Metal nanoparticle/silicon dioxide composite light catalyst responded by visible light-near-infrared light

A technology of metal nanoparticles and silicon dioxide, which is applied in the direction of metal/metal oxide/metal hydroxide catalyst, physical/chemical process catalyst, oxidation to prepare carbonyl compounds, etc., can solve the problems of unfavorable utilization efficiency of metal atoms, and achieve Excellent photocatalytic activity, high catalytic efficiency, simple preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

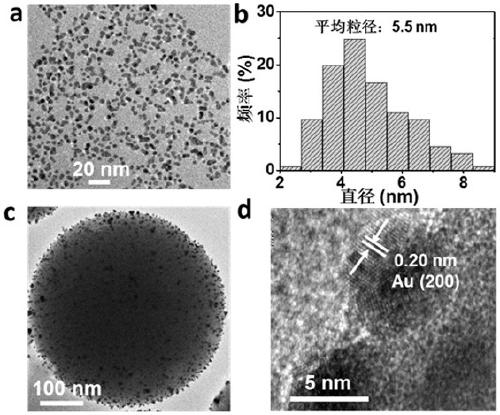

[0033] (1) SiO 2 Preparation: Add 2 ml tetraethyl silicate (TEOS) to 40 ml isopropanol, then add 1.4 ml ammonia water (NH 3 ·H 2 O), after reacting at room temperature for 4 h, the product was centrifuged, washed with ethanol and water, and dried at 60 °C to obtain spherical SiO 2 ;

[0034] (2) SiO 2 Modification: 200 mg of the obtained SiO 2 Disperse in 200 ml of ethanol, add 2 ml of 3-aminopropyltriethoxysilane (APTES), react at 60 °C for 4 h, centrifuge and wash to obtain SiO with a particle size of 450 nm and a positively charged surface 2 Microspheres;

[0035] (3) Preparation of Au NPs: Add 50 ml 0.4 mM chloroauric acid (HAuCl 4 ) solution, mix and add 5 ml of 12 mM sodium borohydride (NaBH 4 ), reacted for 2 h at room temperature to obtain AuNPs solution;

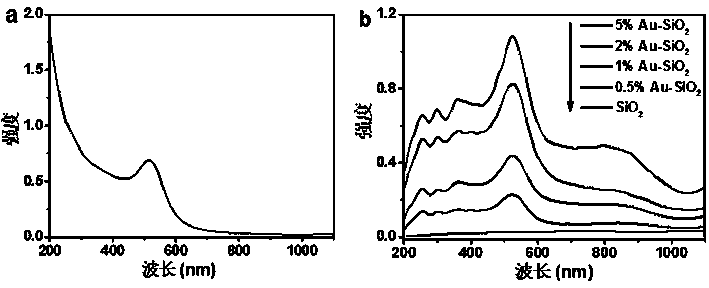

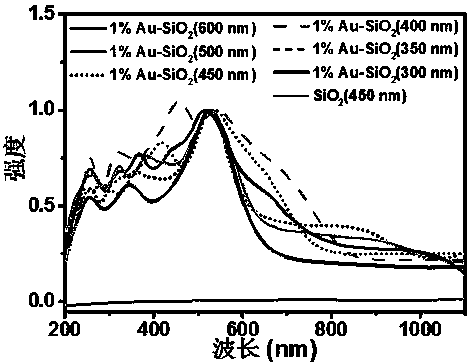

[0036] (4) Au / SiO2 2 Preparation: SiO obtained after modification 2 The microspheres were mixed with a certain amount of Au NPs solution and stirred for 2 h, and Au-SiO with Au NPs loadings of 0.5%, 1%, 2%...

Embodiment 2

[0040] (1) SiO 2 Preparation: Add 2 ml tetraethyl silicate (TEOS) to 40 ml isopropanol, add 0.4, 0.8, 1.2, 1.6, 1.8, 2 ml ammonia water (NH 3 ·H 2 O), after reacting at room temperature for 4 h, the product was centrifuged, washed with ethanol and water, and dried at 60 °C to obtain spherical SiO 2 ;

[0041] (2) SiO 2 Modification: 200 mg of the obtained SiO 2 Disperse in 200 ml of ethanol, add 2 ml of 3-aminopropyltriethoxysilane (APTES), react at 60 °C for 4 h, centrifuge and wash to obtain SiO with a particle size of 300-600 nm and a positively charged surface 2 Microspheres;

[0042] (3) Preparation of Au NPs: Add 50 ml 0.4 mM chloroauric acid (HAuCl 4 ) solution, mix and add 5 ml of 12 mM sodium borohydride (NaBH 4 ), reacted for 2 h at room temperature to obtain AuNPs solution;

[0043] (4) Au / SiO2 2 Preparation: SiO obtained after modification 2 The microspheres were mixed with a certain amount of Au NPs solution and stirred for 2 h, and SiO with different pa...

Embodiment 3

[0046] (1) SiO 2 Preparation: Add 2 ml tetraethyl silicate (TEOS) to 40 ml isopropanol, then add 1.4 ml ammonia water (NH 3 ·H 2 O), after reacting at room temperature for 4 h, the product was centrifuged, washed with ethanol and water, and dried at 60 °C to obtain spherical SiO 2 ;

[0047] (2) SiO 2 Modification: 200 mg of the obtained SiO 2 Disperse in 200 ml of ethanol, add 2 ml of 3-aminopropyltriethoxysilane (APTES), react at 60 °C for 4 h, centrifuge and wash to obtain SiO with a particle size of 450 nm and a positively charged surface 2 Microspheres;

[0048] (3) Preparation of Ag NPs: Add 50ml 0.4 mM silver nitrate (AgNO 3 ) solution, mix and add 5ml of 12 mM sodium borohydride (NaBH 4 ), reacted for 2 h at room temperature to obtain Ag NPs solution;

[0049] (4) Ag / SiO2 2 Preparation: SiO obtained after modification 2 The microspheres were mixed with a certain amount of Ag NPs solution and stirred for 2 h, and the Ag-SiO with a loading capacity of 1% was ob...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com