Seaweed fermented alga cake

A technology of seaweed and fermentation liquid, applied in the direction of microorganisms, fungi, biochemical equipment and methods, etc., can solve the problem that it is not suitable for industrial application, there are few research reports on biological deodorization technology, and it will destroy the typical aroma of asparagus algae Flavor and other issues, to achieve the effect of high-value processing and utilization, significant deodorization effect of seaweed, and significant aroma production ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

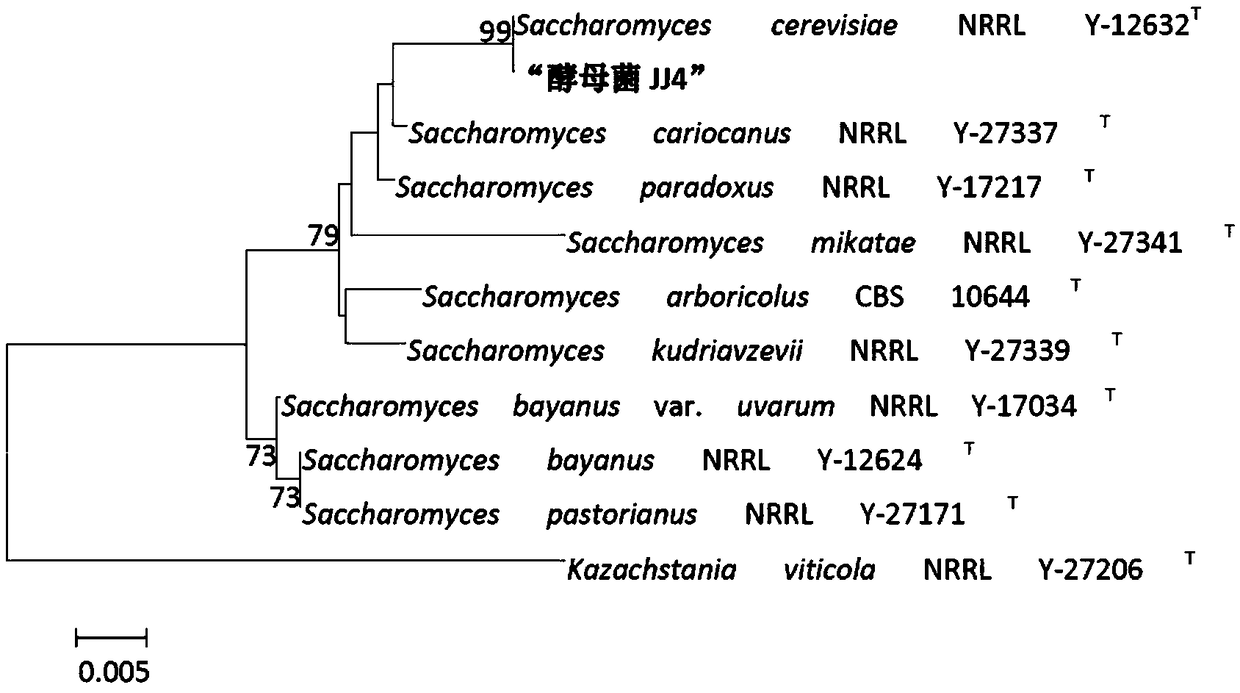

[0032] Isolation, screening, identification and preservation of the bacterial strain of embodiment 1

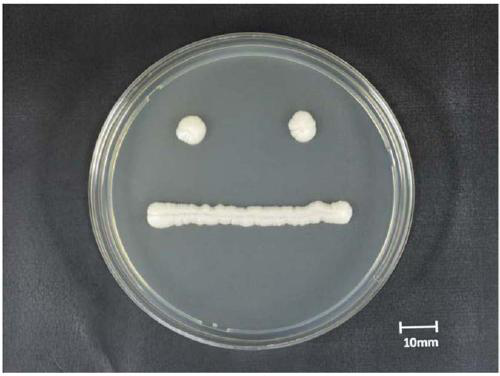

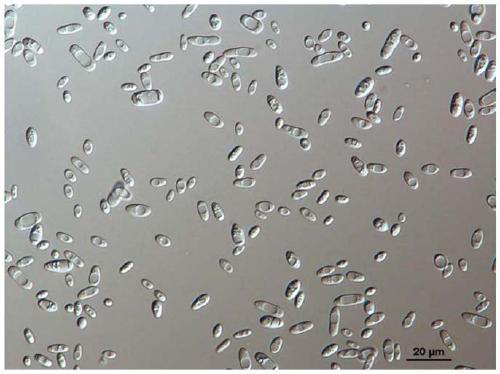

[0033] Yeasts were isolated from the fermented liquid of honeycomb samples with excellent flavor by plate streaking method; excellent yeasts with unique fermented flavor were screened out through fermentation flavor and brewing characteristics tests.

[0034] 1. Isolation and purification of strains

[0035] The honeycomb sample with excellent flavor is used as the source of the selected bacteria, which is serially diluted and spread on the yeast isolation and purification medium plate, and the purer strains are obtained through multiple streak separation and microscopic examination. According to the TTC color change test, 6 strains with typical yeast colony characteristics were selected, numbered JJ1, JJ2, JJ3, JJ4, JJ5, JJ6, and the obtained strains were inoculated on the wort slant medium, and cultured at 28°C for 1 day , 4 ℃ refrigerator preservation, spare.

[0036] 2....

Embodiment 2

[0066] Example 2: Saccharomyces cerevisiae JJ4 is used to remove fishy smell from asparagus

[0067] 1. Preparation of test group samples:

[0068] (1) Wash and drain the asparagus, cut into 4.5-5.5mm wide asparagus particles;

[0069] (2) According to the mass ratio of the asparagus granules and water being 1:2-5, add distilled water to the asparagus granules, stir evenly, beat until there are no obvious particles, and obtain the algal pulp;

[0070] (3) Add malic acid of 0.28-0.3% of Asparagus granules mass in the algae pulp (the purpose is to adjust the pH value to about 4.5, and this pH value is the optimum initial growth pH value of yeast), then add asparagus White granulated sugar with a mass of 4.5-5.5% mustard granules to obtain a compounded solution, which is heated and dissolved at 95°C-100°C, then divided into conical flasks, sterilized at 100°C for 10 minutes, and cooled;

[0071] (4) Cultivate Saccharomyces cerevisiae in molasses culture medium at 30°C for 24 ho...

Embodiment 3

[0097] The determination of the optimum fermentation condition of embodiment 3 Saccharomyces cerevisiae JJ4

[0098] 1 Materials and methods

[0099] 1.1 Materials

[0100] 1.1.1 Strains: Saccharomyces cerevisiae JJ4.

[0101] 1.1.2 Growth medium: YPD liquid medium.

[0102] 1.2 Main instruments and equipment

[0103] SPX-250BS-Ⅱ biochemical incubator: Shanghai Xinmiao Medical Instrument Manufacturing Co., Ltd.; HZP-250 full-temperature shaking incubator: Shanghai Jinghong Experimental Equipment Co., Ltd.; YXQ-CS-50SⅡ automatic vertical pressure steam sterilizer : Shanghai Boda Industrial Co., Ltd. Medical Equipment Factory; DHG-9123A electric heating constant temperature blast drying oven: Shanghai Jinghong Experimental Equipment Co., Ltd.; SW-CJ-1FD single-person single-sided purification workbench: Suzhou Purification Equipment Co., Ltd. Sartorius-BS electronic balance: Beijing Sartorius Instrument System Co., Ltd.

[0104] 1.3 Determination method

[0105] 1.3.1 Neph...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com