A method for preparing main vitellin from sea cucumber body cavity fluid

A technology of yolk protein and coelom fluid, which is applied in the preparation methods of peptides, chemical instruments and methods, peptide sources, etc., can solve the problems of waste of resources, environment, pollution, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

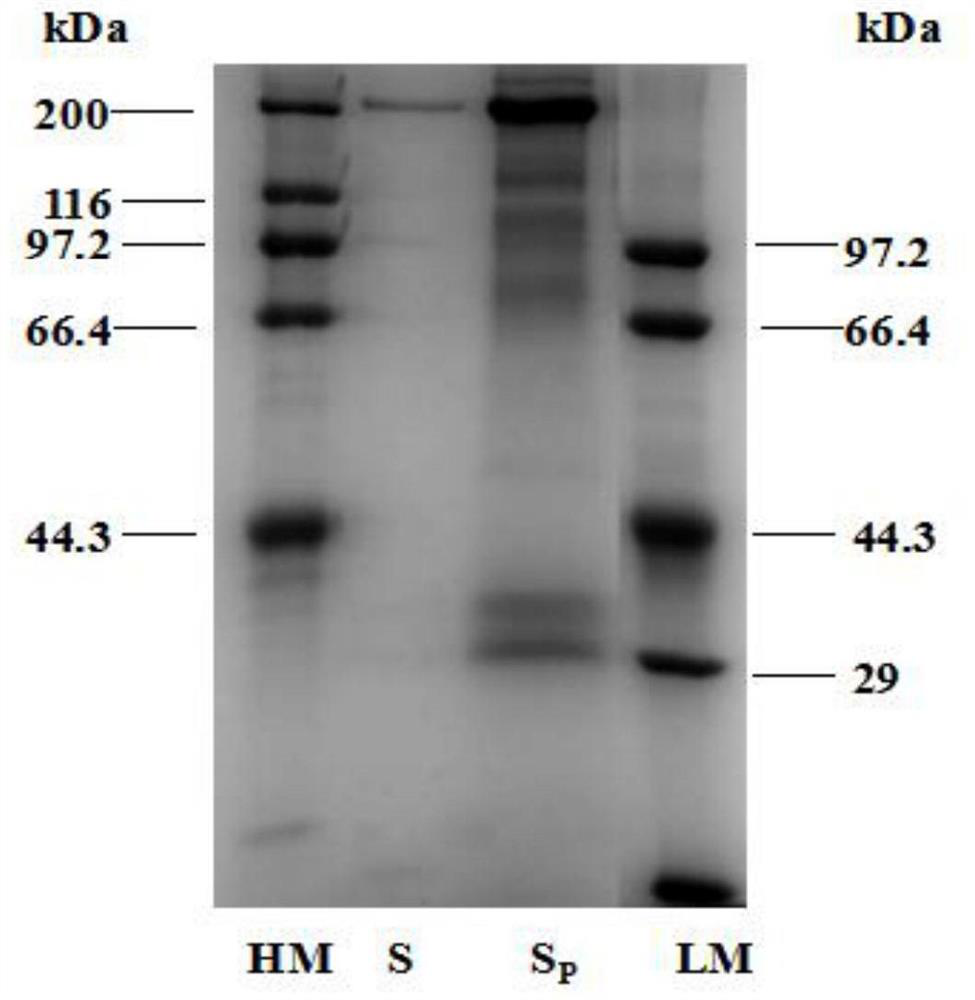

Image

Examples

Embodiment 1

[0034]S1, seatron body cavity pretreatment: Using filter paper to dry the liquid, the seafood is cut from the abdomen, collect the body cavity, centrifuge at 4 ° C, 1500 × g, collect the supernatant, to the body cavity Liquid;

[0035]S2, dialysis method low temperature removal salt: The phosphate buffer solution of 10 mM pH7 is dialyzed 48 h at 4 ° C for 4 ° C, and the amount of phosphate buffer is 10 times;

[0036]S3, extracting the main yoghuine: Under 4 ° C, the polyethylene glycol of the molecular weight 6000 is added to the seatrogan cavity liquid obtained by step S2, and the final concentration of the polyethylene glycol is 10% (weight), using 0.5 mol. / L NaOH solution or 0.5 mol / L of hydrochloric acid solution adjusted the reaction system pH of 7.0, standing for 3 h, 7500 g from centrifugation for 10 min, the resulting precipitate as the main yoglogin;

[0037]S4, reconstition: The primary peclancin precipitate obtained by step S3 is reconstituted with 10 mm pH 7.0 of a phosphate...

Embodiment 2

[0043]S1, seatrovic cavity pretreatment: Use filter paper to dry the liquid, cut the sea cucumber from the abdomen, collect the body cavity, centrifuge at 4 ° C, 2000 × g from 10 min, collect the supernatant, to the body cavity Liquid;

[0044]S2, dialysis method, low temperature removal salt: using a 3.5 kDa dialysis film, 20 mM pH 7.4 phosphate buffer solution of 20 mm pH 7 ° C for dialysis 60 h, and the amount of phosphate buffer is used as a body cavity. 15 times;

[0045]S3, extracting the main yoyangoprotein: Under 4 ° C, the polyethylene glycol of the molecular weight 6000 is added to the seatrogan cavity liquid obtained in step S2, so that the final concentration of the polyethylene glycol is 12% (weight), using 0.5 mol / L NaOH solution or 0.5 mol / L of hydrochloric acid solution adjusted the reaction system pH of 7.5, standing for 6 h, 8000 g from 20 min, and the resulting precipitate is the main yogglycin;

[0046]S4, reconstition: The primary peclancin precipitate obtained by st...

Embodiment 3

[0052]S1, seatron body cavity pretreatment: Use filter paper to dry the liquid, cut the sea cucumber from the abdomen, collect the body cavity, centrifuge at 4 ° C, 1800 × g conditions of 12 minutes, collect the supernatant, to the body cavity Liquid;

[0053]S2, dialysis method low-temperature salt: using 4 kDa dialysis film, 25 mM pH 8 phosphate buffer solution to dialysis 72 h, the amount of phosphate buffer is 20 times, control The temperature of the phosphate buffer solution temperature at 4 ° C

[0054]S3, extracting the main yoghuine: Under 4 ° C, add polyethylene glycol of molecular weight 6000 to the seatron cell cavity obtained in step S2, and the final concentration of polyethylene glycol is 14% by weight, 0.5 mol / L NaOH solution or 0.5 mol / L of hydrochloric acid solution adjusts the reaction system pH 8, stands for 9h, 8500 g from 15 min, the resulting precipitate is the main yoghuine protein

[0055]S4, reconstition: Pelletizing step S3 is reconstituted by 20 mL / g of a pho...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com