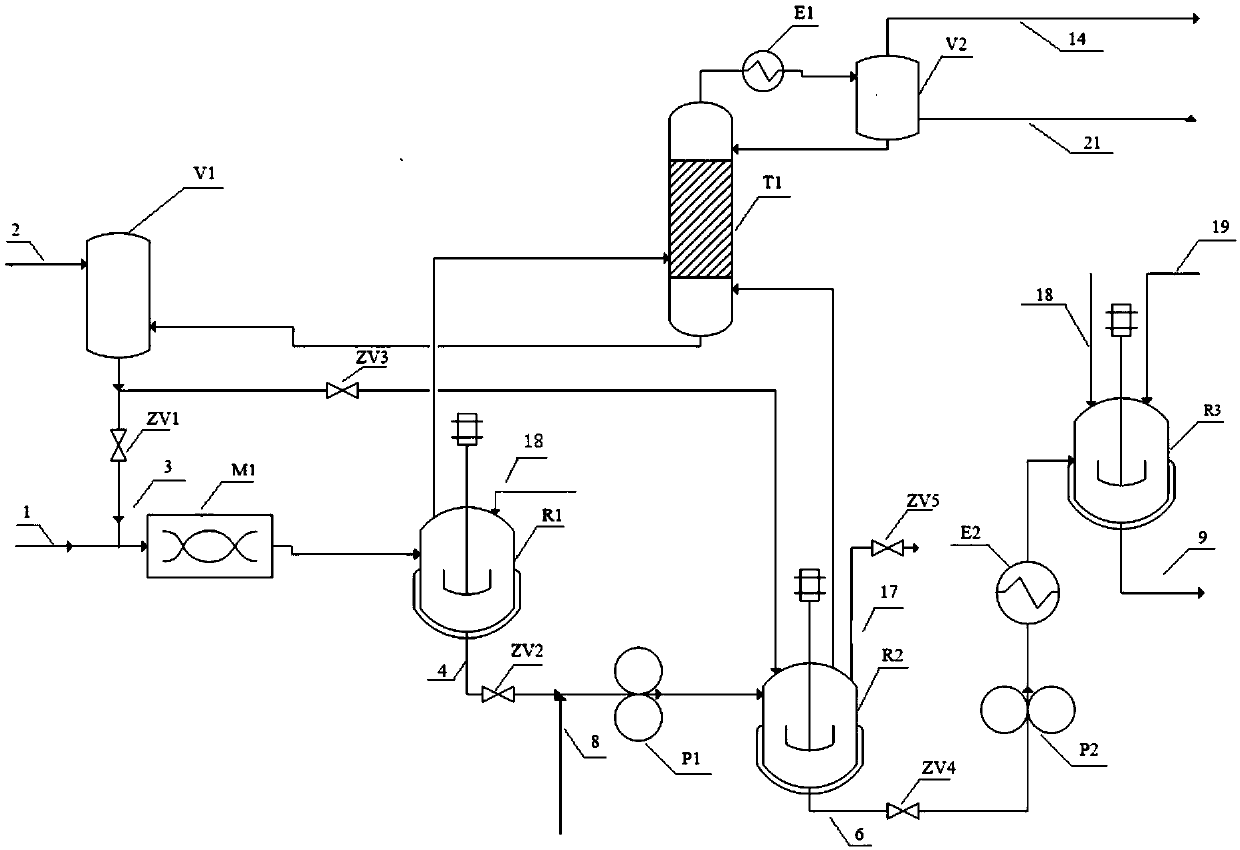

[0033] Embodiment 1: as figure 1 As shown, an aromatic polyester polyol synthesis device includes a mixer, a polyol intermediate tank, an esterification reactor, a polycondensation reactor, an intermediate heat exchanger, a blending reactor, a polyol recovery tower, and a tower top condensation device, tower top reflux tank, control valve group and transfer pump;

[0034] The mixer is provided with an organic carboxylic acid feed port, a mixer polyol feed port and a mixer discharge port, and the polyol intermediate tank is provided with a fresh polyol feed port, a recycled polyol feed port and The polyol discharge port of the tundish tank, the polyol discharge port of the tundish tank is connected to the polyol feed port of the mixer, and the connecting pipe is provided with a first control valve group;

[0035] The top of the esterification reactor is provided with a gas phase outlet of the esterification reactor, an inert gas inlet of the esterification reactor, and a feed ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hydroxyl value | aaaaa | aaaaa |

| acid value | aaaaa | aaaaa |

| hydroxyl value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com