A processing technology of special-shaped fiber for making oil-absorbing felt

A special-shaped fiber and processing technology, which is applied in fiber treatment, fiber chemical characteristics, rayon manufacturing, etc., can solve the problems of non-woven fabrics such as reduced wear resistance, and achieve good wear resistance, small water absorption, and reduced density. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

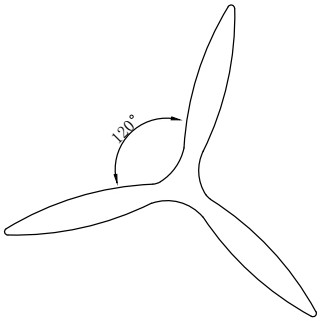

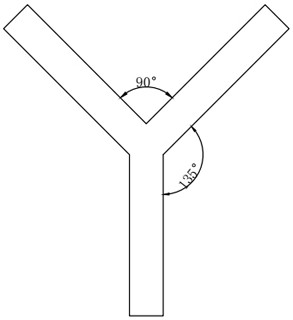

Image

Examples

Embodiment 1

[0025] A processing technology for producing special-shaped fibers for oil-absorbing felts, using modified polypropylene as a base material for processing, including the following steps:

[0026] (1) Wash, dry, crush, and sieve the loofah scoop to obtain loofah scoop powder with a particle size of 50 meshes, then completely immerse the loofah scoop powder in the treatment solution for ultrasonic treatment, and the ultrasonic temperature is 40 o C. Ultrasonic time is 40 minutes. Use clear water to clean the loofah scoop powder after ultrasonic treatment, and finally place it in a ventilated place to dry until the moisture content reaches 5%. The processed loofah scoop powder is ready for use;

[0027] (2) Add certain parts by mass of polypropylene resin, loofah powder, filler, compatibilizer, light stabilizer, flame retardant, and surfactant into a high-speed mixer and mix evenly to obtain a mixture;

[0028] (3) Add the mixture obtained in step (2) into a twin-screw extruder f...

Embodiment 2

[0038] A processing technology for producing special-shaped fibers for oil-absorbing felts, using modified polypropylene as a base material for processing, including the following steps:

[0039](1) Wash, dry, crush, and sieve the loofah scoop to obtain loofah scoop powder with a particle size of 80 mesh, and then completely immerse the loofah scoop powder in the treatment solution for ultrasonic treatment. The ultrasonic temperature is 35 o C. Ultrasonic time is 50 minutes. Use clear water to clean the loofah scoop powder after ultrasonic treatment, and finally place it in a ventilated place to dry until the moisture content reaches 5.5%. The processed loofah scoop powder is ready for use;

[0040] (2) Add certain parts by mass of polypropylene resin, loofah powder, filler, compatibilizer, light stabilizer, flame retardant, and surfactant into a high-speed mixer and mix evenly to obtain a mixture;

[0041] (3) Add the mixture obtained in step (2) into a twin-screw extruder fo...

Embodiment 3

[0051] A processing technology for producing special-shaped fibers for oil-absorbing felts, using modified polypropylene as a base material for processing, including the following steps:

[0052] (1) Clean, dry, crush, and sieve the loofah scoop to obtain loofah scoop powder with a particle size of 100 mesh, and then completely immerse the loofah scoop powder in the treatment solution for ultrasonic treatment. The ultrasonic temperature is 38 o C. Ultrasonic time is 55 minutes. Use clear water to clean the loofah scoop powder after ultrasonic treatment, and finally place it in a ventilated place to dry until the moisture content reaches 4%. The processed loofah scoop powder is ready for use;

[0053] (2) Add certain parts by mass of polypropylene resin, loofah powder, filler, compatibilizer, light stabilizer, flame retardant, and surfactant into a high-speed mixer and mix evenly to obtain a mixture;

[0054] (3) Add the mixture obtained in step (2) into a twin-screw extruder f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com