Anion surface active agent, detergent and detergent compound

A surfactant and anionic technology, applied in the field of anionic surfactants, detergents and detergent compositions, can solve the problem of poor emulsification, detergency, emulsion stability, foaming, etc., and large skin irritation to human body problem, to achieve excellent detergency, low skin irritation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] Sodium Lauryl Polytrioxyethylene Ether Sulfate (C 12 h 25 O(CH 2 CH 2 O) 3 SO 3 Na, referred to as AE 3 S) synthesis:

[0029] 1) Fill the kettle with nitrogen to discharge the air first, then add 1 mol of dodecyl alcohol polytrioxyethylene ether (Weibull distribution coefficient is 0.7), control the temperature of the reaction solution at 28°C, add 1.05 mol of chlorosulfonic acid dropwise while stirring, for 15 minutes After the dropwise addition of chlorosulfonic acid is completed, the constant temperature reaction is carried out for 1 hour, and the tail gas produced by the reaction is absorbed with NaOH solution;

[0030] 2) Measuring the acid value of the reaction solution, adding a 45% mass fraction of sodium hydroxide solution for neutralization, controlling the neutralization temperature to 40°C, and neutralizing to pH=7;

[0031] 3) Add ethanol at 65°C, filter, distill off the ethanol under reduced pressure, and cool to obtain sodium lauryl alcohol polytr...

Embodiment 2

[0048] Sodium tridecyl alcohol polytrioxyethylene ether acetate (C 13 h 27 O(CH 2 CH 2 O) 3 CH 2 COONa, referred to as AE 3 C) Synthesis of:

[0049] 1) Add 0.4mol isomeric tridecyl alcohol polytrioxyethylene ether (Weibull distribution coefficient is 0.7) to the flask, then add 0.22mol chloroacetic acid, stir and mix well, gradually heat up to 70°C, then add 0.44mol NaOH , constant temperature reaction for 0.5 hours;

[0050] 2) Add 0.22mol of chloroacetic acid and 0.44mol of NaOH, and react at constant temperature for 5 hours;

[0051] 3) After the reaction, add ethanol at 65°C, remove the generated sodium chloride and excess unreacted sodium chloroacetate by suction filtration, repeat the operation twice, remove the ethanol by distillation under reduced pressure, and cool to obtain isotridecyl alcohol polytrioxyethylene Sodium ether acetate (white viscous paste).

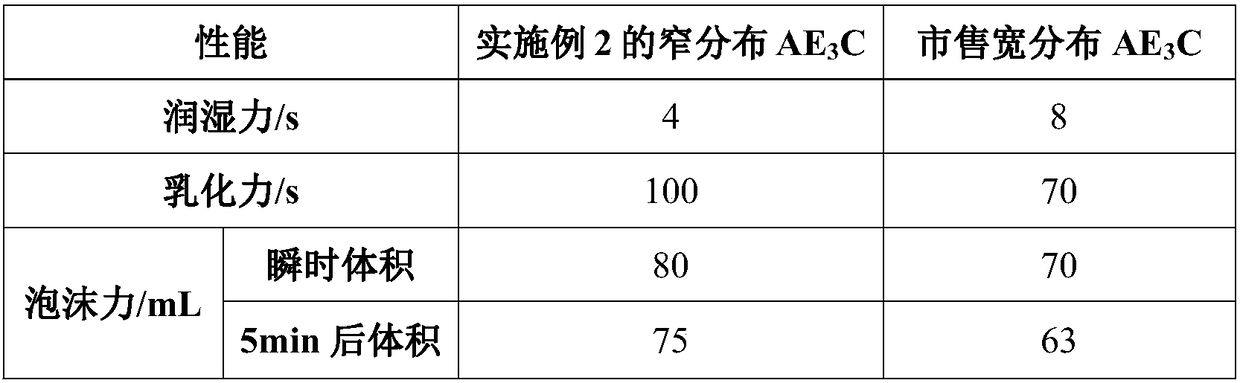

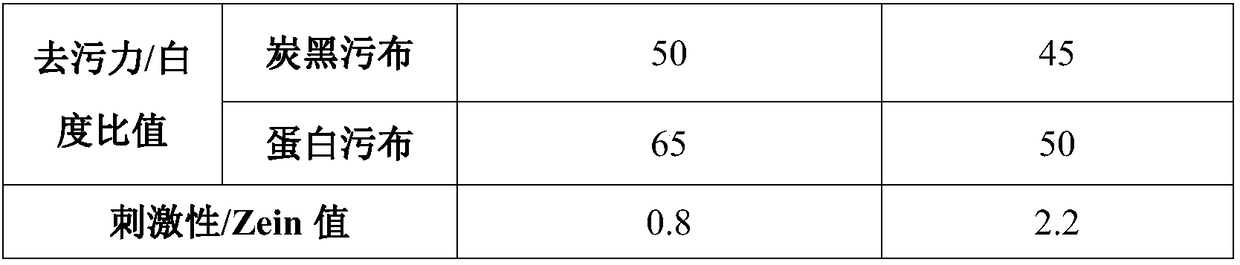

[0052] After testing, the Weibull distribution coefficient of the isotridecyl alcohol polytrioxyethyl...

Embodiment 3

[0059] Sodium Decyl Alcohol Polyoxyethylene Ether Sulfosuccinate (C 10 h 21 O(CH 2 CH 2 O) 2 COCH 2 CH(SO 3 Na)COONa, referred to as AE 2 SS) synthesis:

[0060] 1) Add 1 mol of decanol polyoxyethylene ether (Weibull distribution coefficient is 0.6) and 1.5 mol of maleic anhydride into the reactor, fill it with nitrogen, heat to a constant temperature of 55°C, stir slowly until the maleic anhydride melts, and then raise the temperature to 110 ℃ constant temperature reaction, take a sample every 0.5 hours to measure the acid value, and calculate the esterification rate, until the change of the acid value is less than 1mgKOH / g, stop the reaction;

[0061] 2) After the esterification reaction finishes, add dropwise Na with a mass fraction of 50% while stirring 2 SO 3 The solution was kept at a constant temperature of 110°C. Samples were regularly taken every 0.5 hours to measure the iodine value, and the sulfonation rate was calculated until the change in the sulfonation...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com