A helical carbon nanofiber/TiO2 composite material and application thereof

A nano-carbon fiber and composite material technology, applied in the direction of hybrid capacitor electrodes, etc., can solve the problems of low energy density, small specific surface area of electrode materials, poor interface bonding force of composite electrodes, etc., to increase specific surface area, improve effective contact area, improve The effect of binding capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

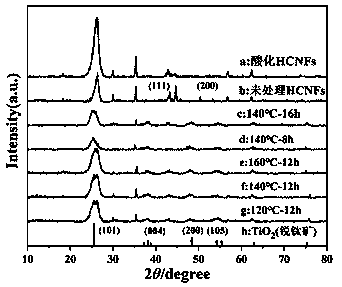

[0036] 1) Weigh 0.2 g of copper tartrate trihydrate and place it in a quartz boat, spread it evenly, place it in the heating tube of the device, then pass in argon gas to remove the air in the tube, and heat up to 480 °C at 5 °C / min , and then feed acetylene at a flow rate of 80 ml / min, and keep warm for 2 hours. After the reaction is finished, turn off the acetylene, pass through the argon gas protection, cool down to room temperature with the furnace, take out the sample, and obtain the helical carbon nanofiber.

[0037] 2) Take 3 g of helical carbon nanofibers (HCNFs) prepared in step 1) and add them to a concentrated nitric acid solution with a mass fraction of 68%, in a water-bath ultrasonic instrument, 40KHz ultrasonic treatment for 2 hours, then add a large amount of distilled water, and then pass through the sand core The funnel was filtered and washed repeatedly with ethanol solution until the supernatant was neutral (pH=7). Finally, the product was vacuum-dried in an...

Embodiment 2

[0041] 1) Weigh 0.2 g of copper tartrate trihydrate and place it in a quartz boat, spread it evenly, place it in the heating tube of the device, then pass in argon gas to remove the air in the tube, and heat up to 480 °C at 5 °C / min , turn off the argon, and then pass through acetylene at a flow rate of 100ml / min, and keep warm for 2h. After the reaction was over, the acetylene was turned off, argon was introduced, and the furnace was cooled to room temperature, and the samples were taken out to obtain helical carbon nanofibers (HCNFs).

[0042] 2) Take 3 g of helical carbon nanofibers (HCNFs) prepared in step 1) and add them to a concentrated nitric acid solution with a mass fraction of 68%, in a water-bath ultrasonic instrument, 40KHz ultrasonic treatment for 2 hours, then add a large amount of distilled water, and then pass through the sand core The funnel was filtered and washed repeatedly with ethanol solution until the supernatant was neutral (pH=7). Finally, the product...

Embodiment 3

[0046] 1) Weigh 0.2 g of copper tartrate trihydrate and place it in a quartz boat, spread it evenly, place it in the heating tube of the device, then pass in argon gas to remove the air in the tube, and heat up to 480 °C at 5 °C / min , turn off the argon, and then pass through acetylene at a flow rate of 100ml / min, and keep warm for 2h. After the reaction is finished, turn off the acetylene, pass through the argon gas protection, cool down to room temperature with the furnace, take out the sample, and obtain the helical carbon nanofiber.

[0047] 2) Take 3 g of helical carbon nanofibers (HCNFs) prepared in step 1) and add them to a concentrated nitric acid solution with a mass fraction of 68%, in a water-bath ultrasonic instrument, 40KHz ultrasonic treatment for 2 hours, then add a large amount of distilled water, and then pass through the sand core The funnel was filtered and washed repeatedly with ethanol solution until the supernatant was neutral (pH=7). Finally, the product...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com