Cigarette holder filtering material and preparation method thereof

A technology for filtering materials and cigarettes, which is applied in the fields of tobacco, tobacco processing, application, etc., can solve the problems of unable to meet various needs, single function, etc., and achieve the effect of good adsorption effect, reduction of HCN, and improvement of utilization efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

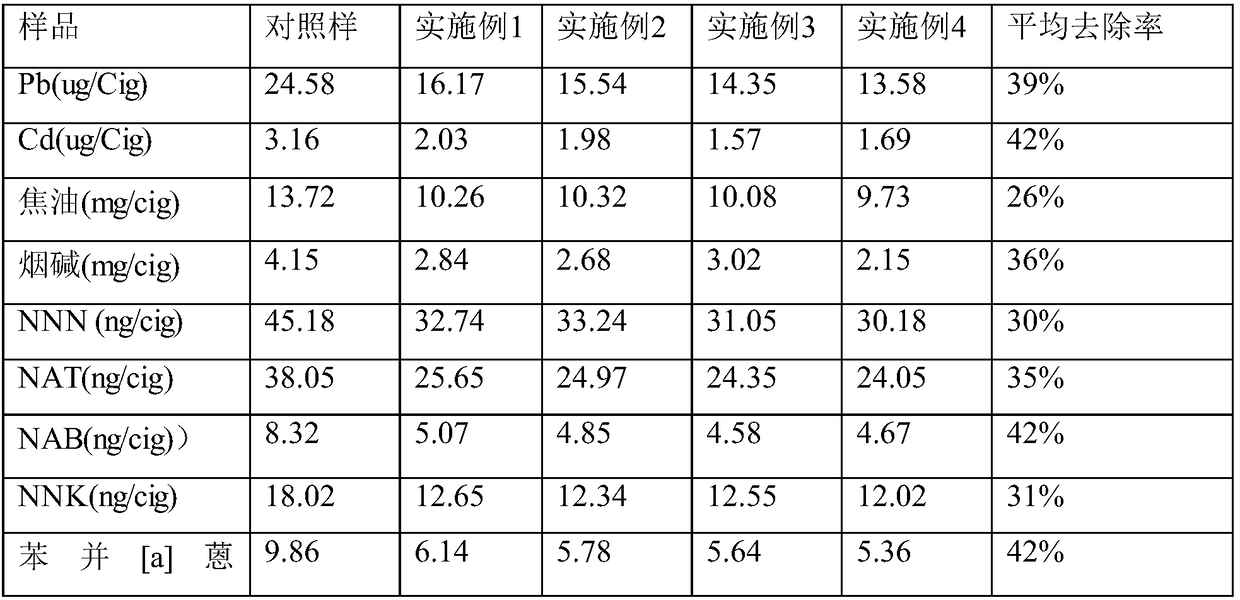

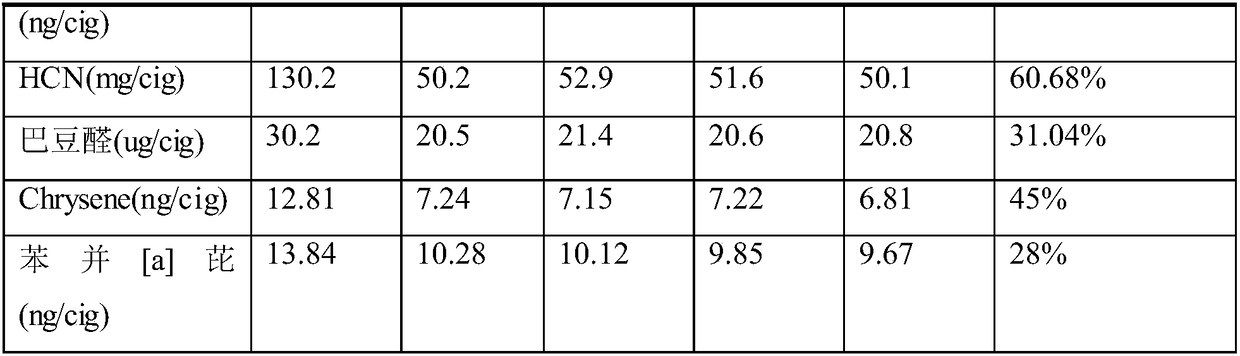

Examples

Embodiment 1

[0042] Get peanut shells, crush them to 50 mesh, add 5 times the mass of peanut shells in deionized water, soak for 5 hours, filter, discard soluble impurities, and dry at 50°C to obtain peanut shell powder; get peanut shell powder, according to the peanut shell powder ( g) and nitric acid solution (ml) at a ratio of 0.5:4, add nitric acid solution with a mass fraction concentration of 5%, heat in a water bath at a temperature of 50°C, stir evenly for 10 hours, cool to room temperature, filter, discard the filtrate, and use Wash the filter residue with deionized water until neutral, and dry at 50°C to obtain activated peanut shell powder;

[0043] Take activated peanut shell powder, add 5% sodium chloride solution in mass fraction concentration, stir evenly, add dropwise sodium silicate aqueous solution with 5% mass fraction concentration, the mass ratio of sodium silicate, sodium chloride and activated peanut shell powder is 1:1:1, stir for 0.5 hours, mix evenly, slowly add 5...

Embodiment 2

[0046] Get peanut shells, crush them to 200 mesh, add 10 times the mass of peanut shells in deionized water and soak for 5 hours, filter, discard soluble impurities, and dry at 100°C to obtain peanut shell powder; get peanut shell powder, according to the peanut shell powder ( g) The ratio of nitric acid solution (ml) is 2:6, add nitric acid solution with a mass fraction concentration of 15%, heat in a water bath at a temperature of 100°C, stir evenly for 5 hours, cool to room temperature, filter, discard the filtrate, and deionize Wash the filter residue with water until neutral, and dry at 100°C to obtain activated peanut shell powder;

[0047] Take activated peanut shell powder, add 20% mass fraction concentration sodium chloride solution, stir evenly, dropwise add mass fraction concentration 20% sodium silicate aqueous solution, the mass ratio of sodium silicate, sodium chloride and activated peanut shell powder is 1 :1:10, stir for 2 hours, mix evenly, slowly add hydrochl...

Embodiment 3

[0050] Take peanut shells, crush them to 100 mesh, add deionized water, the mass ratio of peanut shells to deionized water is 1:7; soak for 3 hours, filter, discard soluble impurities, and dry at 70°C to obtain peanut shell powder Take peanut shell powder, according to the ratio of 1:5 between peanut shell powder (g) and nitric acid solution (ml), add nitric acid solution with a mass fraction concentration of 5%, heat in a water bath at a temperature of 70°C, and stir evenly for 6 hours , cooled to room temperature, filtered, discarded the filtrate, washed the filter residue with deionized water until neutral, and dried at 70°C to obtain activated peanut shell powder;

[0051] Take activated peanut shell powder, add 10% sodium chloride solution, stir evenly, add dropwise 10% sodium silicate aqueous solution, the mass ratio of sodium silicate, sodium chloride and activated peanut shell powder is 1:1:5, stir After 1 hour, mix evenly, add 10% hydrochloric acid dropwise, adjust th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com